Shell Machining Design Keyboard Machining CNC Machining

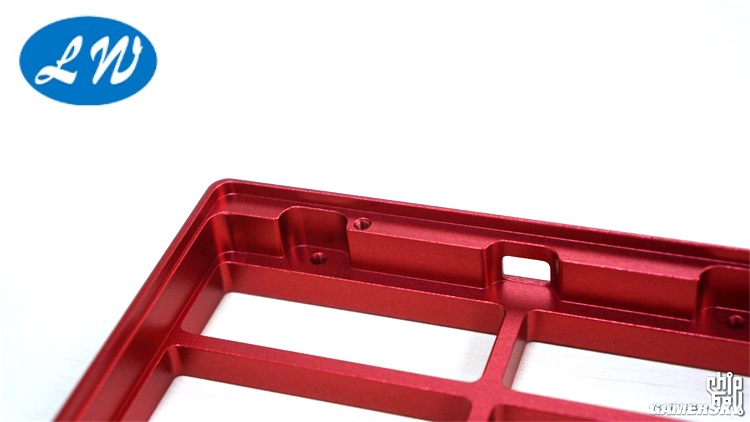

Customized CNC machining aluminum game keyboard kit;

Machined based on your own design and logo;

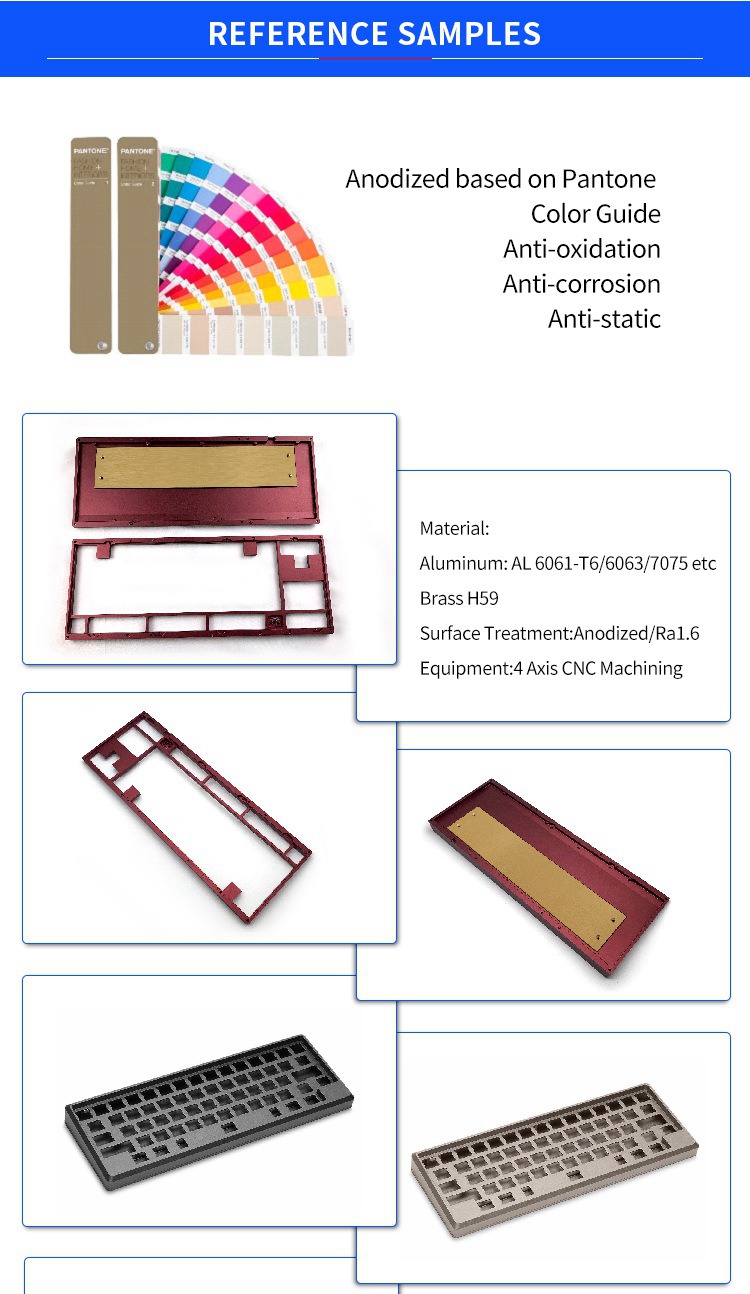

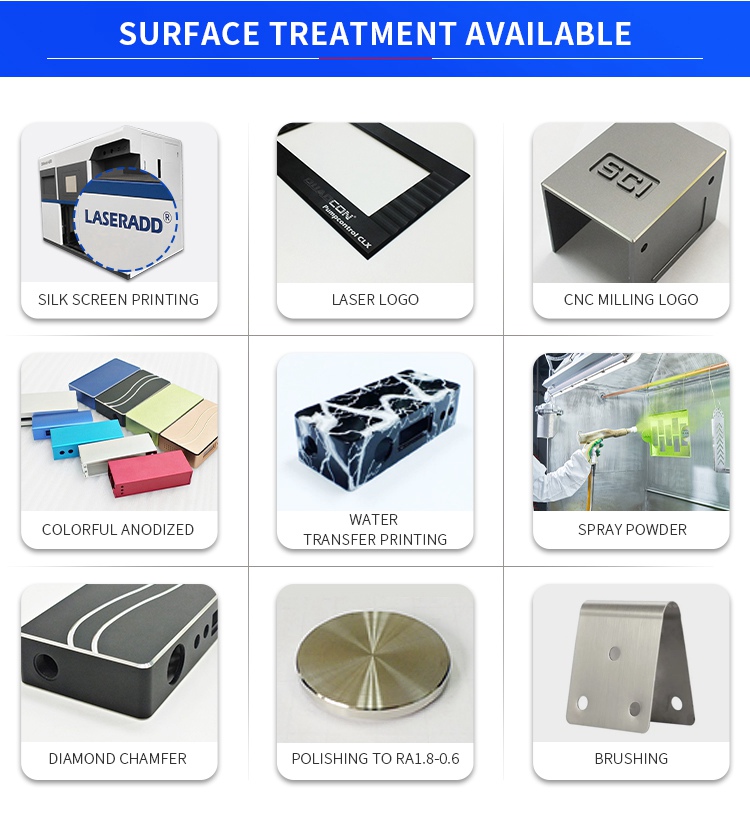

Different surface treatment for your different color requirement;

Color based on Pantone Color Guide;

Material is the same quantity standard with iphone's.

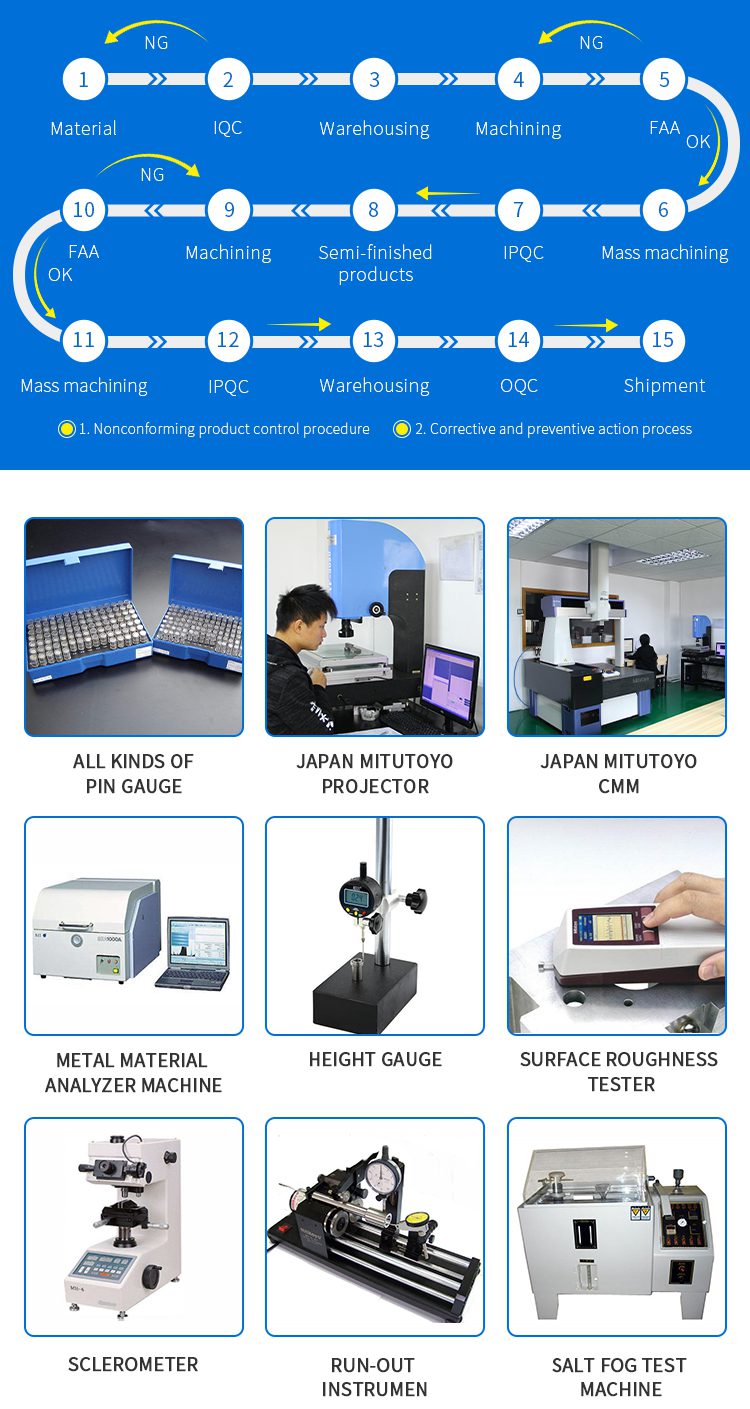

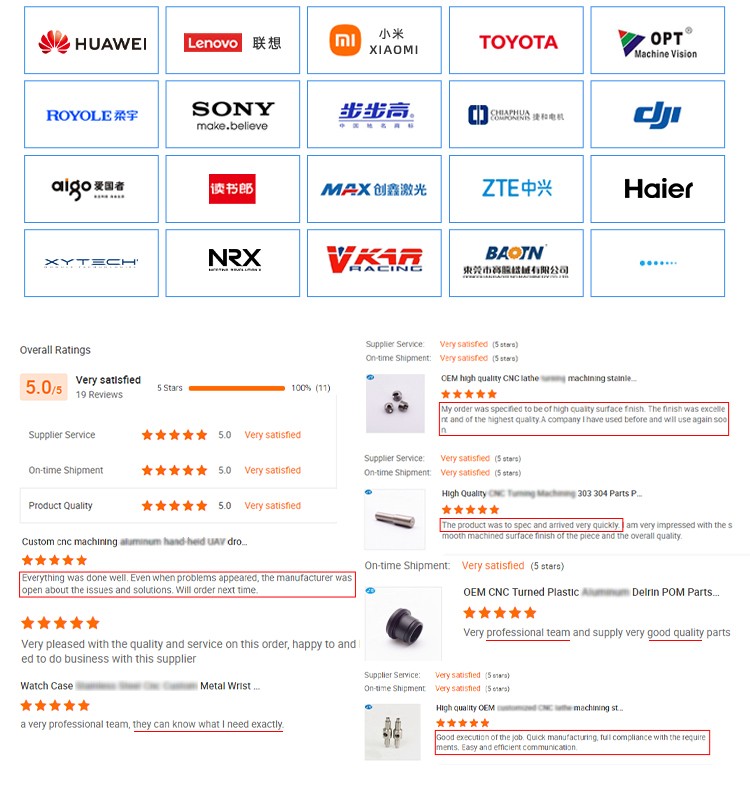

We have CNC Aluminum Keyboard Cases of different materials on sale, with complete production equipment, strong overall strength, and a complete and scientific quality management system. We are a professional manufacturer of hardware spare parts and finished product assembly. We focus on providing hardware mold manufacturing, aluminum alloy die castings.

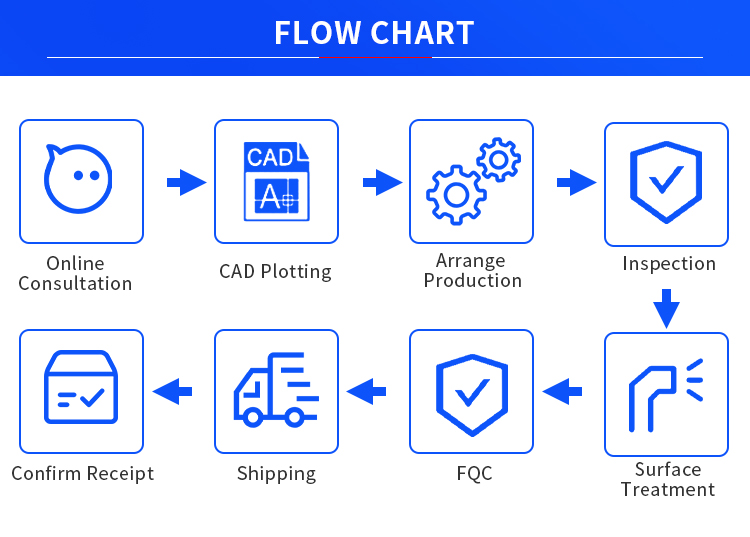

If you need a different CNC Keyboard Design, we are an honest merchant with reliable quality, good quality and fast delivery. We also integrate a series of production processes such as design, manufacturing, molding and assembly. If you need processing and customization, we can customize the production according to the customer's requirements and try our best to meet the needs of customers.

We can complete according to customer requirements, fast delivery, reasonable price, welcome new and old customers to visit and guide. Support the production of Aluminum Keyboard Case. Our products are of good quality and precision, and our factory has complete processing equipment.

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T, etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1, TA2/GR2, TA4/GR5, TC4, TC18, etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM, Acrylic, PC, etc. | |

| Finish | Sandblasting, Anodized color, Blackening, Zinc/Nickl Plating, Polish, |

| Powder coating, Passivation PVD, Titanium Plating, Electro galvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing, Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling Machine, Laser Cutting Machine, etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier, CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |