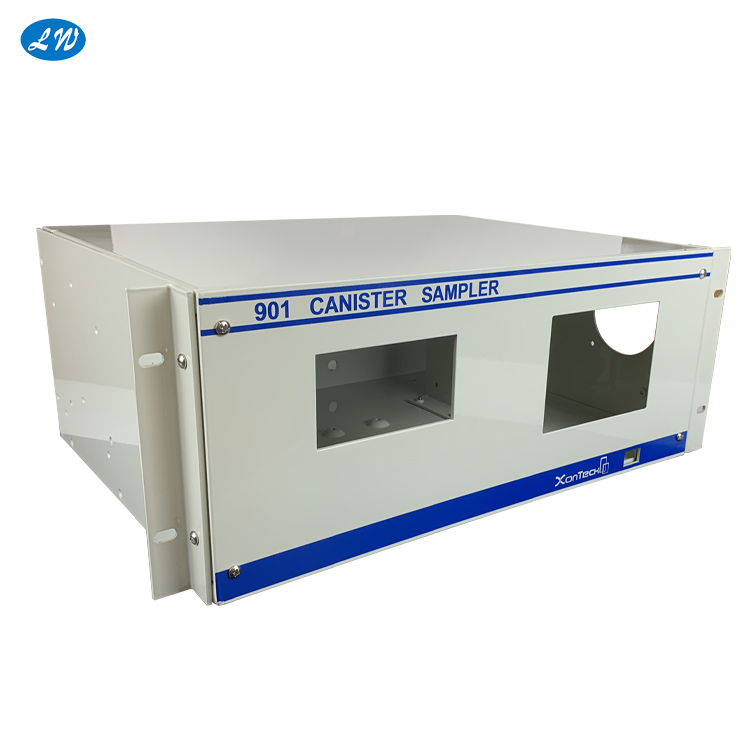

Metal Electronic Project Enclosure Box Case

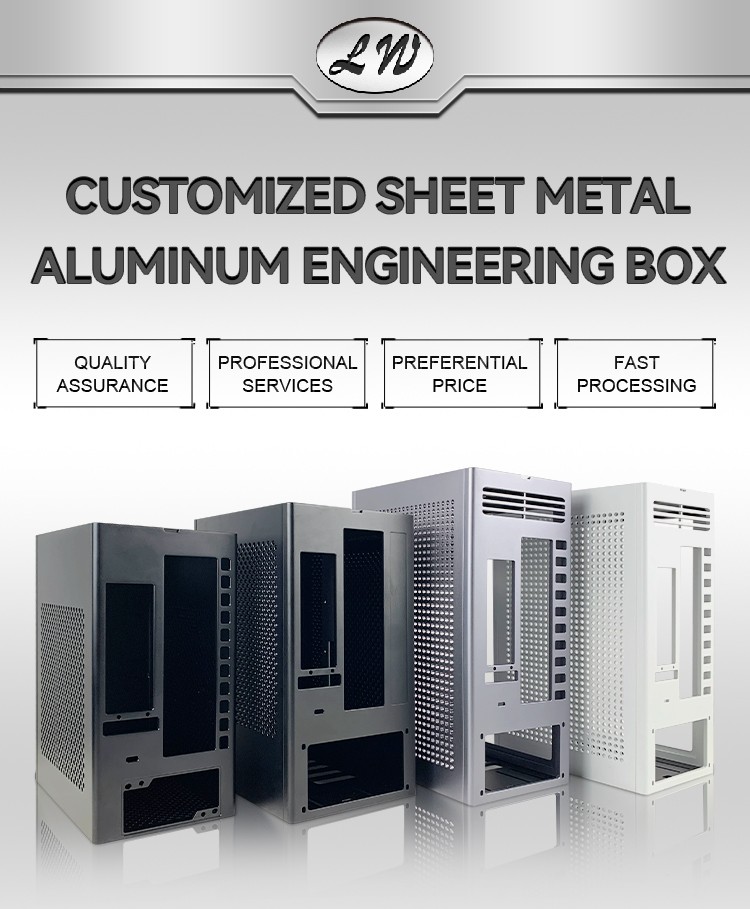

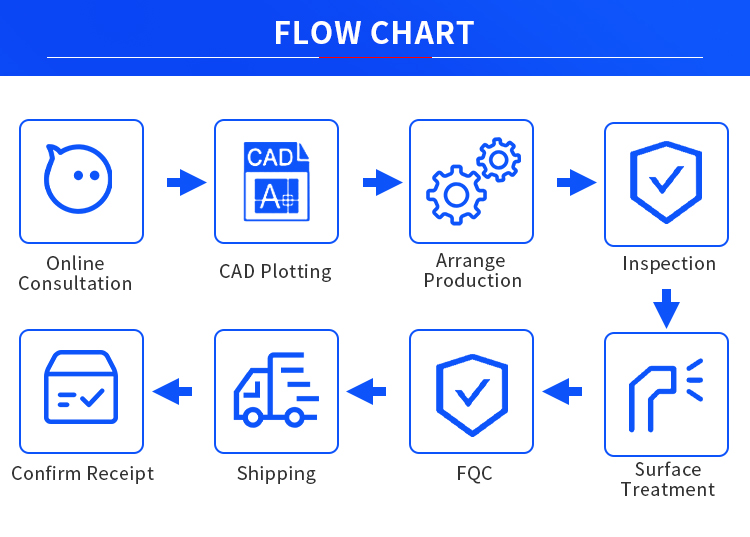

Customized solutions for the entire industry chain from product material, design, production;

Focus on sheet metal chassis cabinet shell processing for 14 years.

Custom Manufacturing Sheet Metal Fabrication Aluminum Project Box Case Prototyping Electronic Enclosure

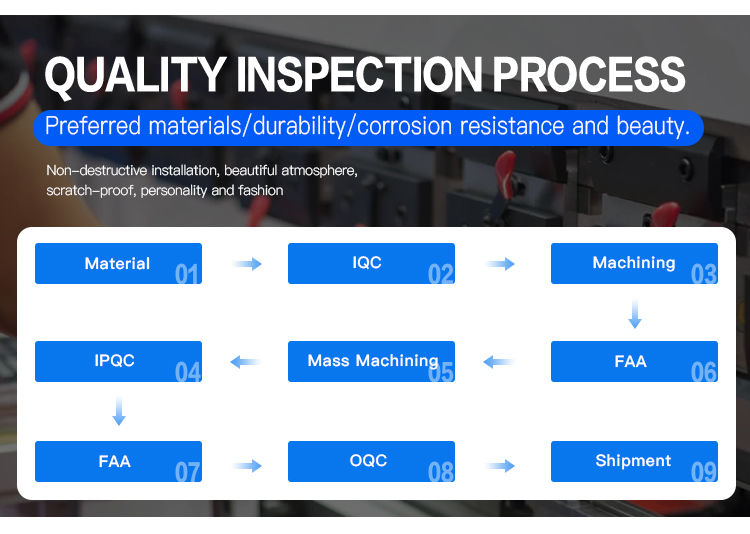

Fine design, excellence, production fine to every detail. Our technical innovation, complex and difficult surface and functional structural prototype models can be quickly prototyped and maintain precise originality. We have Sheet Metal Cabinet for sale, using real materials and refusing to cut corners. Good and durable.

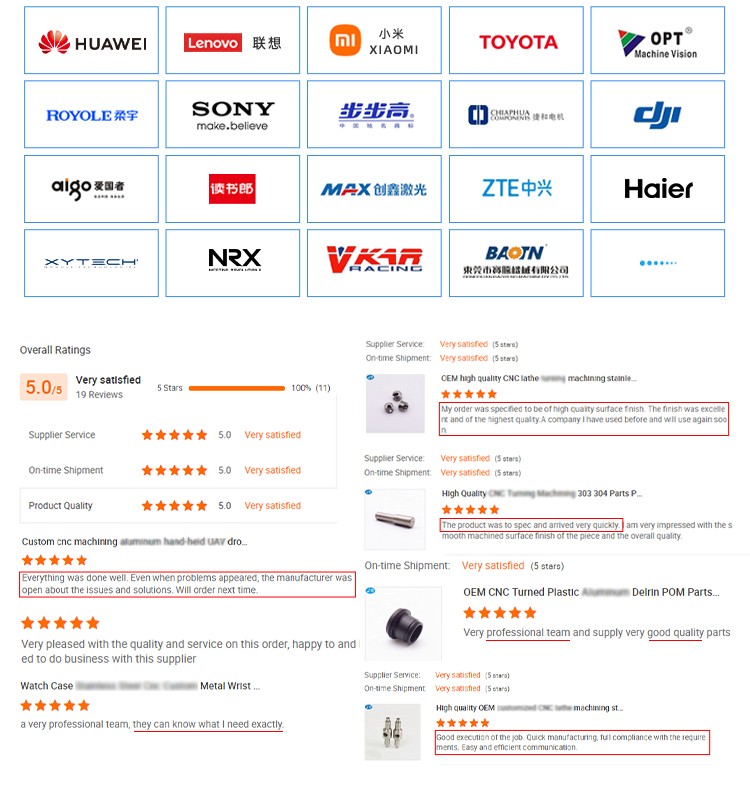

Factory direct sales, quality assurance, cost-effective. According to the needs of customers, customize exclusive processing solutions. Mature processing technology, strict quality inspection of ex-factory products. We are a physical factory with professional equipment. We ship quickly and serve professionally. We have our own factory with complete equipment and rich experience.

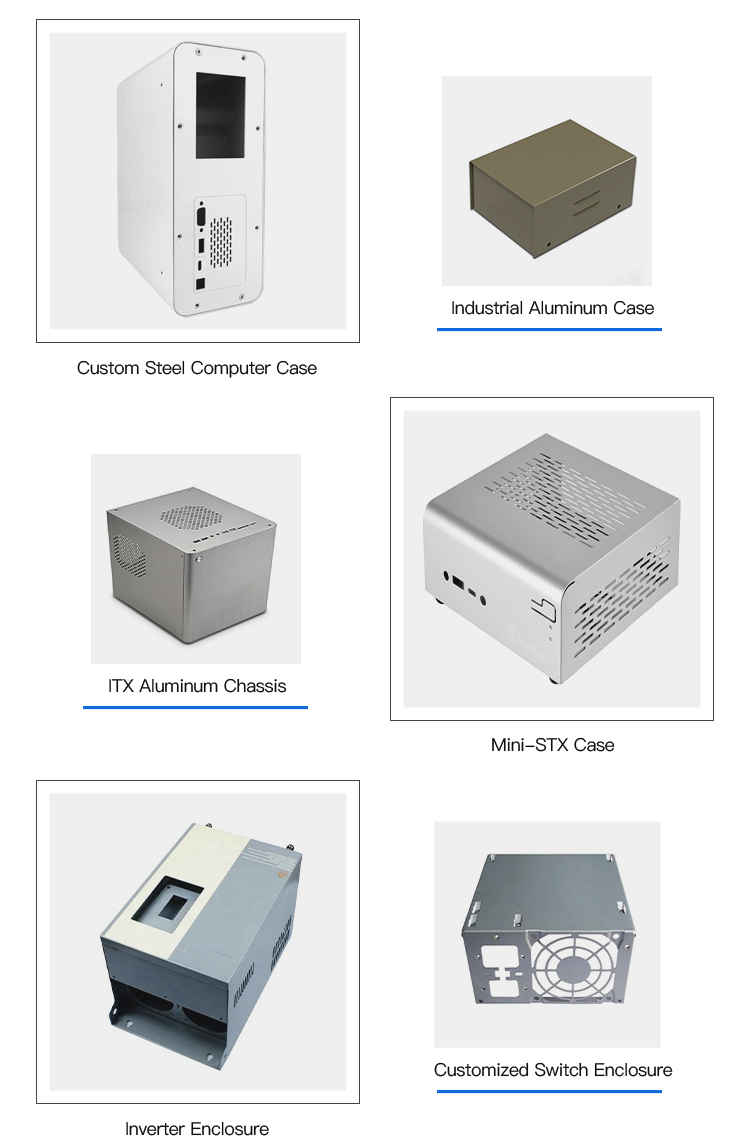

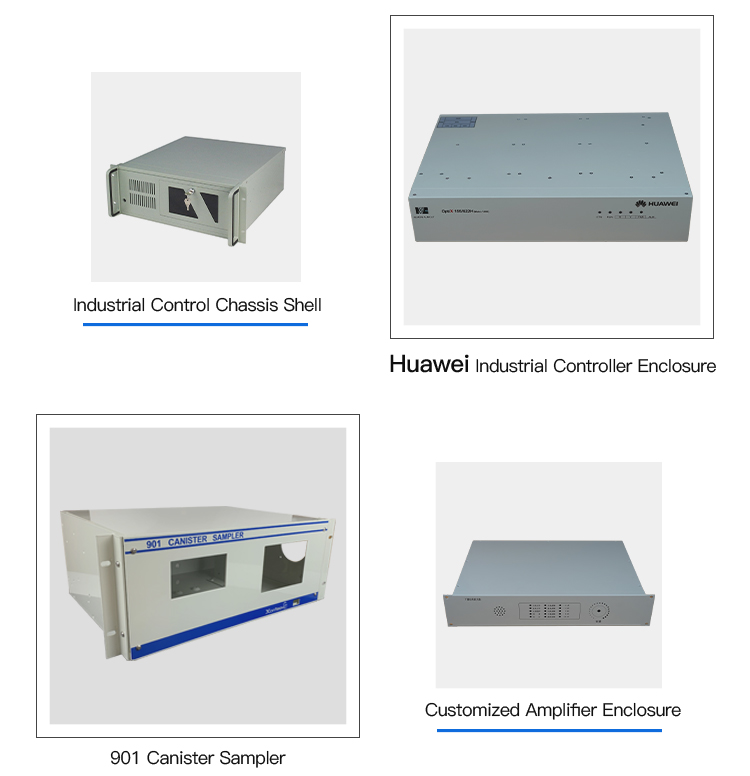

Our Bendig Parts have a wide range of applications, suitable for various scenarios, complete specifications, rich categories, and are widely used in various industries. Real shooting, the quality can be seen, every detail is strictly controlled, and the quality is more assured. Mature technology, better production quality.

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T, etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1, TA2/GR2, TA4/GR5, TC4, TC18, etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM, Acrylic, PC, etc. | |

