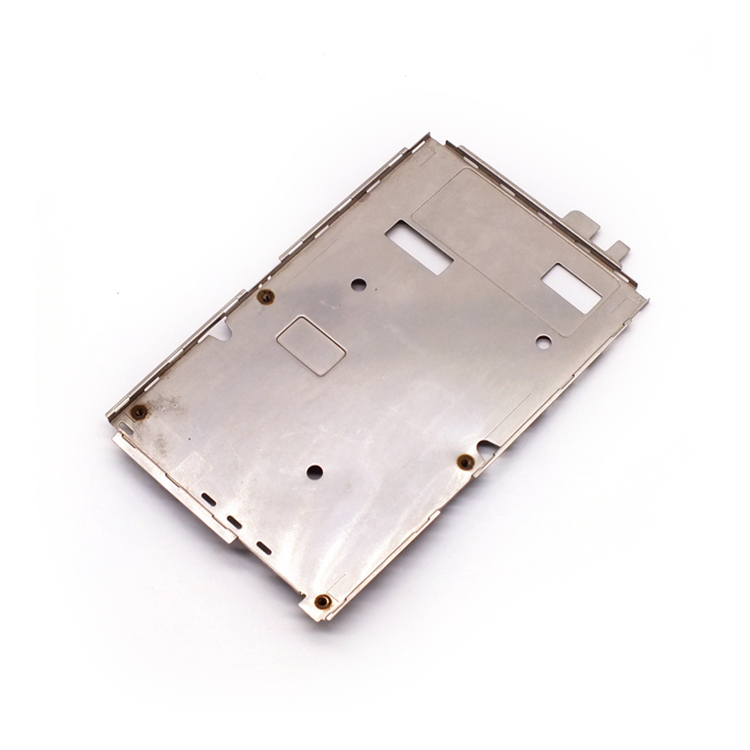

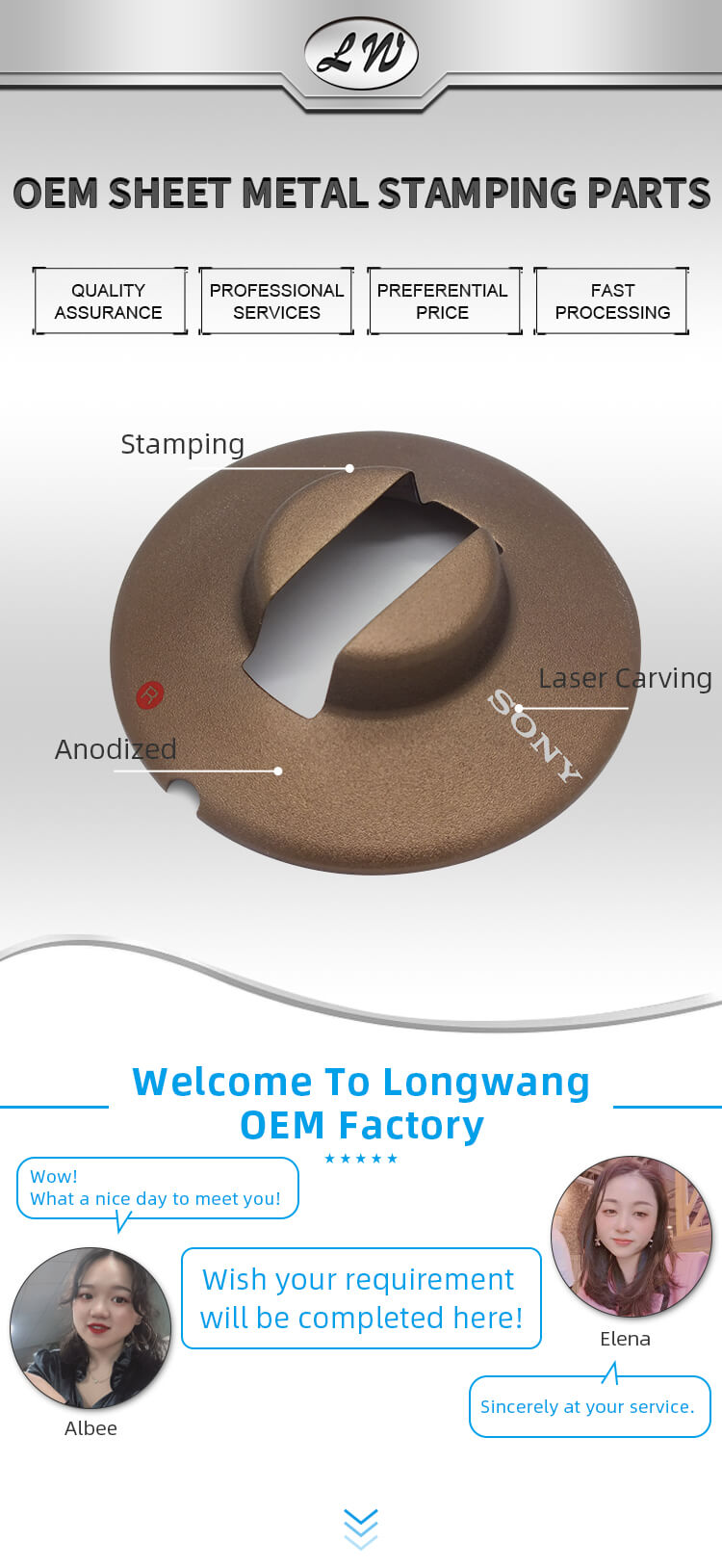

Sheet Metal Precison Stamping Parts

High precision metal stamping parts processing; (medium wire cutting processing, mechanical parts, mold parts, various non-standard parts)

According to the processing difficulty of metal stamping parts samples or drawings;

Various metals (copper, aluminum, 45# steel, casting, cr12 steel, SKD11)

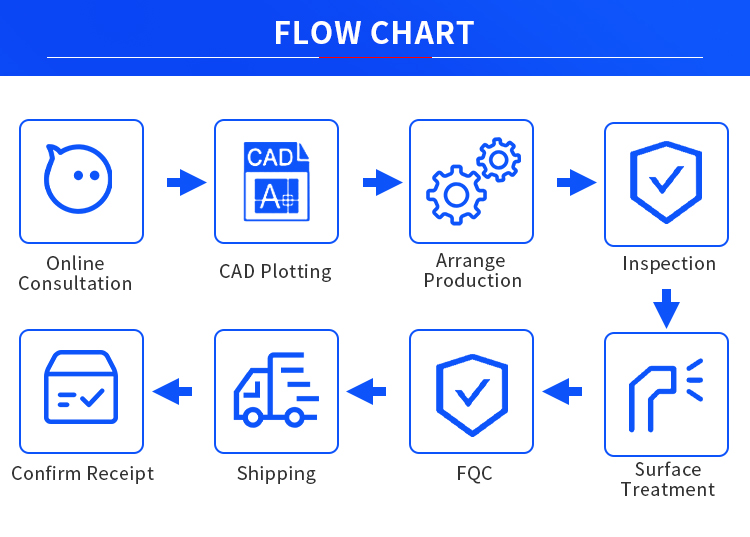

We have different Sheet Metal Fabrication parts on sale, Seiko quality, because of focus, so we understand non-standard sheet metal processing machine protective shells better, and we understand you better. For the manufacture of core technology, we have a professional R&D team, which has been recognized by many customers. Each product has been carefully developed, and the quality is guaranteed. You can buy it with confidence.

Some customized Stamping Parts, focus on precision processing, and make every product with heart. We have advanced CNC equipment with high precision. Raw materials are optimized, there is a quality department, high-precision and difficult hardware, and the physical factory provides you with a better service experience.

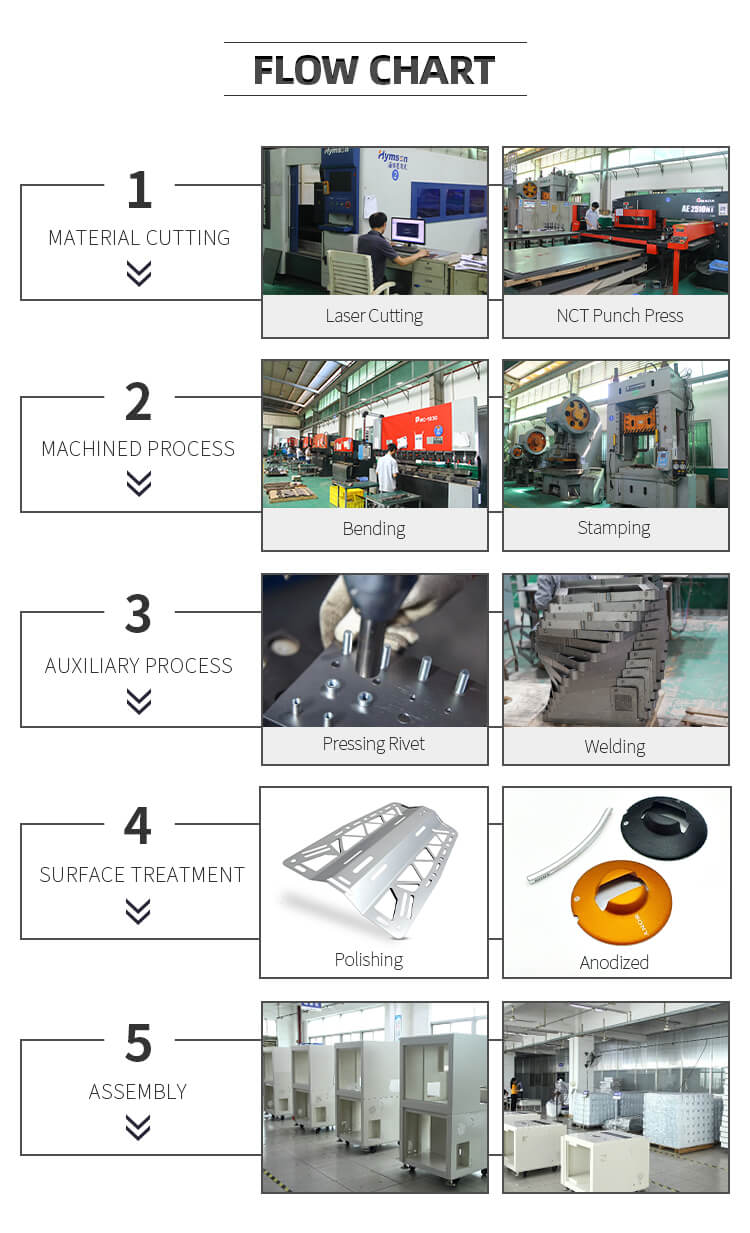

We also have Bending Parts for sale. We have many years of experience in the industry and focus on parts processing. We have a variety of processing techniques. For more details, please contact us. We are very happy to serve you.

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T, etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1, TA2/GR2, TA4/GR5, TC4, TC18, etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM, Acrylic, PC, etc. | |

| Finish | Sandblasting, Anodized color, Blackening, Zinc/Nickl Plating, Polish, |

| Powder coating, Passivation PVD, Titanium Plating, Electro galvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing, Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling Machine, Laser Cutting Machine, etc. | |

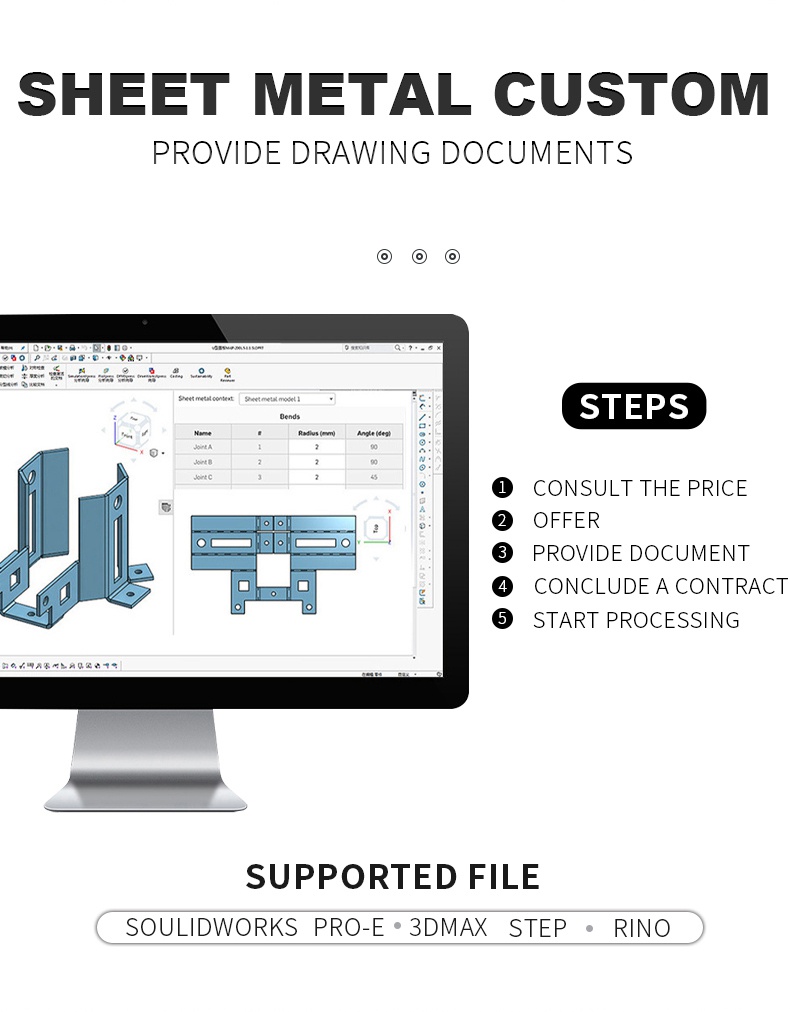

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

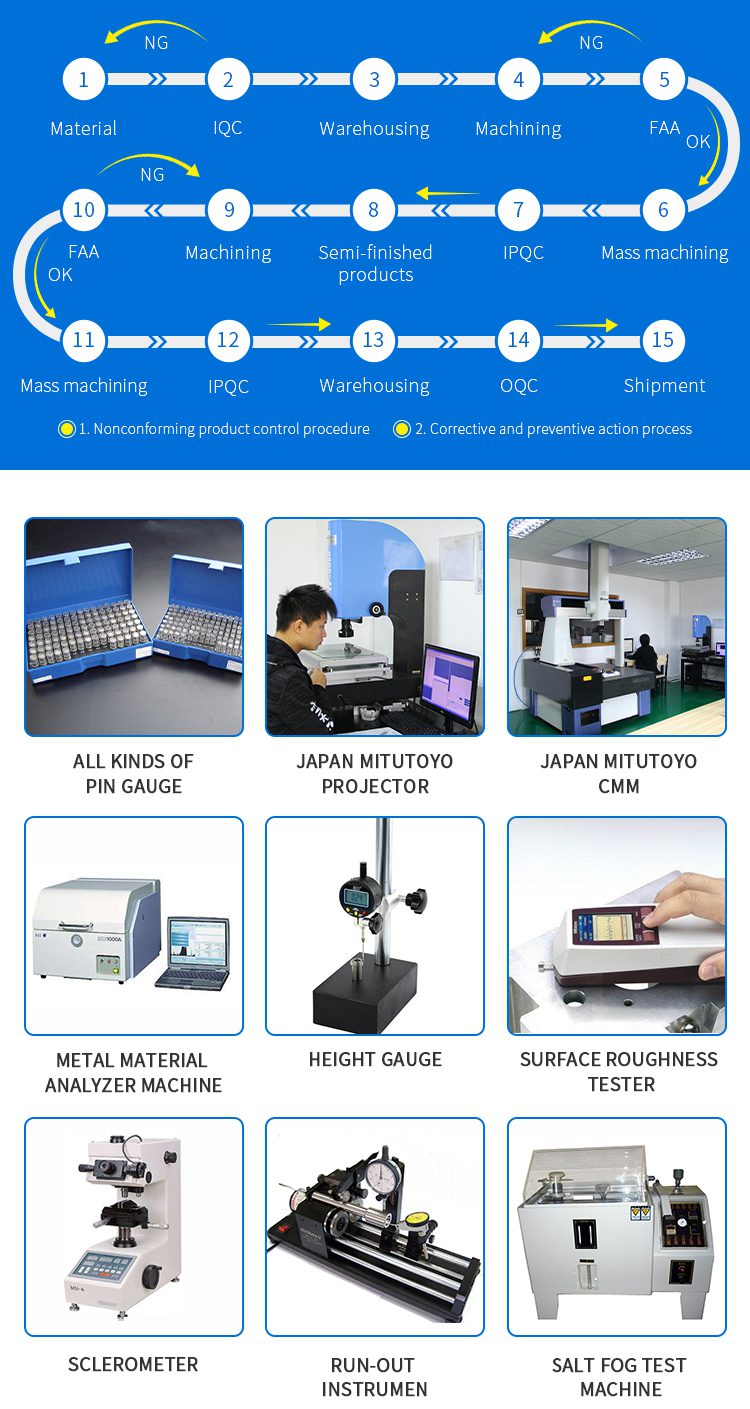

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier, CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |