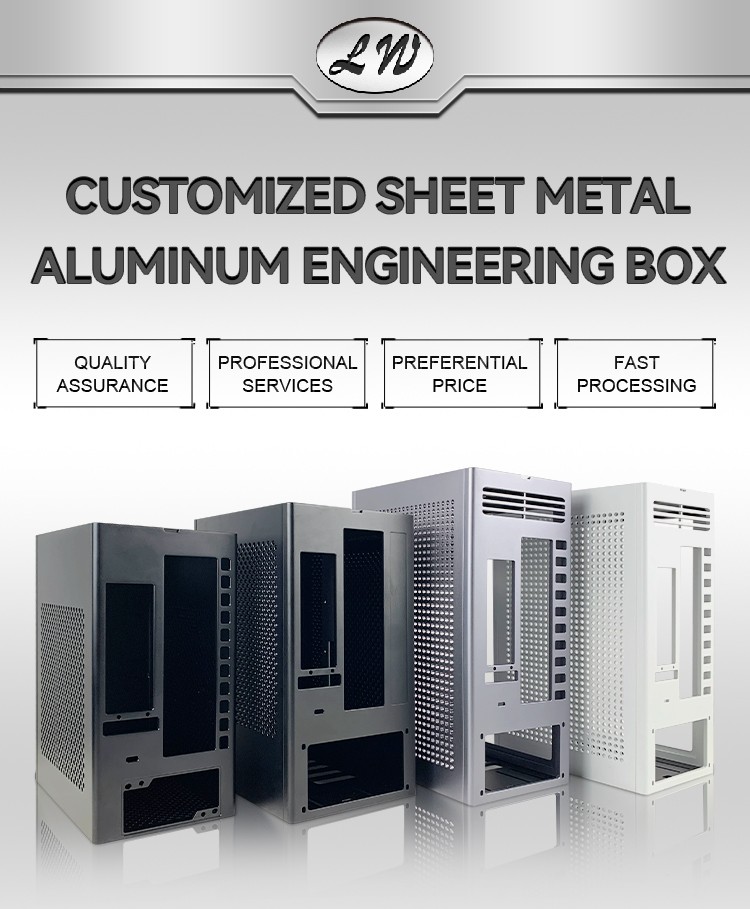

Sheet Metal Processing Mini Chassis Shell

Customized solutions for the entire industry chain from product material, design, production;

Focus on sheet metal chassis cabinet shell processing for 14 years.

Custom Manufacturing Sheet Metal Fabrication Aluminum Project Box Case Prototyping Electronic Enclosure

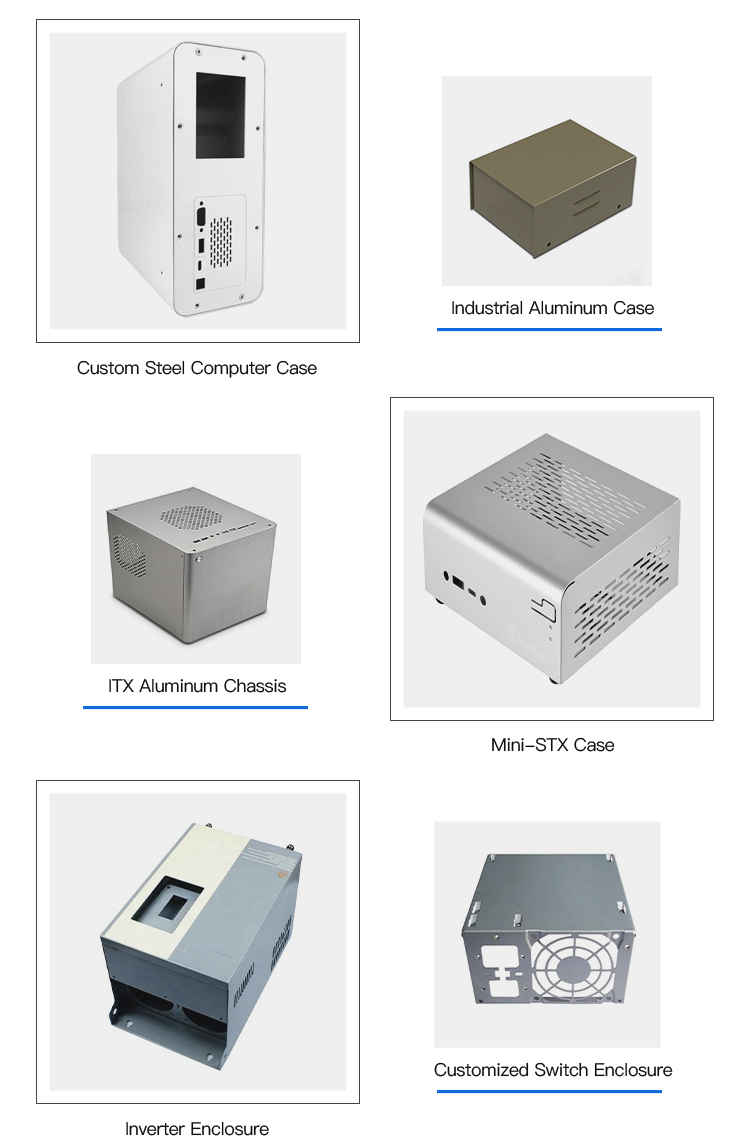

A premium Sheet Metal Computer Case, we crafted it with care. The details are handled in place, the surface is smooth and flat, bright and beautiful, and a feeling of ingenuity and craftsmanship emerges spontaneously. Seiko handles the details of the edges, all aspects are smooth and smooth without roughness, and great quality can be seen in small details.

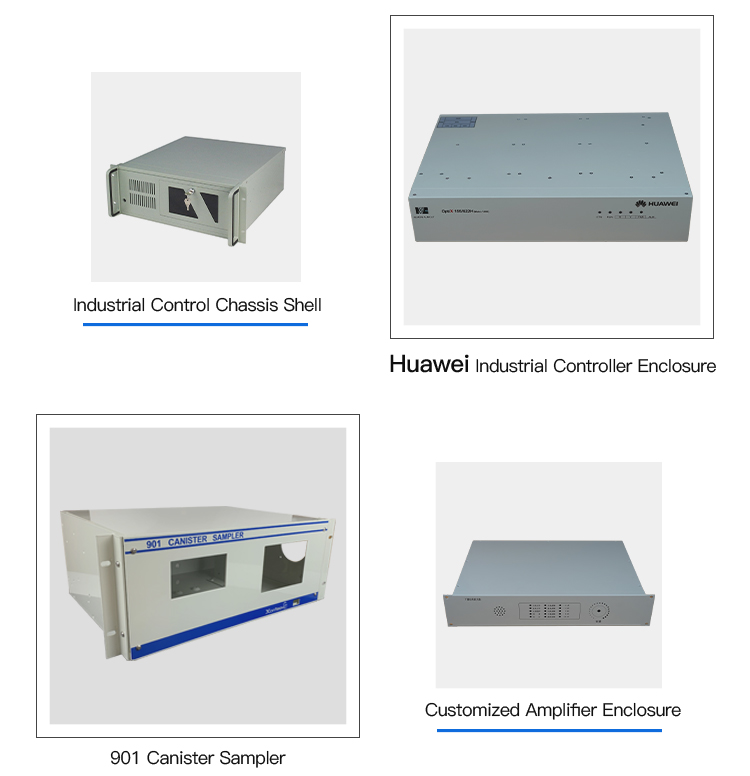

We can also provide Custom Sheet Metal Computer Case. We have our own sheet metal factory, CNC factory and injection molding factory. With our advanced mold technology and engineering manufacturing strength, we can provide you with high-quality services. From the development and manufacture of molds, to the production and spraying of sheet metal, CNC customized production parts.

If you need Sheet Metal Computer Case Bending, you can also contact us. We have been focusing on the production industry for many years. The raw materials of our products are of stable quality, and they have passed through layers of quality inspections and are not easy to be damaged. A variety of specifications, styles, spot inventory, support drawing and sample customization, can be customized according to customer needs.

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T, etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1, TA2/GR2, TA4/GR5, TC4, TC18, etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM, Acrylic, PC, etc. | |

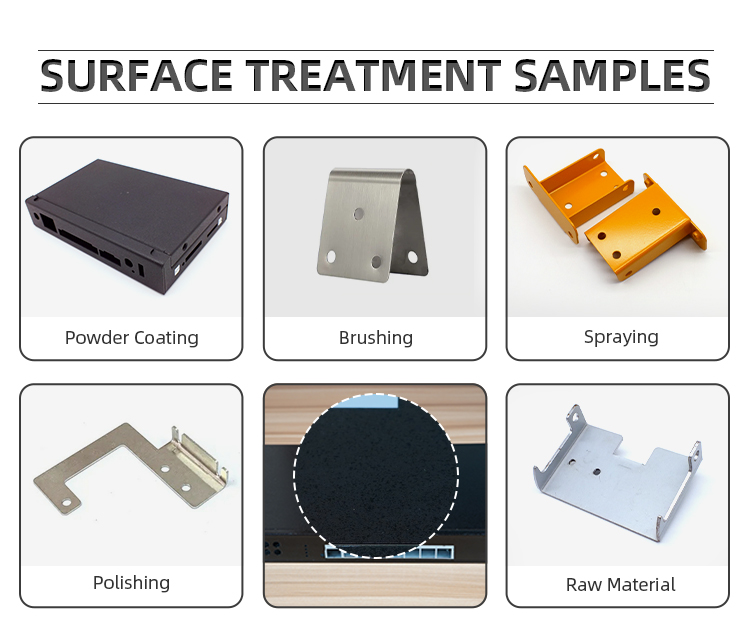

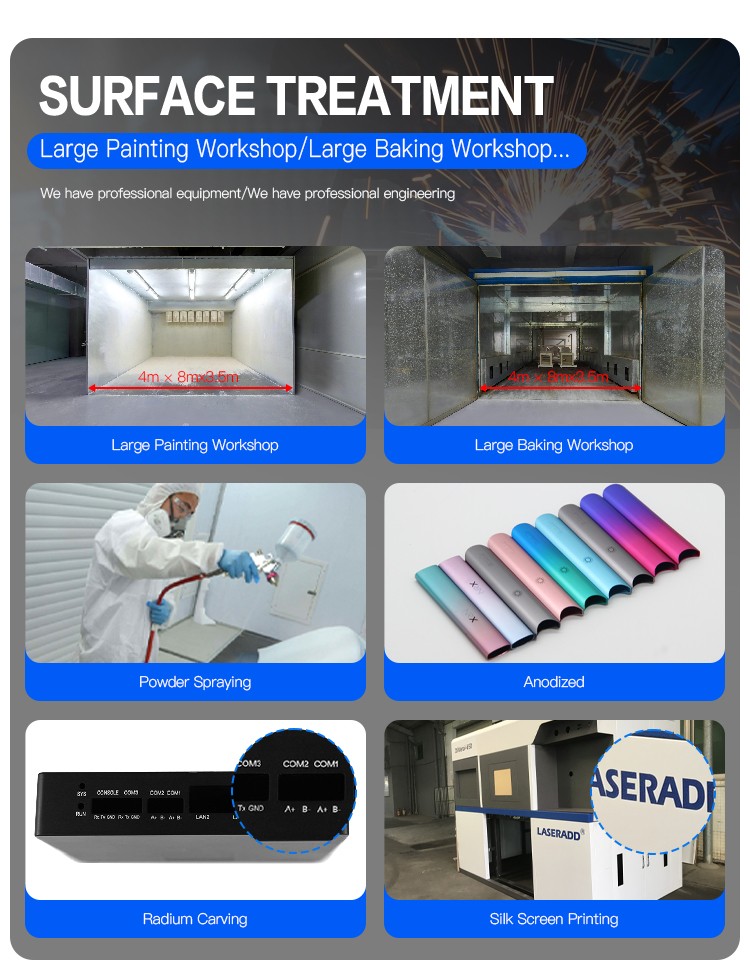

| Finish | Sandblasting, Anodized color, Blackening, Zinc/Nickl Plating, Polish, |

| Powder coating, Passivation PVD, Titanium Plating, Electro galvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing, Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling Machine, Laser Cutting Machine, etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

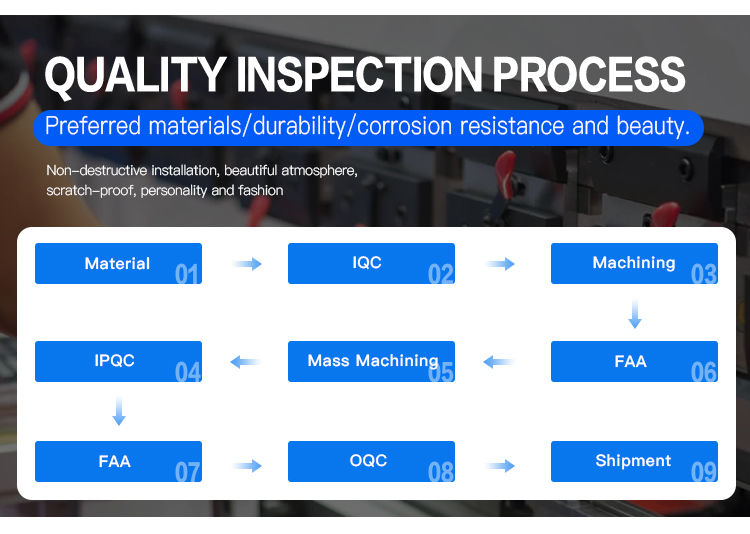

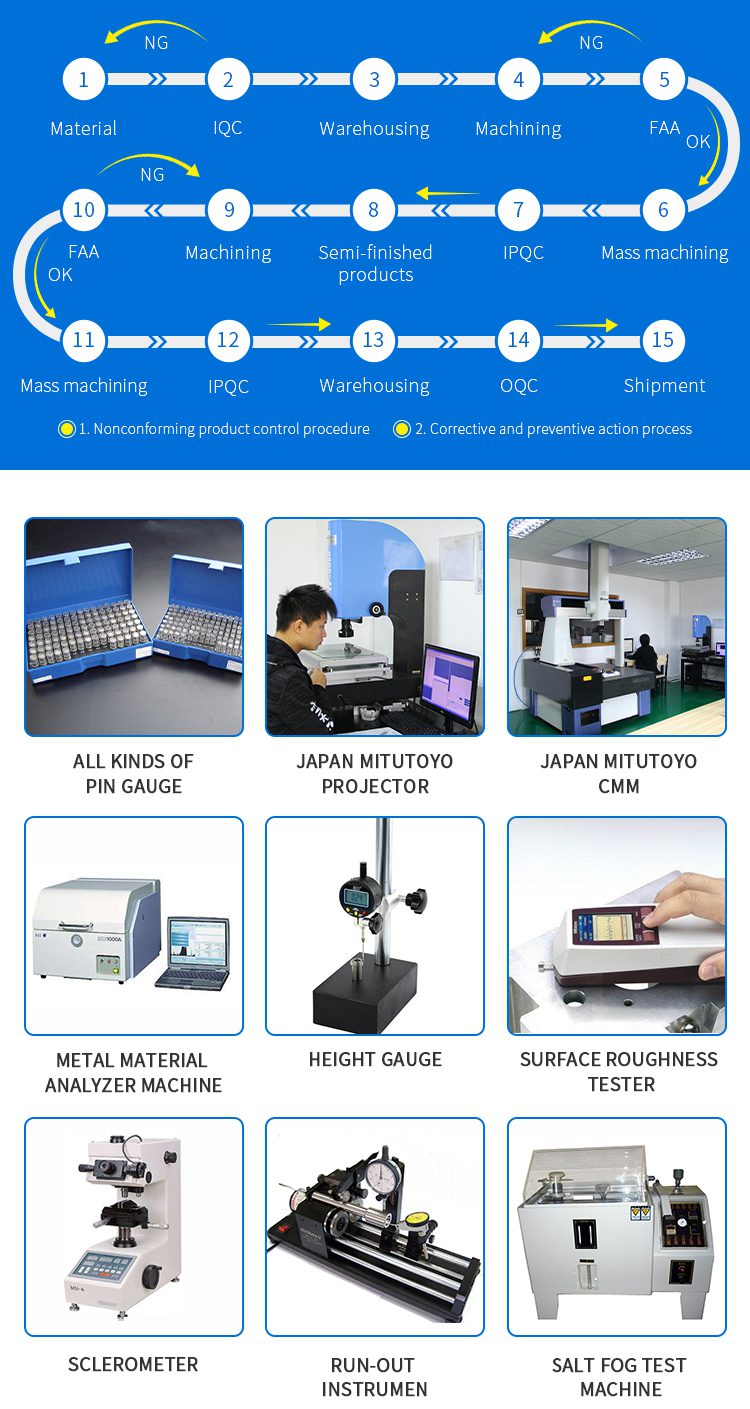

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier, CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |