Cnc Machining Of Computer Keyboard Shell

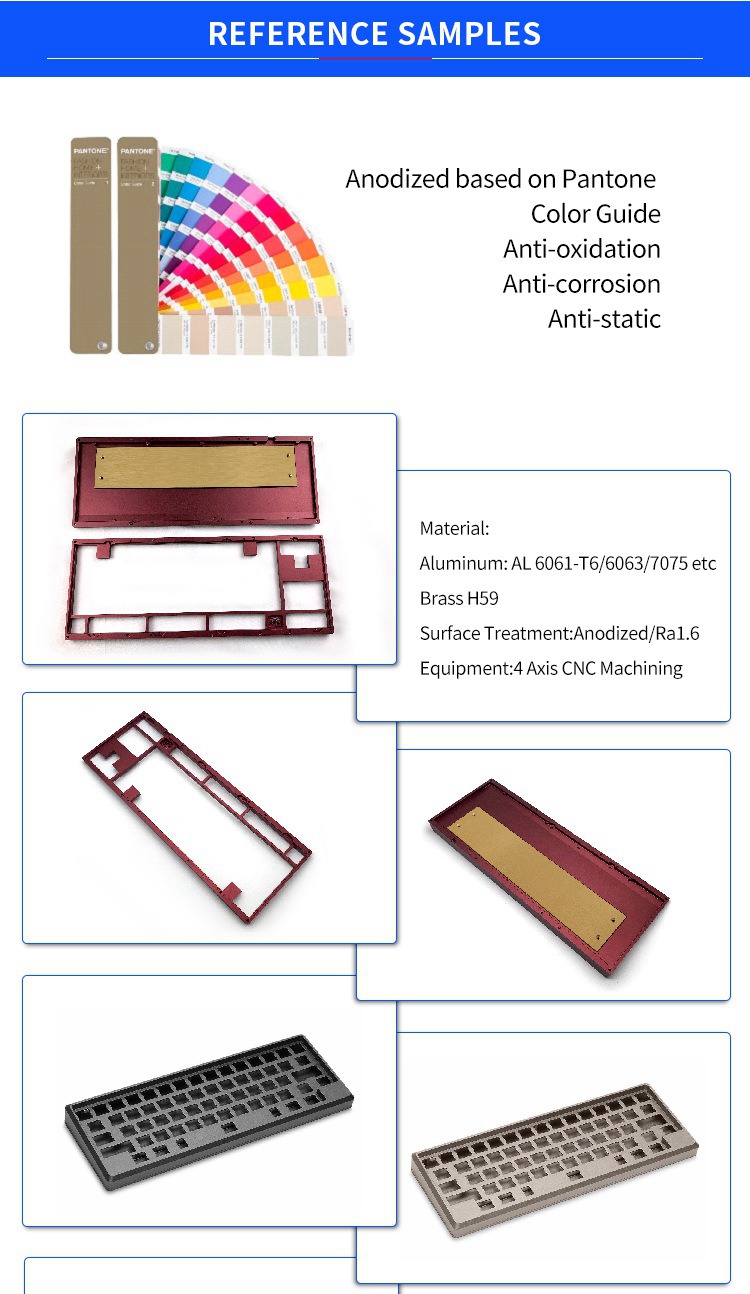

Customized CNC machining aluminum game keyboard kit;

Machined based on your own design and logo;

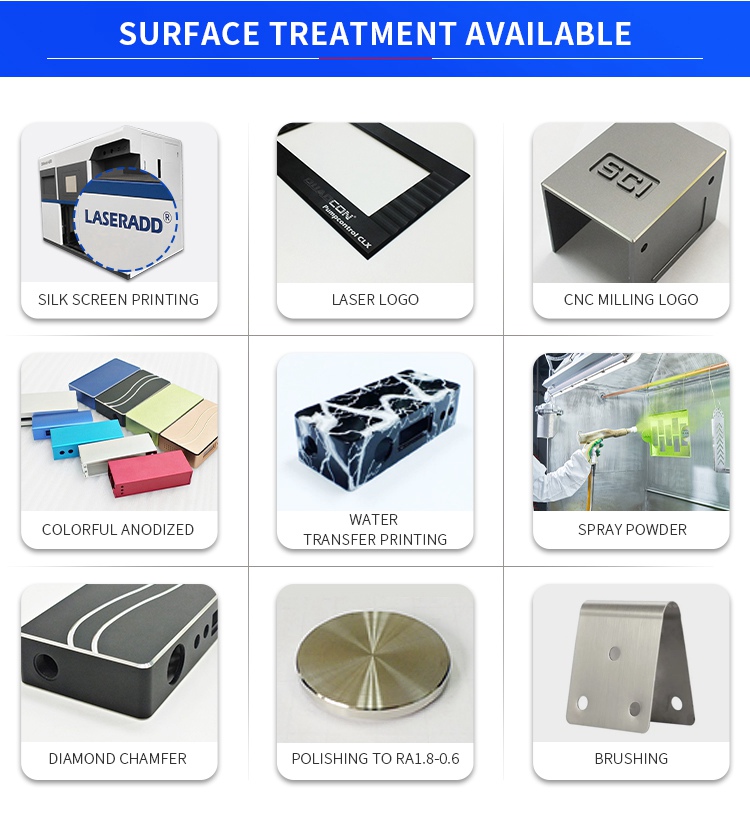

Different surface treatment for your different color requirement;

Color based on Pantone Color Guide;

Material is the same quantity standard with iphone's.

We have CNC Aluminum Keyboard for sale, many authoritative certifications, safety and quality let you rest assured, you can get the certificates, and you can check them online. Most of our products are processed products, please consult us for details. We carefully select the material, the surface is smooth, the hardness is high and the toughness is high, and the service life is long.

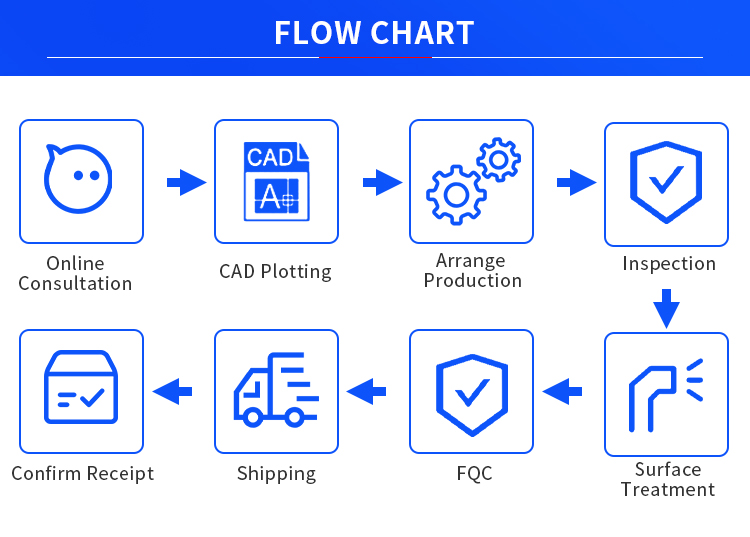

The CNC Aluminum Keyboard Case we produce is stable in structure, easy to install and use, saves time and effort, and has many applications. Precise processing, according to the documents you provide, we have a team to produce, size standard. Our customization process is convenient and experienced.

Our years of industry experience, integrity, hard work, innovation, production of CNC Keyboard Case Reddit. Lathe processing mainly uses turning tools to turn rotating workpieces. Lathes are mainly used to process shafts, disks, sleeves and other workpieces with rotating surfaces, and are the most widely used type of machine tool processing in machinery manufacturing and repair factories. Processing of our various parts.

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T, etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1, TA2/GR2, TA4/GR5, TC4, TC18, etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM, Acrylic, PC, etc. | |

| Finish | Sandblasting, Anodized color, Blackening, Zinc/Nickl Plating, Polish, |

| Powder coating, Passivation PVD, Titanium Plating, Electro galvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing, Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling Machine, Laser Cutting Machine, etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

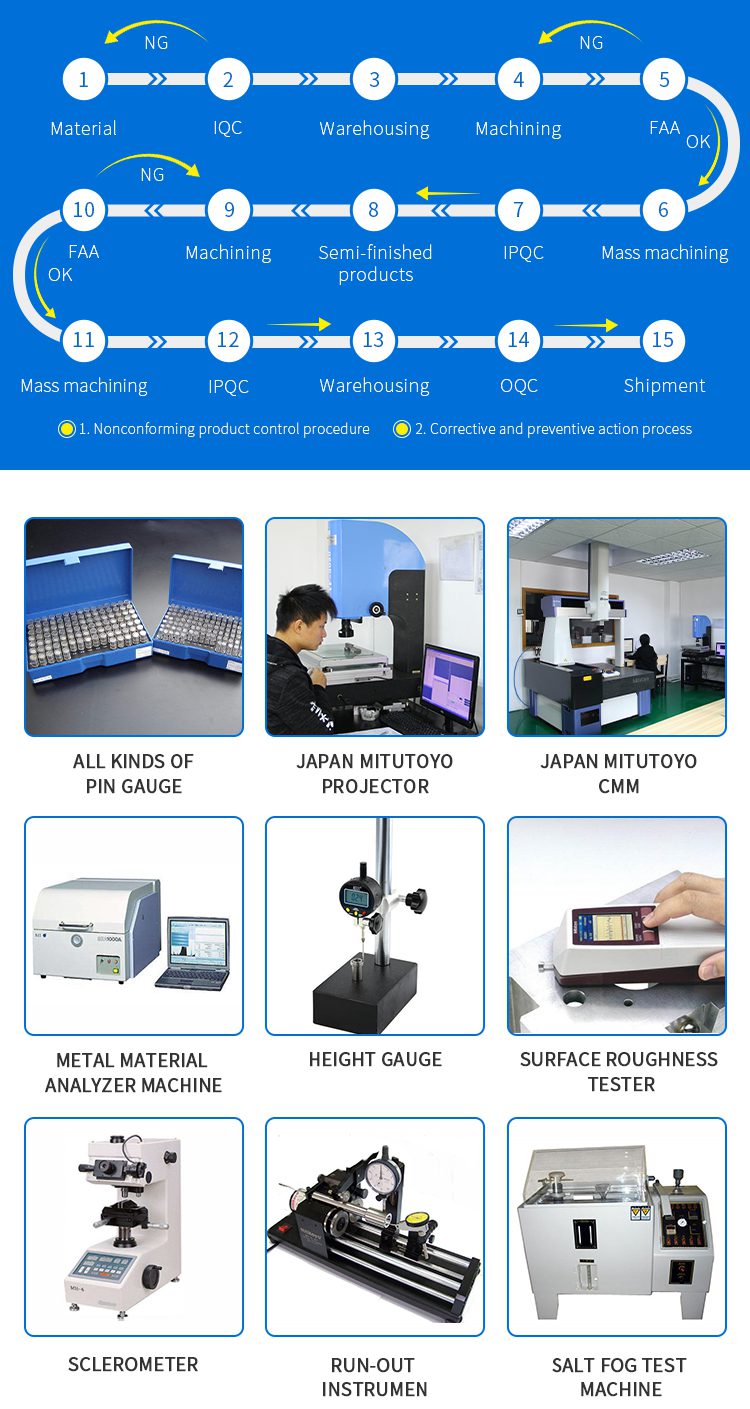

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier, CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |