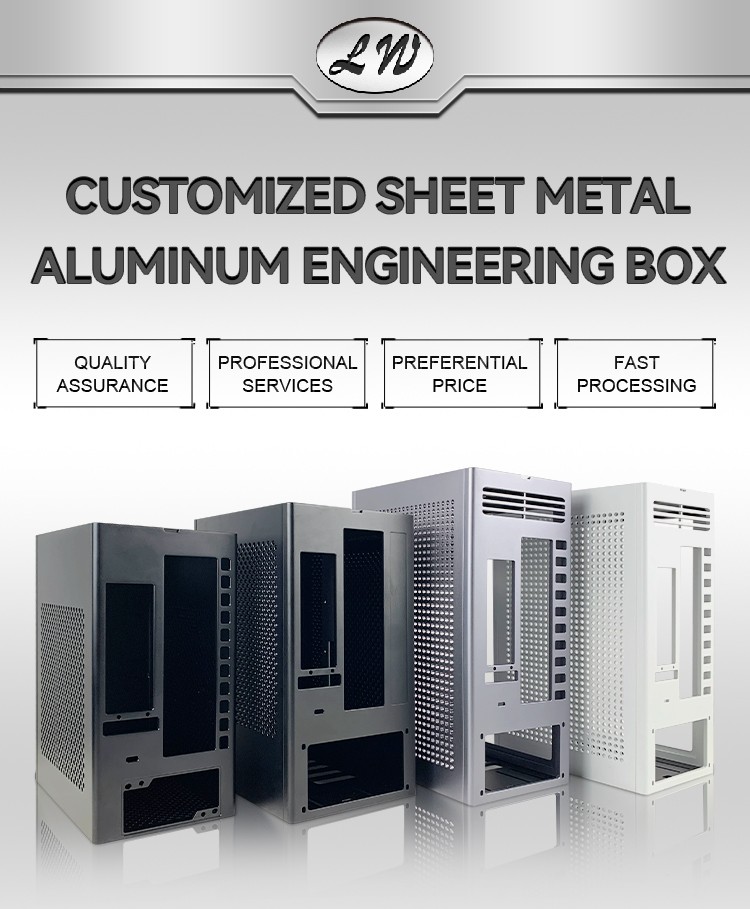

Sheet Metal Processing Mini Chassis Customization

Customized solutions for the entire industry chain from product material, design, production;

Focus on sheet metal chassis cabinet shell processing for 14 years.

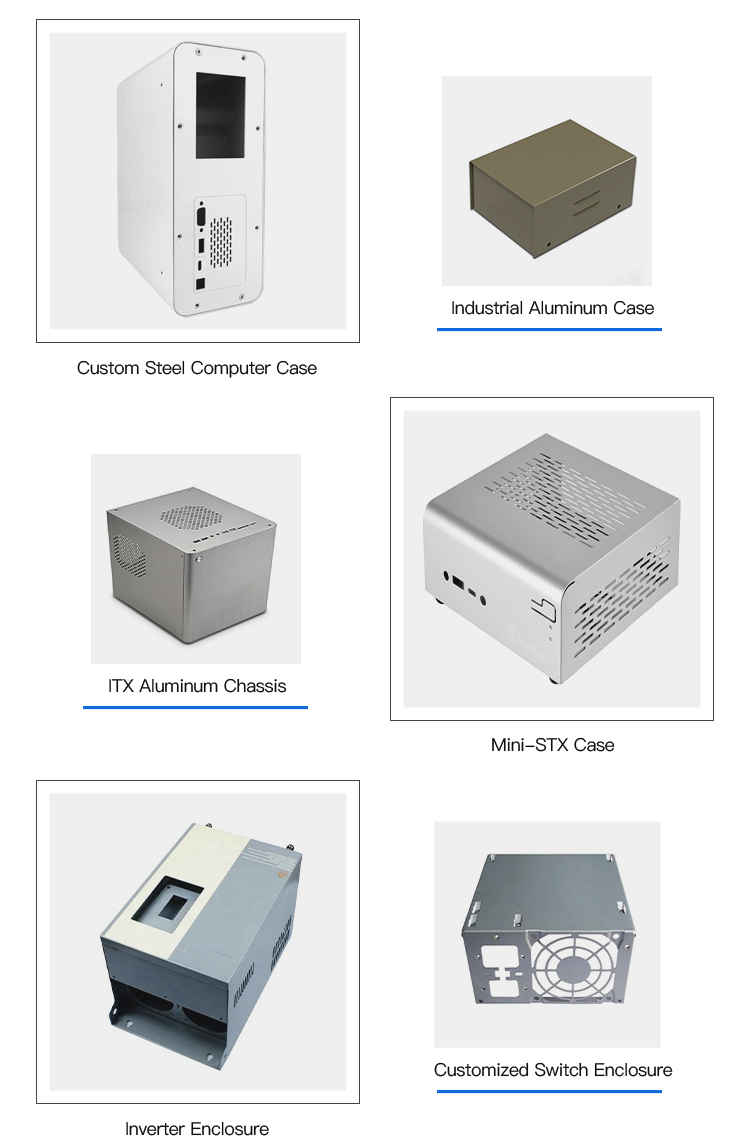

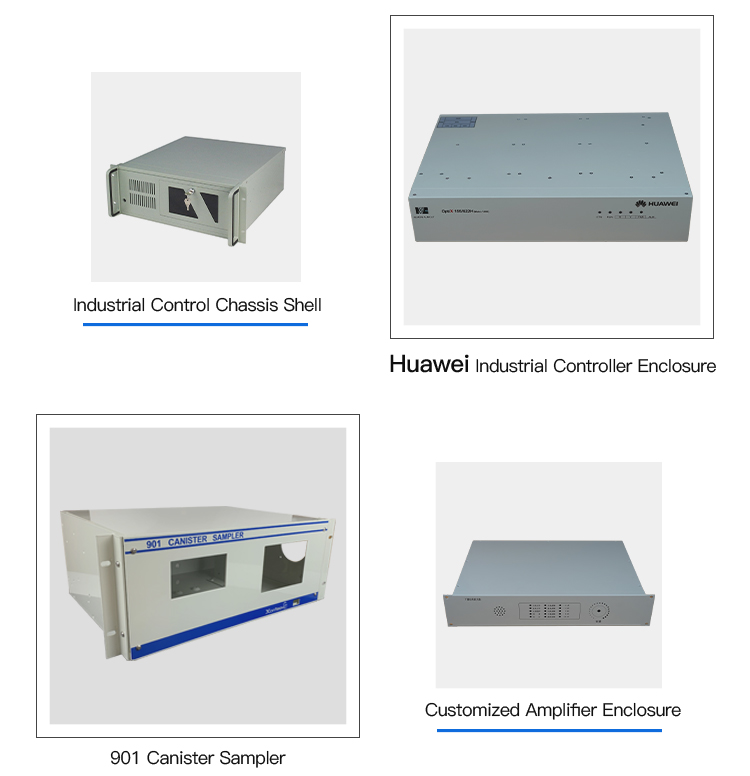

Since sheet metal processing and customization are semi-finished products, the price of each product is not accurately displayed to each customer. The product material specifications are basically customized according to customer requirements, so the price of finished products will be different. The products displayed are just a few samples, and the prices of some of them are listed above for your reference only. If you are interested in our products and have needs, please leave us a message, and we will give you a quotation as soon as possible. Provide you with reliable quality and reasonable price.

We have Sheet Metal Fabrication parts processing. Sheet metal, a processing technology, has not yet had a relatively complete definition of sheet metal. According to a definition in a foreign professional journal, it can be defined as: Sheet metal is a comprehensive cold working process for metal sheets (usually below 6mm), including shearing, punching/cutting/compounding, folding, riveting, splicing, Forming (such as car body), etc. Its remarkable feature is the same thickness of the same part. Among them, we also have processing Sheet Metal Cabine and Sheet Metal Enclosure for sale, welcome to consult.

Stamping Part is a forming processing method that applies external force to sheets, strips, pipes and profiles by means of presses and dies to cause plastic deformation or separation to obtain workpieces (stamping parts) of desired shape and size. Stamping and forging are both plastic processing (or pressure processing), collectively called forging. The stamped blanks are mainly hot-rolled and cold-rolled steel sheets and strips.

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T, etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1, TA2/GR2, TA4/GR5, TC4, TC18, etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM, Acrylic, PC, etc. | |

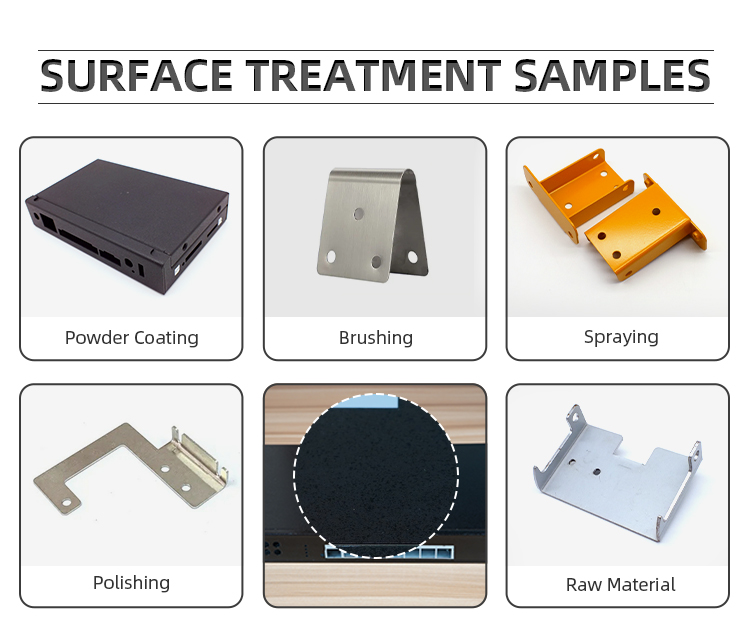

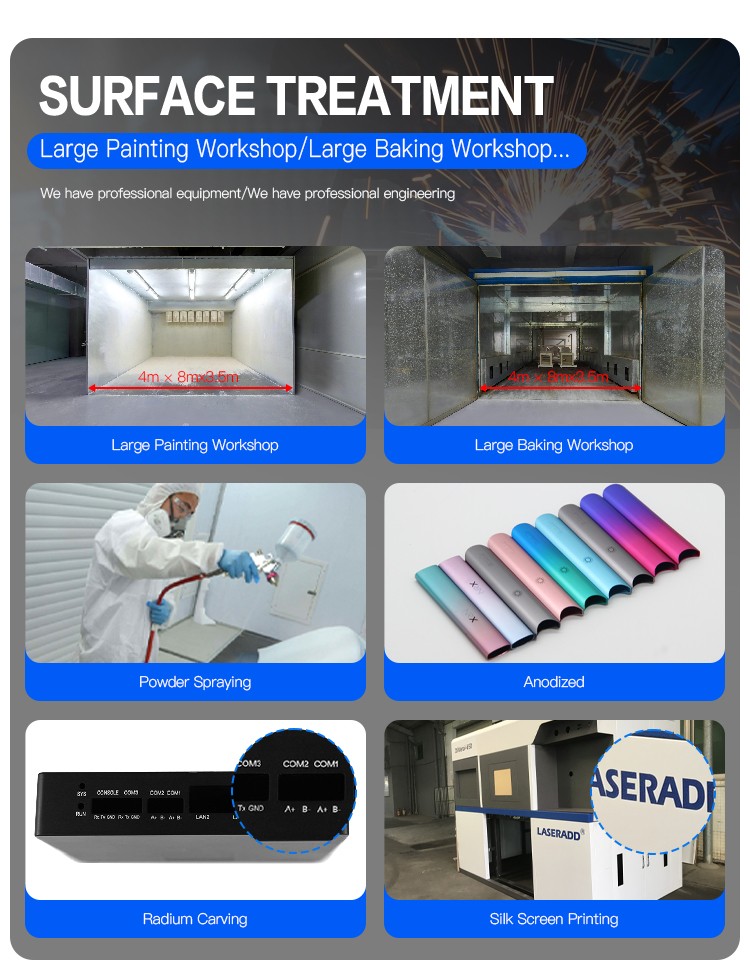

| Finish | Sandblasting, Anodized color, Blackening, Zinc/Nickl Plating, Polish, |

| Powder coating, Passivation PVD, Titanium Plating, Electro galvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing, Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling Machine, Laser Cutting Machine, etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

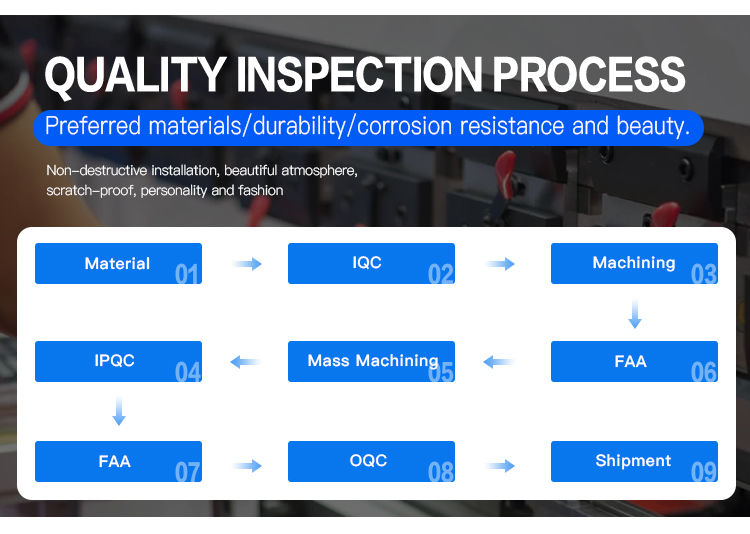

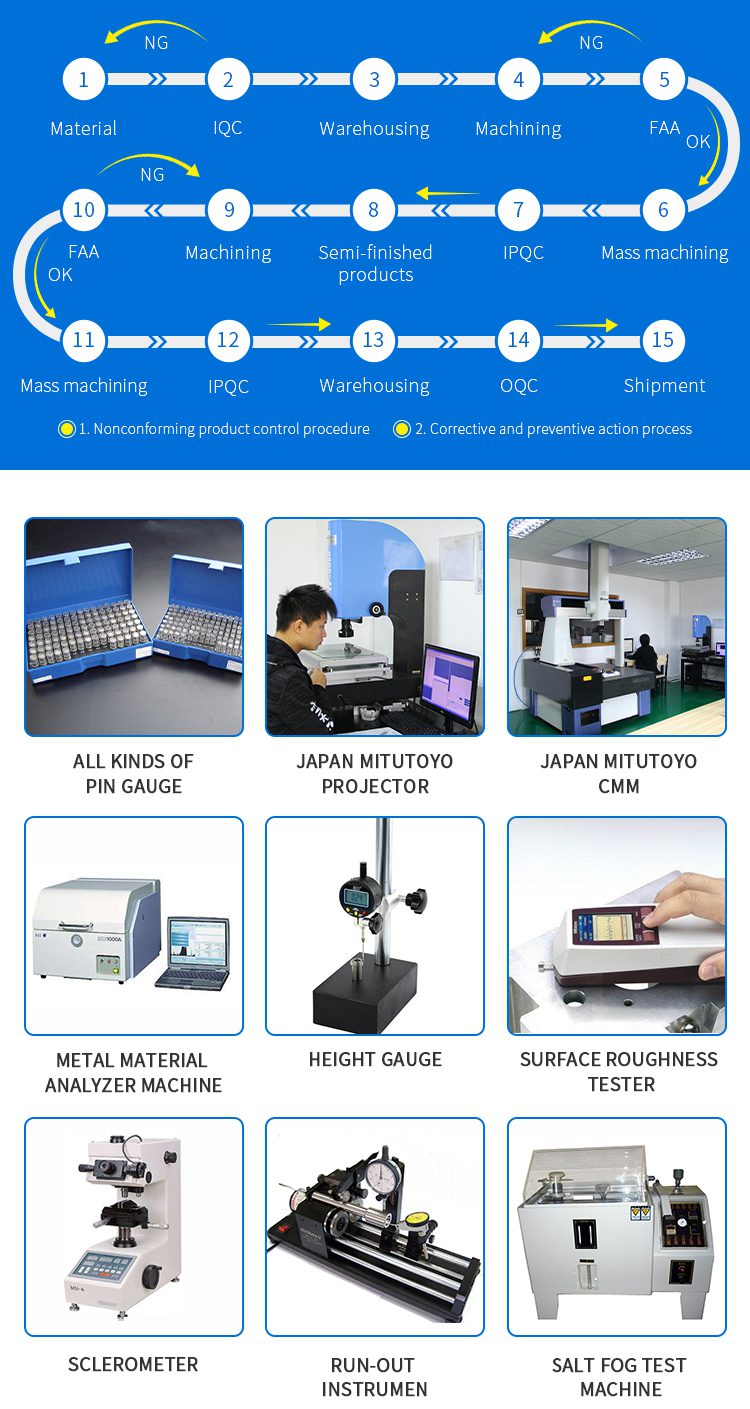

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier, CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |