Steel Processing Supports Customization

High precision metal stamping parts processing; (medium wire cutting processing, mechanical parts, mold parts, various non-standard parts)

According to the processing difficulty of metal stamping parts samples or drawings;

Various metals (copper, aluminum, 45# steel, casting, cr12 steel, SKD11)

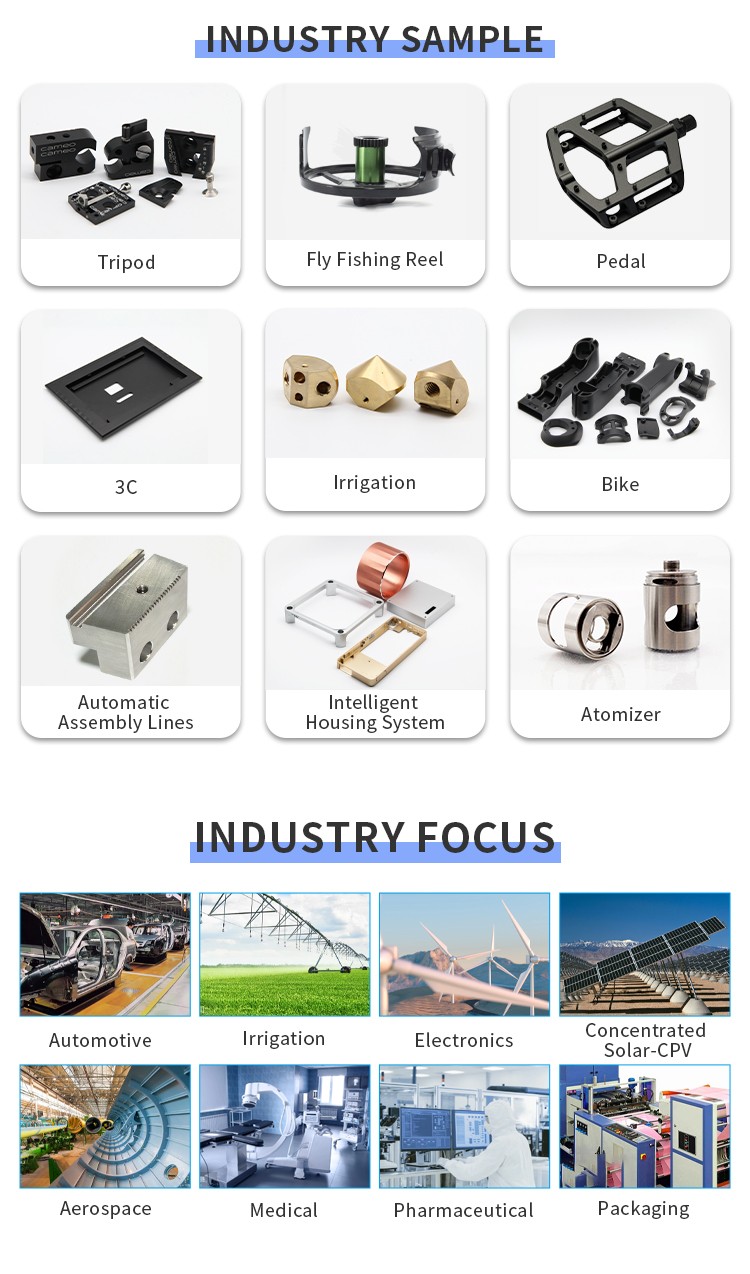

OEM Factory Milling Parts Custom High Precision Cnc Milling Stainless Steel Parts CNC Milling Accessories CNC Machining Parts

High-quality Aluminum Steel Machining, focusing on R&D, manufacturing, processing and sales of aluminum alloy products. The materials we produce are all real materials with guaranteed quality. Turning refers to a part of lathe processing and mechanical processing. Lathe processing mainly uses turning tools to turn rotating workpieces. Lathes are mainly used to process shafts, disks, sleeves and other workpieces with rotating surfaces, and are the most widely used type of machine tool processing in machinery manufacturing and repair factories.

Special materials can be customized Bearing Steel Machining, quality assurance, delivery service, quality assurance, welcome to our company for reference. The company's business ideas continue to improve, continue to develop, strictly control the production process, overcome technical bottlenecks, pursue technological innovation, and improve product quality. The company's integrity, strength and product quality have been recognized by the industry.

If you have a need, you need Custom Steel Machining. May wish to try to look at our website, we have aluminum alloy shell mirror base processing. Durable. Wear-resistant and anti-corrosion, showing quality between square inches. Factory direct sales, support customization. Craftsmanship you can trust. We pay attention to details in every step of production and pursue high-quality products.

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM,Acrylic, PC, etc. | |

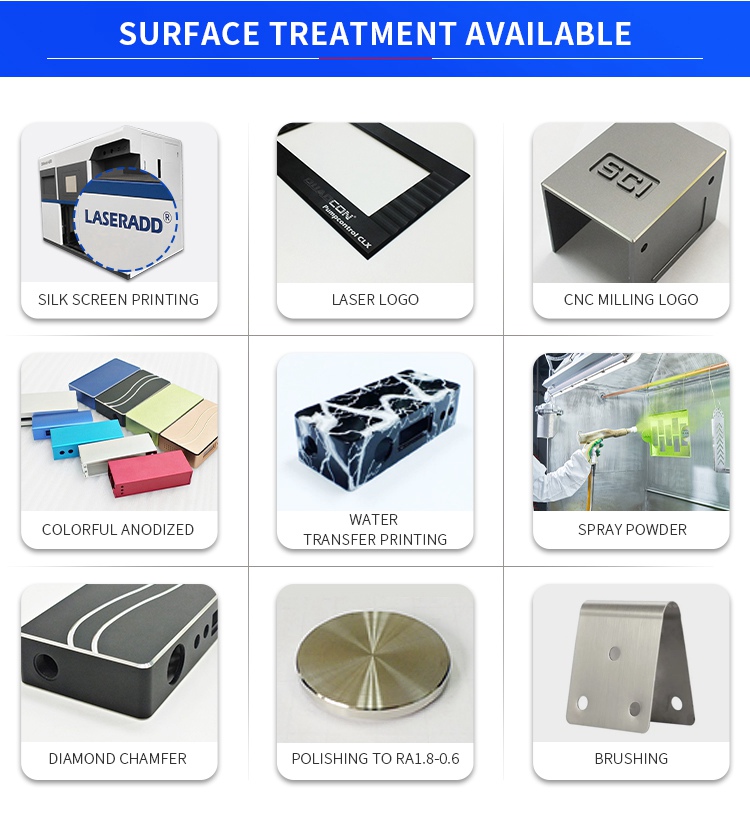

| Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish, |

| Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling machine, Laser Cutting Machine,etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

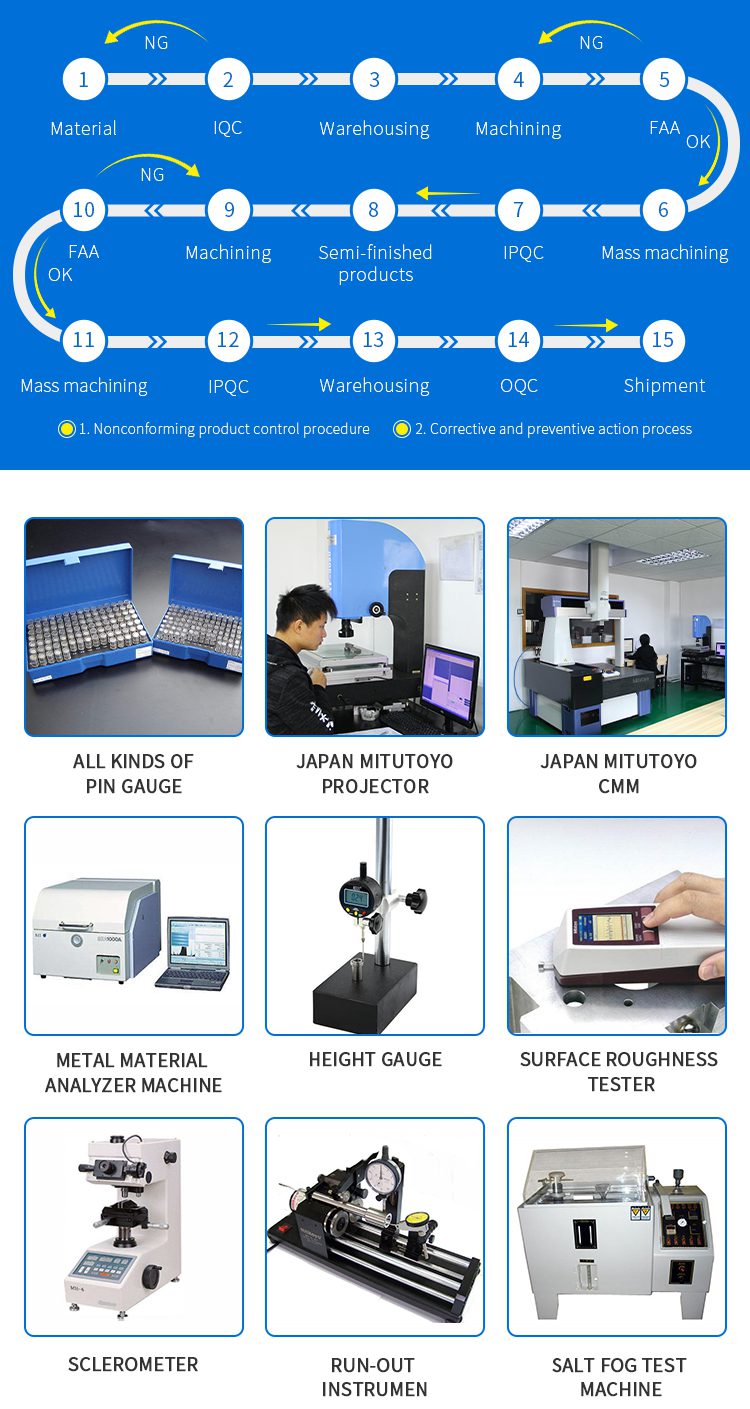

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |