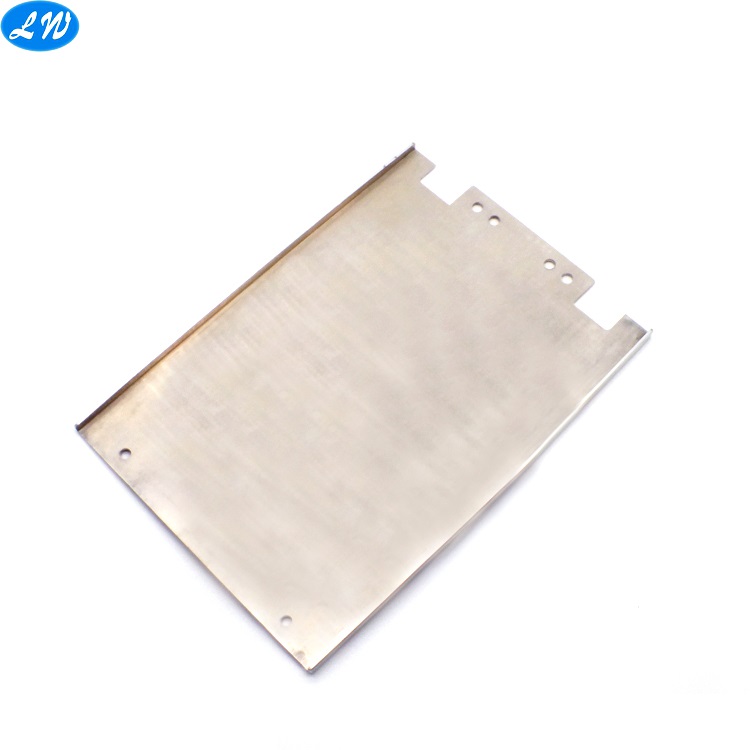

Hardware Accessories Metal Stamping Parts Processing

High precision metal stamping parts processing; (medium wire cutting processing, mechanical parts, mold parts, various non-standard parts)

According to the processing difficulty of metal stamping parts samples or drawings;

Various metals (copper, aluminum, 45# steel, casting, cr12 steel, SKD11)

We have a large inventory and fast shipping. We have a professional team that can help you out. We carefully select materials to ensure that the structure of each product is stable and strong, strictly select high-quality materials for production, and refuse to cut corners. There are many product types and specifications, which can support customization, with strong texture and gloss, and the overall brightness.

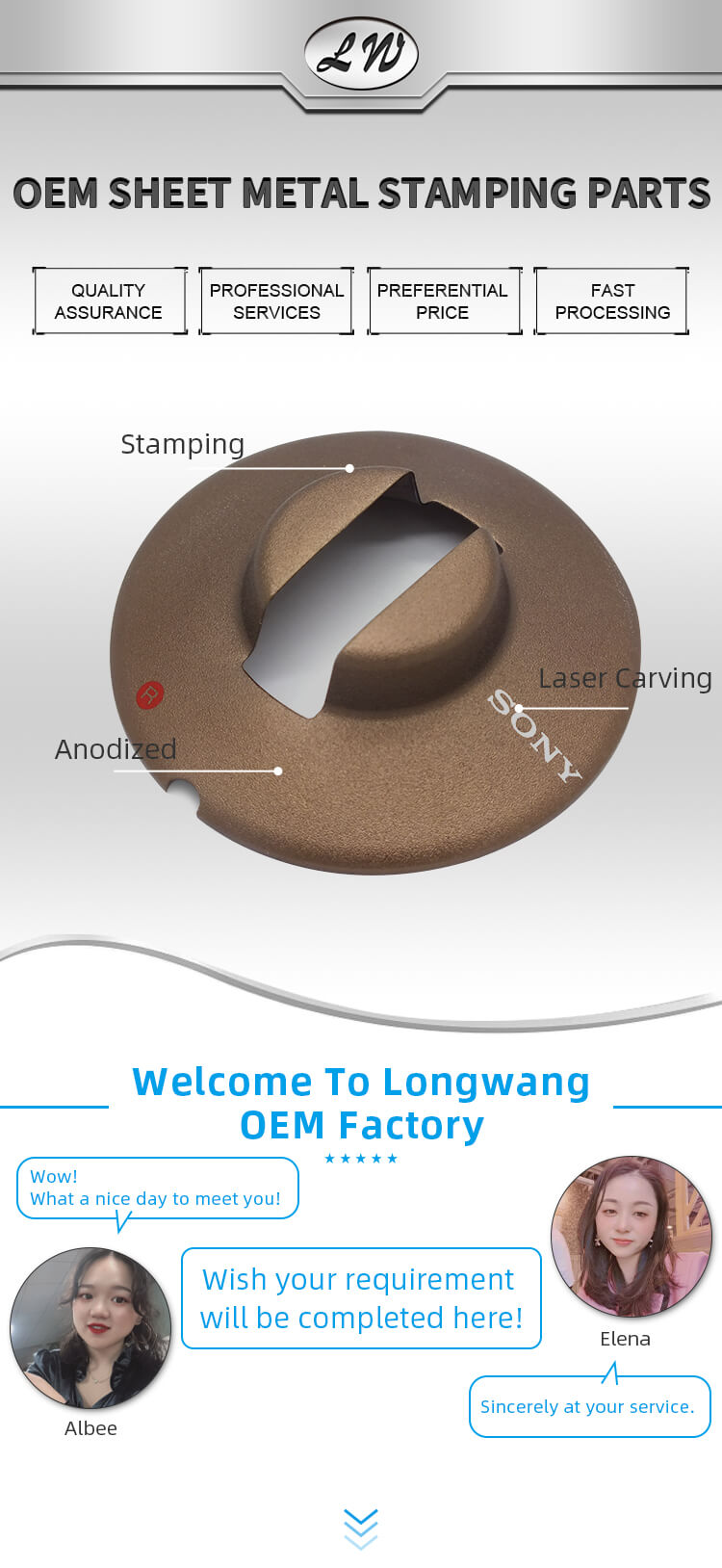

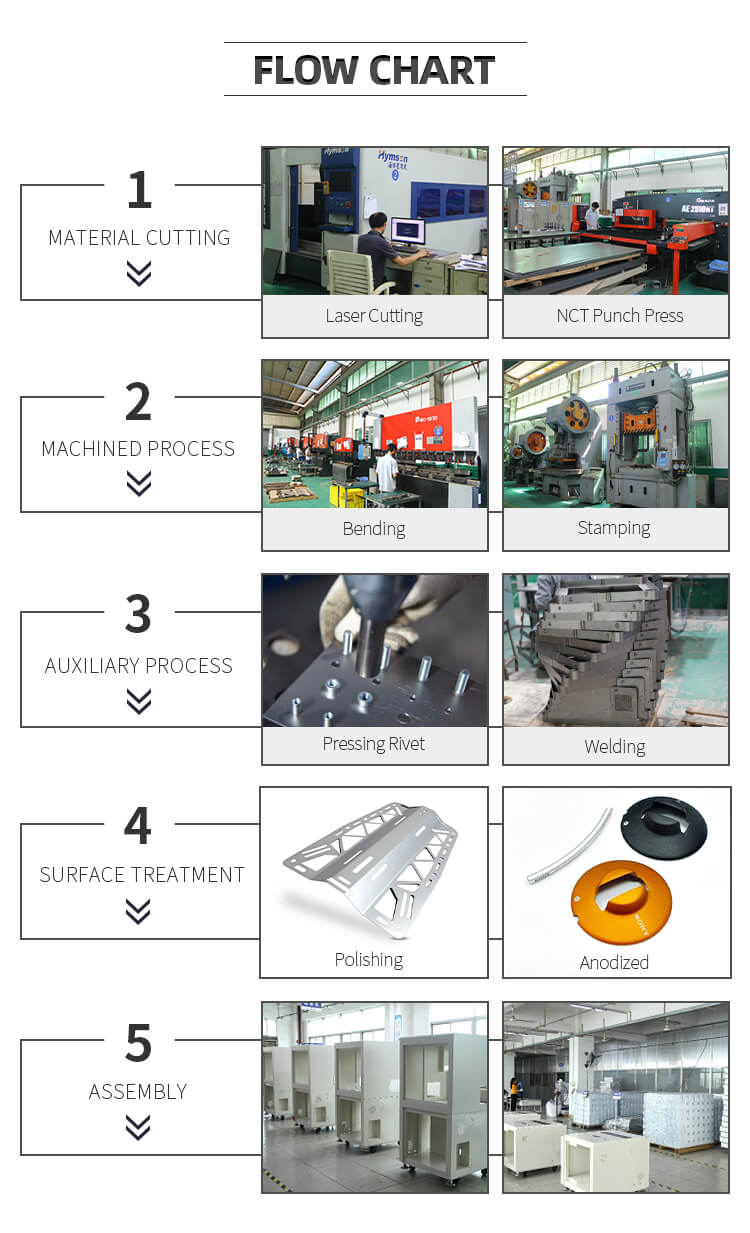

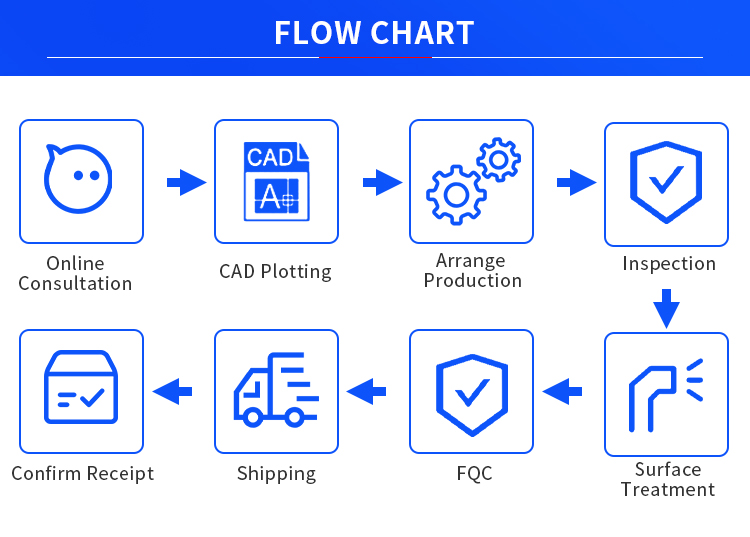

We have Sheet Metal Fabrication, which is a key technology that sheet metal technicians need to master, and an important process for forming sheet metal products. Sheet metal processing includes traditional cutting, blanking, bending and forming and other methods and process parameters, as well as various cold stamping die structures and process parameters, various equipment working principles and operating methods, as well as new stamping technology. and new technology. There are also Sheet Metal Enclosure and Sheet Metal Box for sale, you can go to our website to check or consult us.

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T, etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1, TA2/GR2, TA4/GR5, TC4, TC18, etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM, Acrylic, PC, etc. | |

| Finish | Sandblasting, Anodized color, Blackening, Zinc/Nickl Plating, Polish, |

| Powder coating, Passivation PVD, Titanium Plating, Electro galvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing, Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling Machine, Laser Cutting Machine, etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

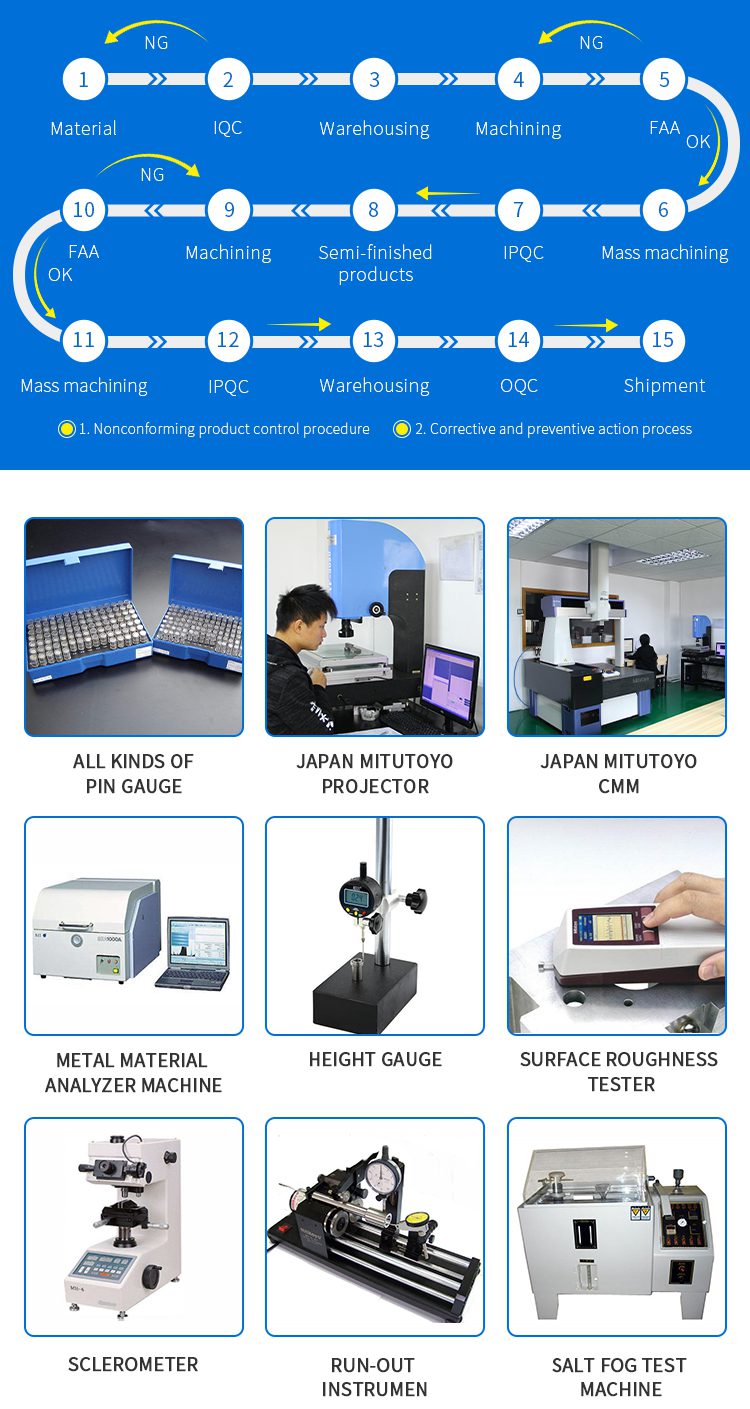

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier, CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |