Steel Processing And Bending Parts

High speed stainless steel CNC milling machining;

Control the tolerance within ±0.001mm;

10+ years experienced and professional operating personnel;

3-5 work days machining sample for you;

Engineer team help to revise the design to be more suitable for machining.

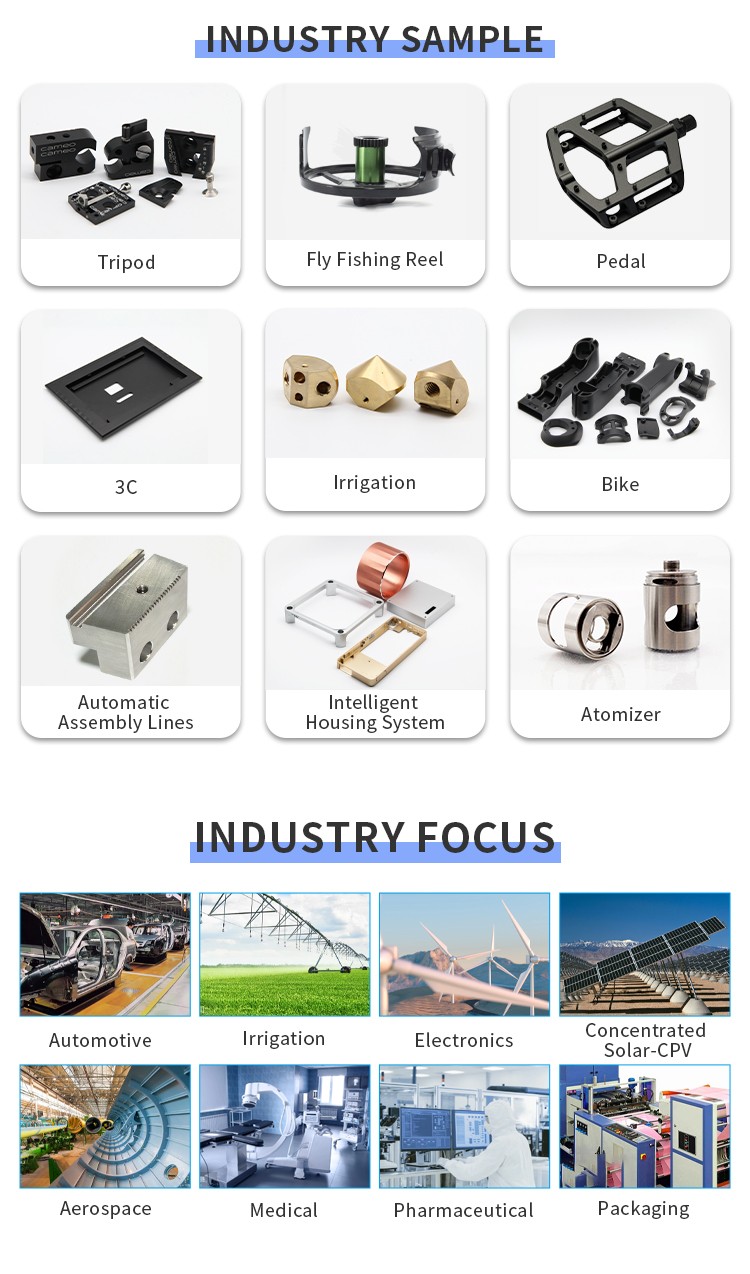

OEM Factory Milling Parts Custom High Precision Cnc Milling Stainless Steel Parts CNC Milling Accessories CNC Machining Parts

We have CNC Machining for sale, carefully selected materials, and the quality is assured. We have a variety of specifications, a wide range of uses, considerate service, and support customization. We use high-quality materials with sufficient strength, high overall hardness, not easy to be damaged and deformed, and have a long service life. It is very convenient to use standard accessories.

We adopt CNC core walking, CNC core walking machine tools, one-time production, fast processing speed and low cost. We are specialized in hardware processing. Good craftsmanship, good equipment, good technology, good service, because we are professional.

CNC machining is a new type of machining technology. The programming of machining programs can process all the functions required by all functional parts, including threaded holes and their precise surfaces. We have different specifications of CNC Drone Parts for sale, high-quality parts, durable, honest merchants, and complete accessories.

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM,Acrylic, PC, etc. | |

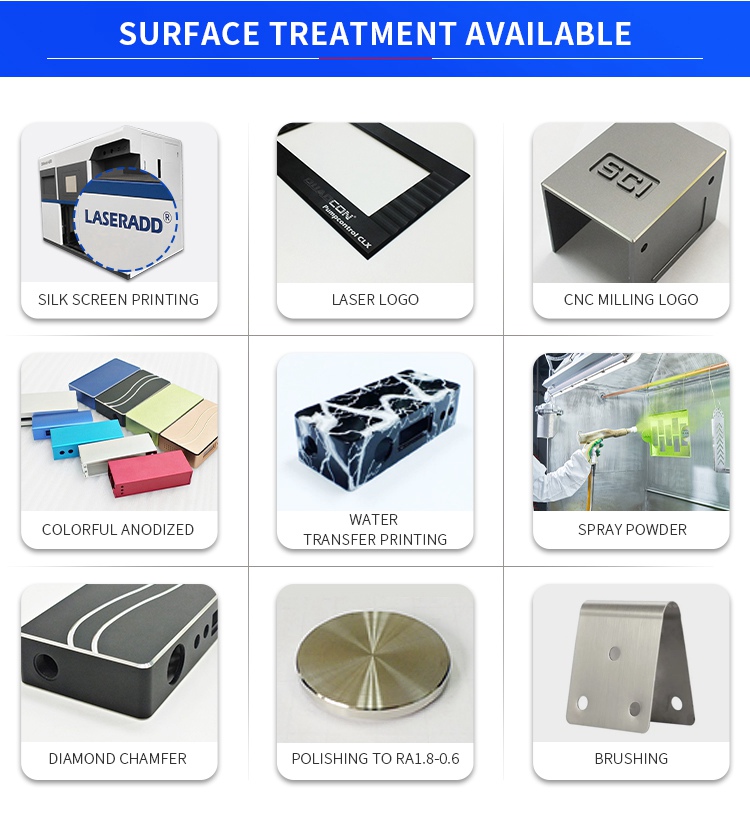

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish, |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling machine, Laser Cutting Machine,etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

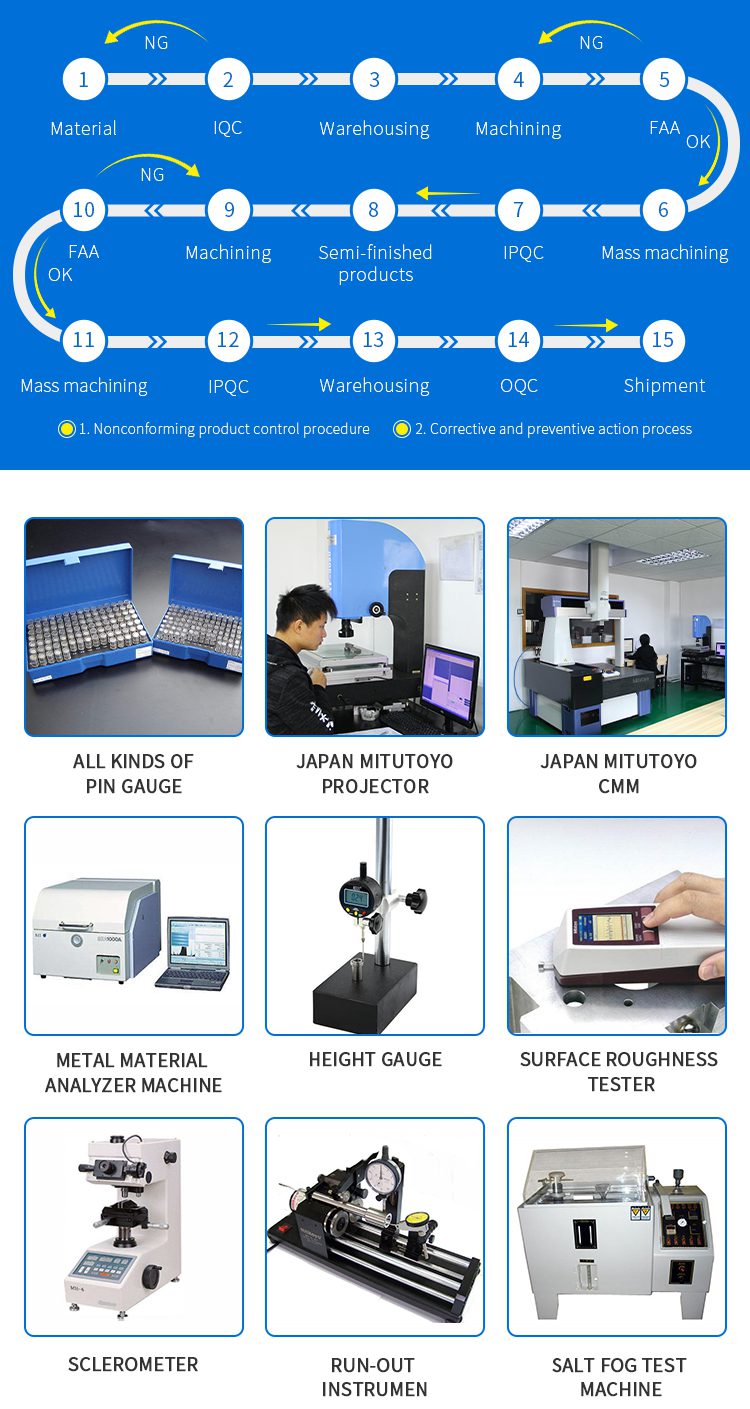

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |