Exploring the Differences Between 3-Axis Cnc Machines and 5-Axis Cnc Machines

CNC (Computer Numerical Control) machines have revolutionized manufacturing processes across industries, offering precision, efficiency, and automation. Among the various types of CNC machines available, 3-axis and 5-axis CNC machines stand out as two distinct categories with their own unique capabilities. In this article, we will delve into the key differences between these two types of CNC machines, highlighting their respective advantages and applications.

The Basics of CNC Machines

Before delving into the differences between 3-axis and 5-axis CNC machines, let's briefly review the fundamental concept of CNC machining. These machines are used to automate the production of parts and components, allowing for high precision and repeatability. CNC machines follow instructions from a computer program, guiding the movement of cutting tools to shape raw materials such as metal, plastic, or wood into the desired form.

Understanding 3-Axis CNC Machines

1. Movement in Three Directions: A 3-axis CNC machine operates in three primary directions: X-axis (left and right), Y-axis (front and back), and Z-axis (up and down). This means that the cutting tool can move along these three axes to perform cutting, milling, drilling, and shaping operations.

2. Limited Complex Geometry: While 3-axis machines are versatile and suitable for a wide range of applications, they are primarily designed for parts with relatively simple geometric shapes. They excel at 2D and 3D milling tasks but may struggle with intricate features or undercuts.

3. Cost-Effective: 3-axis CNC machines are generally more cost-effective and easier to maintain than their 5-axis counterparts. They are a popular choice for small to medium-sized businesses looking to improve their production processes.

Applications of 3-Axis CNC Machines:

- Prototyping and rapid manufacturing of simple parts

- Furniture production

- Sign and plaque making

- Flat sheet metal cutting and fabrication

- Engraving and wood carving

Understanding 5-Axis CNC Machines

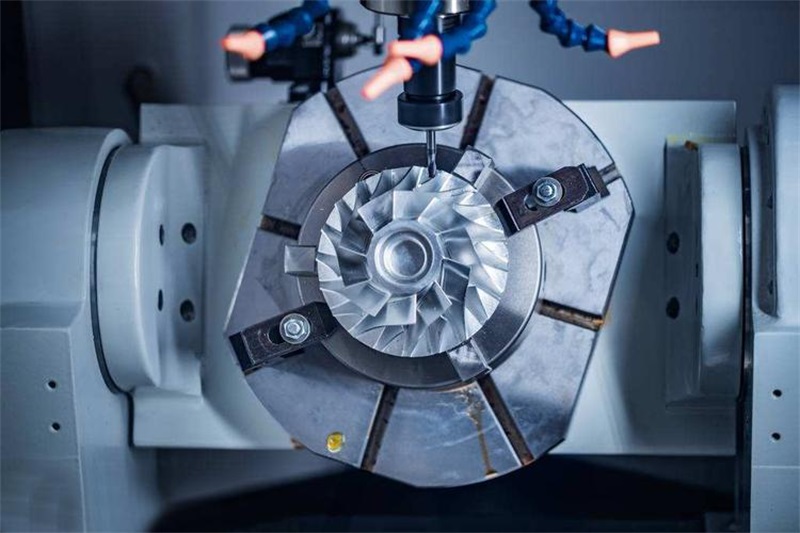

1. More Freedom of Movement: 5-axis CNC machines offer an extra level of flexibility by introducing two additional rotary axes, typically referred to as A and B axes. This allows the cutting tool to move in multiple directions, including tilting and rotating, in addition to the standard X, Y, and Z axes.

2. Complex Geometry: The ability to tilt and rotate the cutting tool makes 5-axis CNC machines ideal for machining complex parts with intricate features, undercuts, and contoured surfaces. They are often used for aerospace components, medical implants, and automotive parts.

3. Higher Precision: 5-axis machines can achieve higher precision and surface finish quality due to their ability to approach the workpiece from various angles. This reduces the need for multiple setups and secondary operations.

4. Increased Setup Complexity: Operating and programming 5-axis CNC machines can be more complex and require specialized training compared to 3-axis machines. The setup and alignment of the additional axes demand careful attention.

Applications of 5-Axis CNC Machines:

- Aerospace and aviation components

- Medical device manufacturing

- Automotive industry (for engine components)

- Complex mold making for the plastics industry

- Sculpture and art fabrication

In summary, 3-axis and 5-axis CNC machines cater to different manufacturing needs and requirements. While 3-axis machines are cost-effective and versatile for simpler parts, 5-axis machines offer unparalleled flexibility and precision, making them indispensable for complex and intricate components. When choosing between these two types of CNC machines, it's crucial to consider the specific applications and production demands of your project. Ultimately, both 3-axis and 5-axis CNC machines play vital roles in advancing the world of modern manufacturing.

Dongguan Longwang hardware Co.,Ltd own more than 200set CNC milling machining center to meet your different machining requirements. Contact us with your technical drawing, we can send our professional advice from CNC milling machining view.