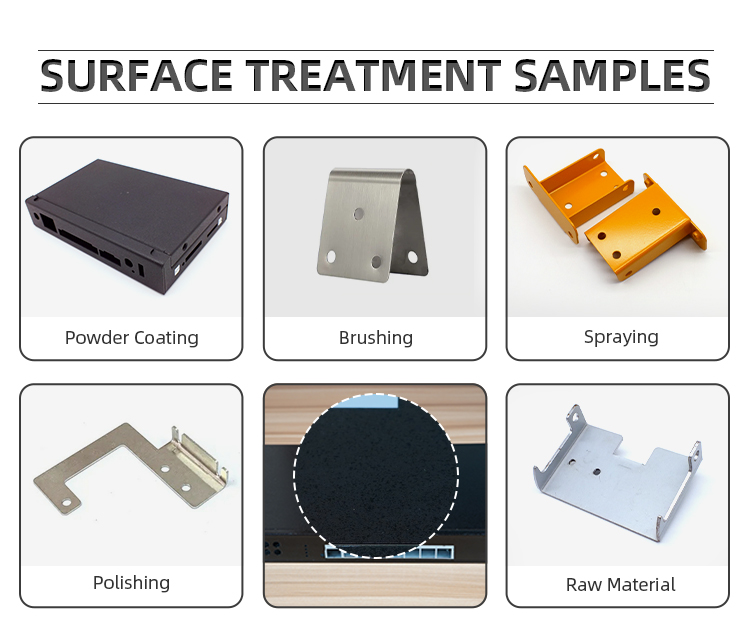

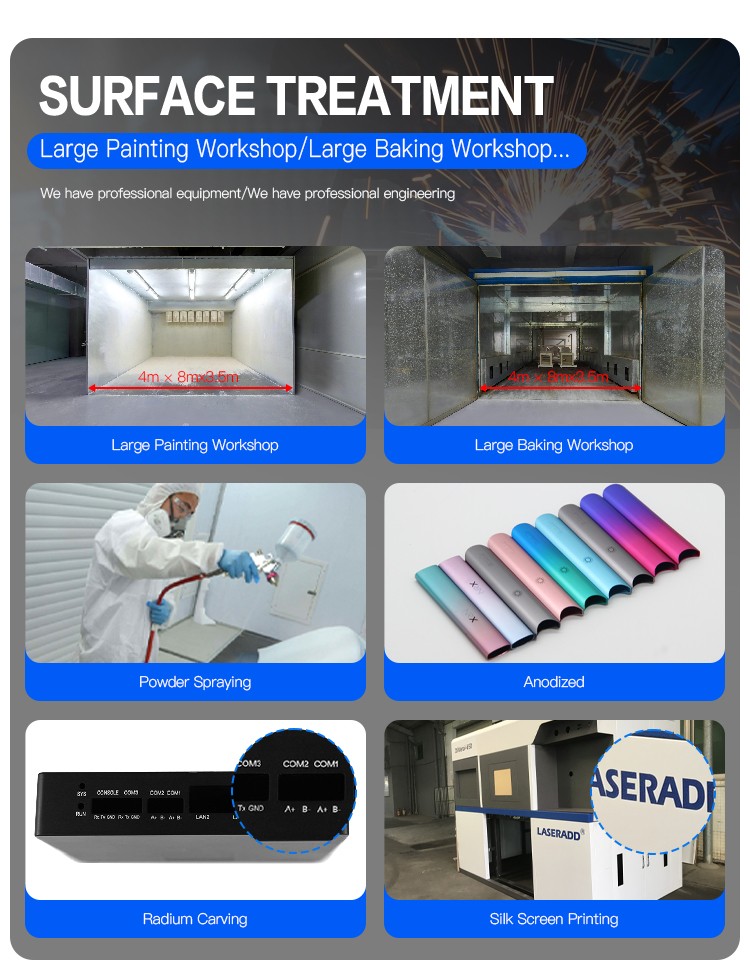

| Finish | Sandblasting, Anodized color, Blackening, Zinc/Nickl Plating, Polish, |

| Powder coating, Passivation PVD, Titanium Plating, Electro galvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing, Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling Machine, Laser Cutting Machine, etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

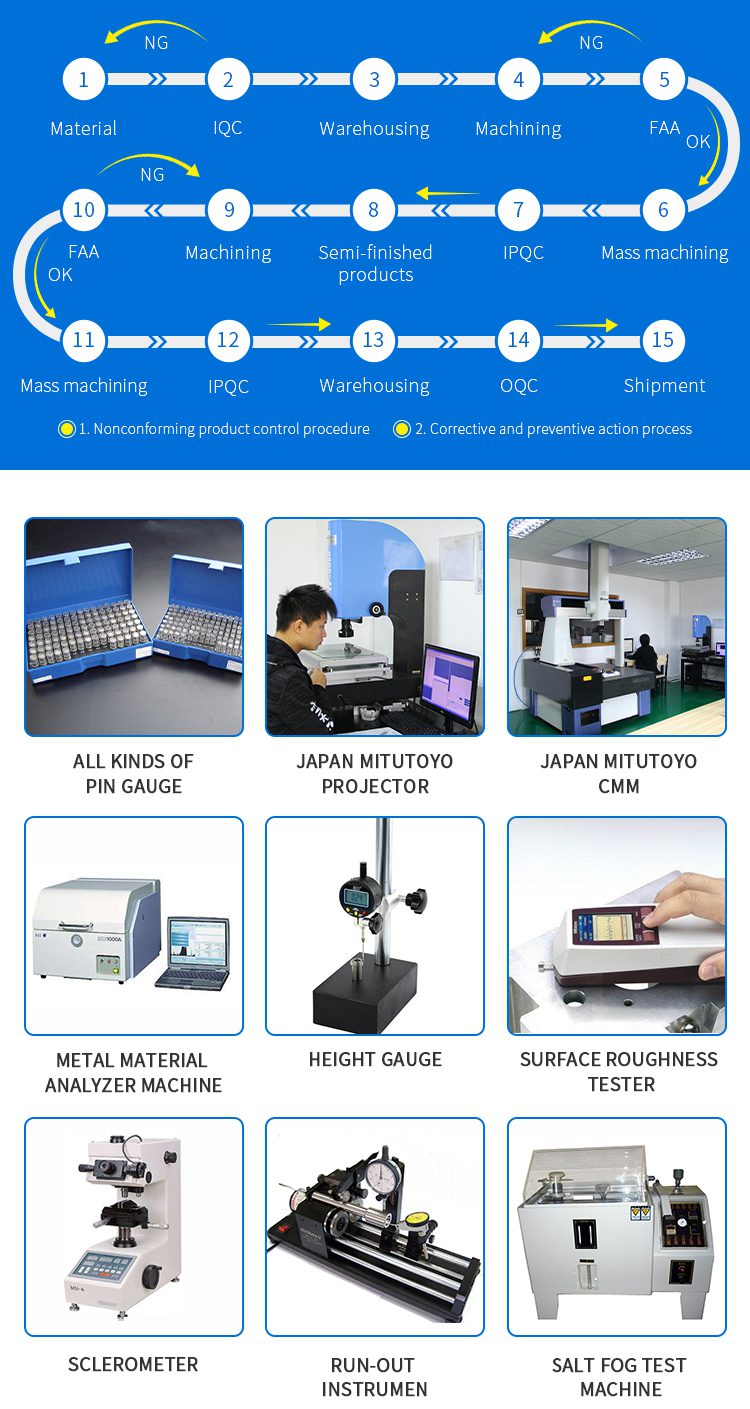

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier, CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |