10 Tips Told You How to Find a Good Machining Factory!

A CNC machining factory is a specialized manufacturing facility that focuses on the production of parts and components using Computer Numerical Control (CNC) technology. These factories are equipped with advanced CNC machines, computer-aided design (CAD) and computer-aided manufacturing (CAM) software, and skilled operators to efficiently and precisely produce a wide range of products for various industries. Let's take a closer look at the key aspects that define a typical CNC machining factory:

1.State-of-the-art Machinery: A CNC machining factory houses a variety of cutting-edge CNC machines, such as CNC milling machines, CNC lathes, CNC routers, and CNC laser cutters. These machines are capable of working with different materials, including metals, plastics, composites, and wood, allowing the factory to meet diverse manufacturing requirements.

2.Skilled Workforce: The factory employs a team of skilled and experienced CNC machine operators, programmers, and engineers. These professionals are well-versed in reading technical drawings, creating CNC programs, and ensuring that the machines operate at optimal levels to deliver high-quality products.

3.Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM): CAD software is used to create detailed digital models of the parts or components to be manufactured. CAM software then processes these models to generate the necessary G-code instructions that the CNC machines can follow. The integration of CAD and CAM streamlines the design-to-production workflow and enhances precision.

4.Prototyping and Customization: CNC machining factories often offer prototyping services, allowing clients to test and refine their designs before full-scale production. Additionally, these facilities can accommodate customization requests, tailoring parts to meet specific client requirements.

5.Quality Control Measures: Quality control is a critical aspect of CNC machining factories. Throughout the production process, rigorous inspections and tests are conducted to ensure that the finished products adhere to the required specifications and tolerances. This ensures that the final output is of consistent high quality.

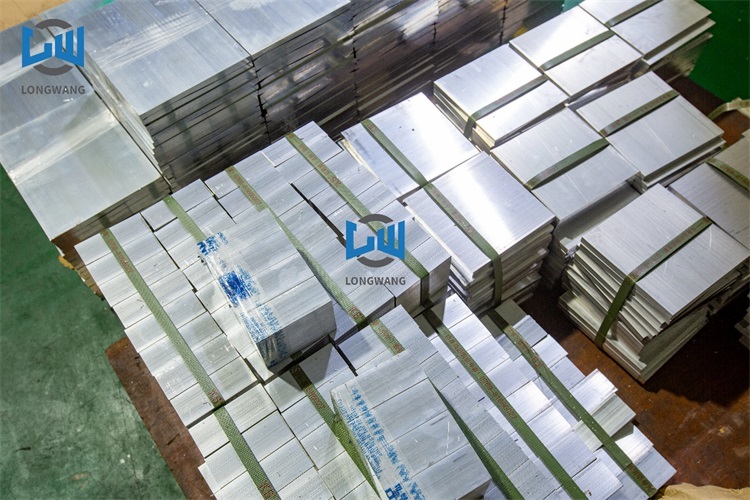

6.Material Handling and Storage: CNC machining factories have designated areas for material storage to maintain a well-organized inventory. Material handling processes are carefully managed to minimize waste and ensure efficient usage.

7.Capacity for Mass Production: CNC machining factories are well-suited for mass production due to the automation and precision offered by CNC technology. This capability allows for efficient and cost-effective manufacturing of large quantities of parts with consistent quality.

8.Integration of Secondary Processes: In addition to CNC machining, some factories may offer secondary processes such as finishing, coating, assembly, and packaging. This provides clients with comprehensive manufacturing solutions.

9.Safety and Environmental Considerations: A reputable CNC machining factory prioritizes the safety of its workers and the environment. Adequate safety measures are implemented, and waste disposal practices adhere to relevant regulations to minimize the environmental impact.

10.Continuous Improvement: As technology evolves, CNC machining factories strive to stay at the forefront of innovation. They invest in research and development to adopt the latest advancements in CNC technology and manufacturing techniques, ensuring they remain competitive and meet the evolving needs of their clients.

In summary, a CNC machining factory is a sophisticated and efficient production facility that leverages CNC technology, skilled personnel, and quality control measures to manufacture precise and intricate parts and components for a diverse range of industries.

Dongguan Longwang Hardware Co., Ltd. has been in the field of CNC processing for 15 years. It has experience in processing parts in various industries such as medical, automobile and motorcycle parts, automation equipment, and new energy. The engineering team can provide drawing optimization and cost optimization in the early stage to achieve a win-win situation. If you have any parts need machining and quote, please contact us freely!