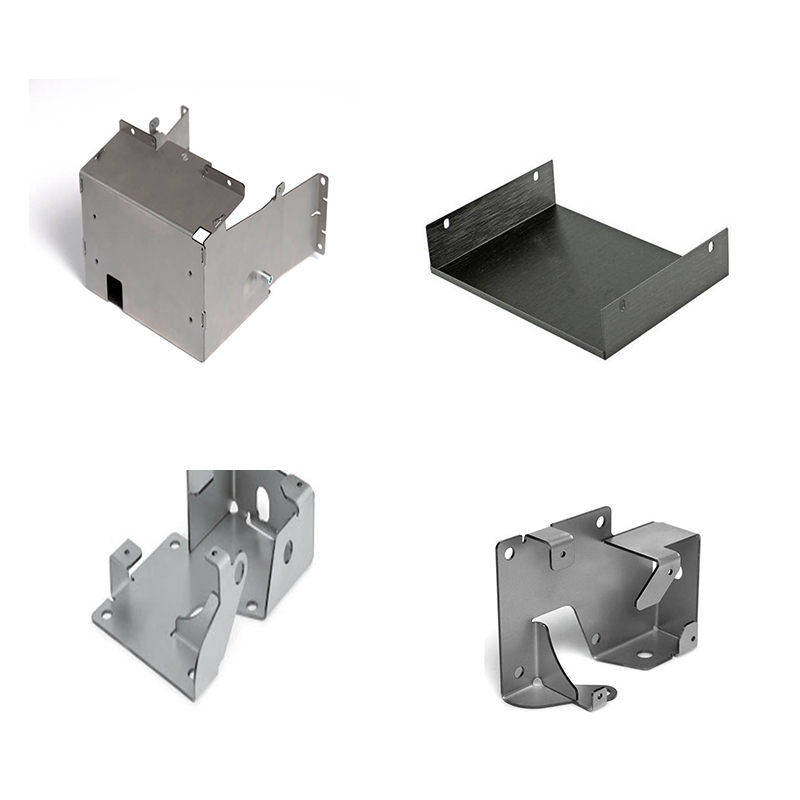

Sheet Metal Fabrication Bending Parts

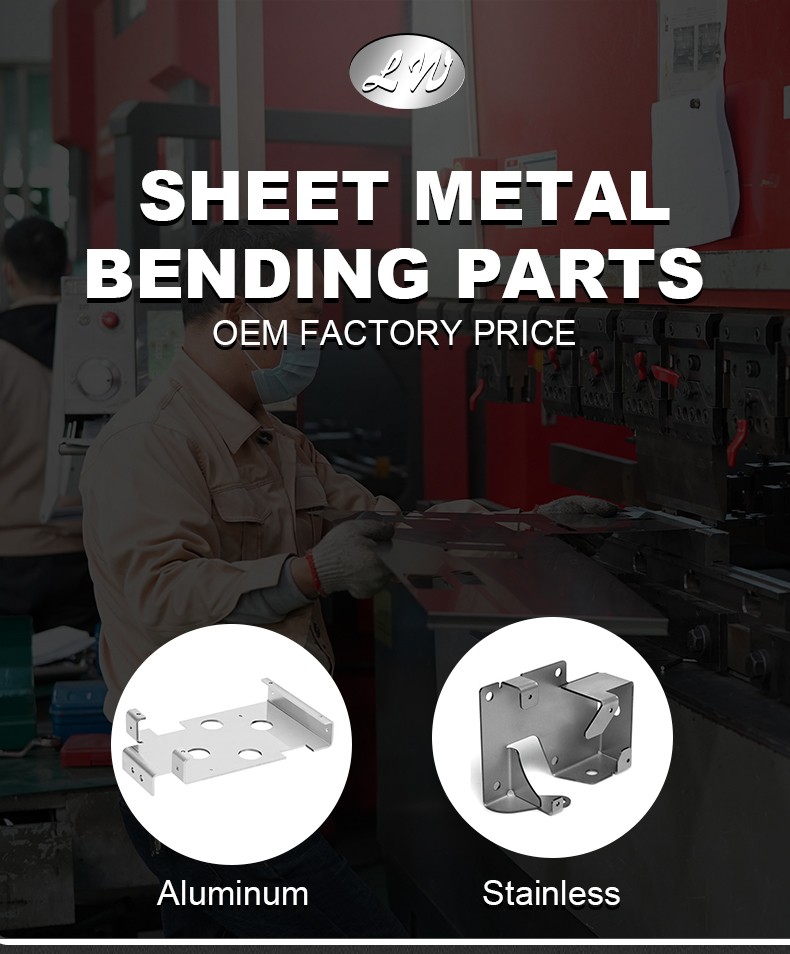

Bending thickness up to 8mm

Years of industry experience, focusing on non-standard precision structural parts sheet metal processing, large structural parts prototype processing

With no-mode production, sheet metal processing, rapid plate-making, small batch processing

LW precision OEM custom sheet metal bending aluminum parts stainless steel bending parts sheet metal fabrication service factory

We can provide high-quality metal fabrication service. Metal processing service refers to a series of processing techniques such as cutting, bending, stamping, welding and casting of metal materials, and processes raw materials into parts, components or finished products that meet customer needs. . We can cut processing, bending processing, stamping processing, welding processing, casting processing and metal processing services for a wide range of applications, including automobiles, machinery, electronics, aerospace, construction and other fields. Through metal processing services, precise processing and customized production of raw materials can be realized, the quality and performance of products can be improved, and production efficiency can also be improved and production costs can be reduced.

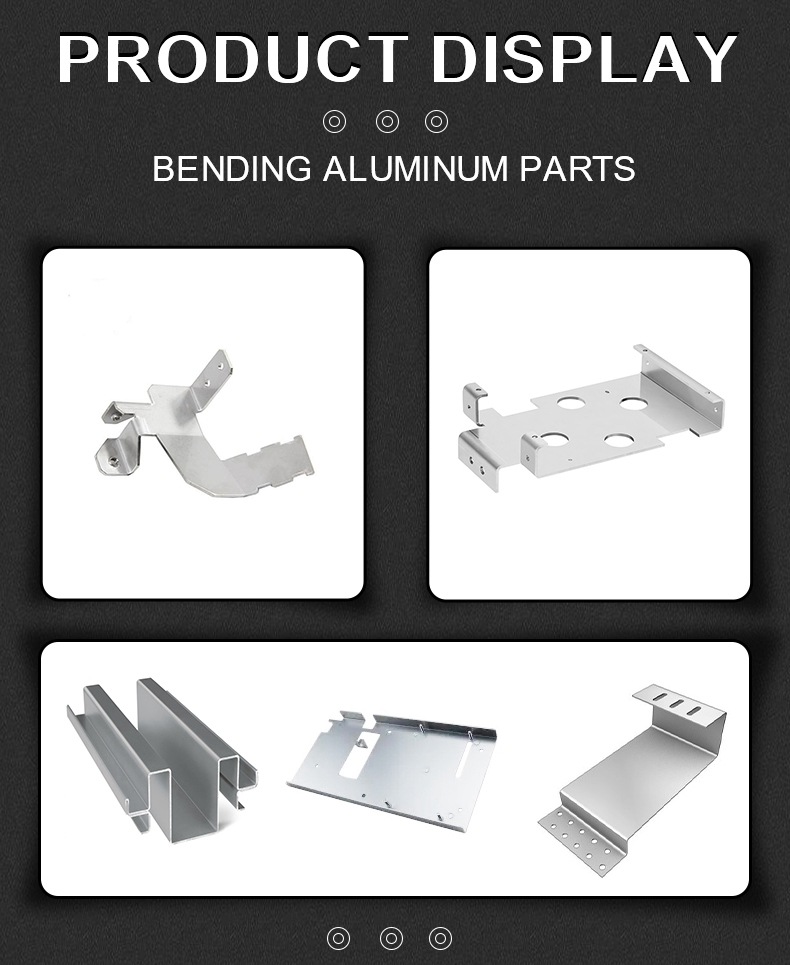

Bending aluminum is to bend aluminum plate or aluminum profile into the required shape through processing technology. Aluminum has good bending properties, so it is widely used in construction, automobile, aerospace and other fields. It should be noted that when performing bending processing, appropriate bending machines and molds should be selected, and the bending angle and bending radius should be strictly controlled to avoid cracks and deformation caused by excessive stretching and excessive bending. At the same time, appropriate processing speed and strength control should be carried out according to the thickness and hardness of the aluminum material to ensure the effect and quality of bending processing.

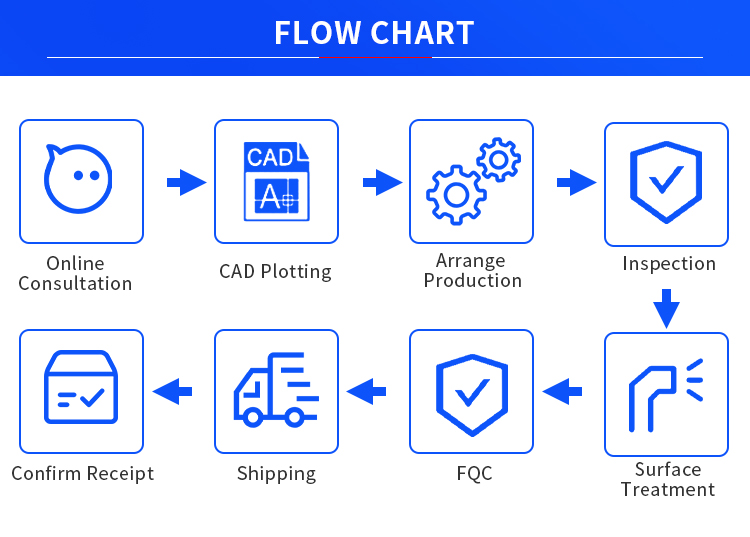

We can also make custom sheet metal. As long as you tell us the specifications you need, we can produce according to your requirements. You can also send us your design drawings. We will let our technicians do their best to create products that meet your needs. , for more details, please contact us.

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T, etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1, TA2/GR2, TA4/GR5, TC4, TC18, etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM, Acrylic, PC, etc. | |

| Finish | Sandblasting, Anodized color, Blackening, Zinc/Nickl Plating, Polish, |

| Powder coating, Passivation PVD, Titanium Plating, Electro galvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing, Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling Machine, Laser Cutting Machine, etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

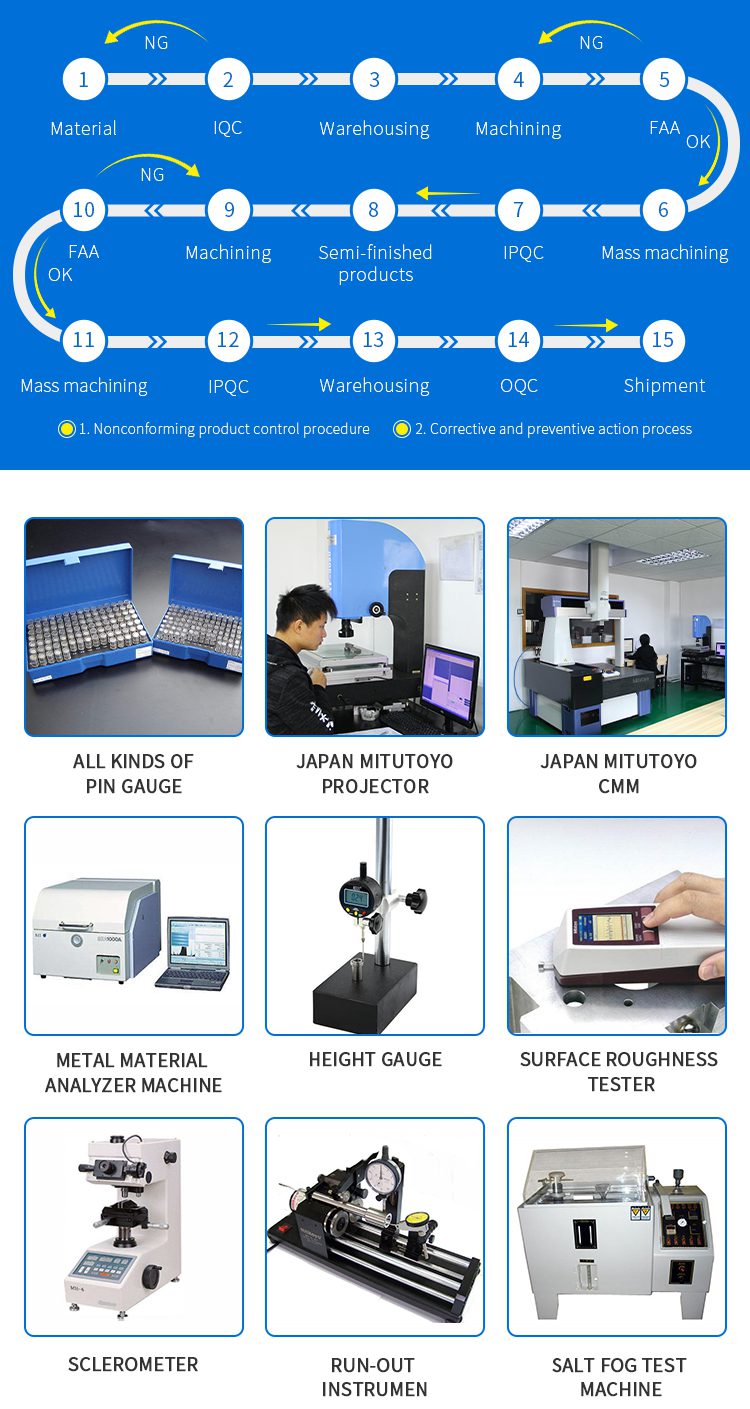

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier, CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |