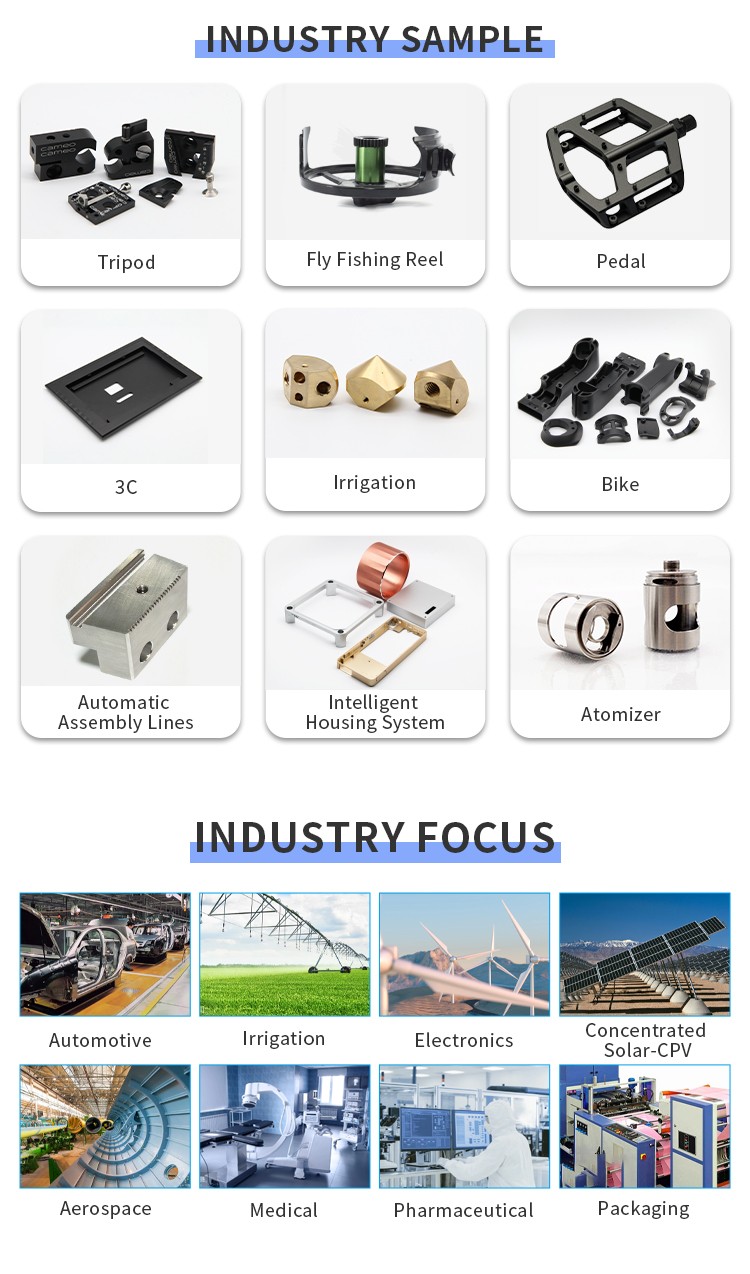

CNC Machining Of Remote Control Car Parts

Customized machining with your logo

High precision CNC milling machining

Different color anodized based on your requirement

Sales team 24 hours online

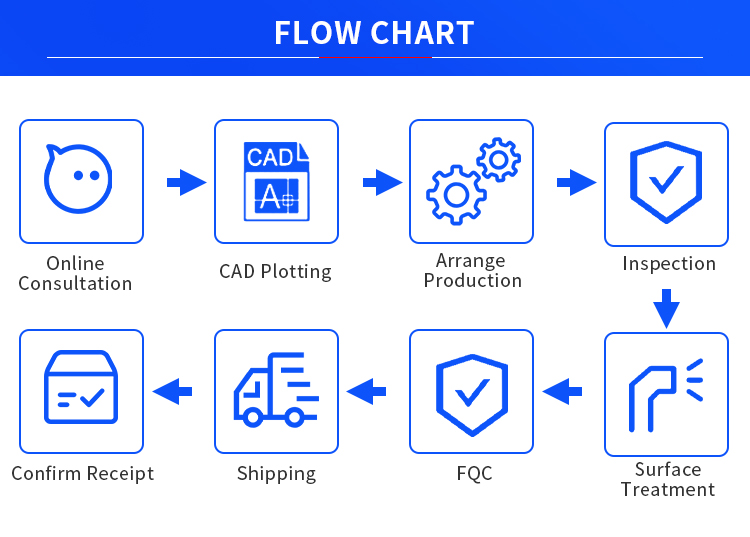

CNC parts processing is the process of using computer numerical control technology to control processing equipment for CNC Drone Parts processing. Its basic process includes four links: design, programming, processing and testing. First, the design needs to be carried out, and the design drawings are converted into CAD files. Next, use CAD files to perform CAM programming to generate machining programs. When programming, factors such as the nature of the material, the selection of the tool, and the setting of cutting parameters need to be considered.

Before performing CNC Machining, it is necessary to select appropriate materials and tools, and set the processing parameters. Then, input the machining program into the controller of the CNC machine tool to start the machining process. During the machining process, the CNC machine tool will precisely control the tool to perform cutting, milling, drilling and other processing operations on the workpiece according to the preset programs and instructions.

After the processing is completed, inspection is required to check whether the dimensional accuracy and surface quality of the parts meet the requirements. If it does not meet the requirements, the processing program and parameters need to be optimized and processed again. CNC parts processing has the advantages of high precision, high efficiency, and good consistency, and is widely used in aerospace, automotive, machinery, electronics, medical and other fields. It should be noted that CNC parts processing requires skilled technicians and appropriate equipment to complete. If you do not have relevant experience and equipment, you can consider seeking help from professional processing manufacturers or service providers. We have Automotive CNC Machining for sale, if you are interested, you can consult us.

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T, etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1, TA2/GR2, TA4/GR5, TC4, TC18, etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM, Acrylic, PC, etc. | |

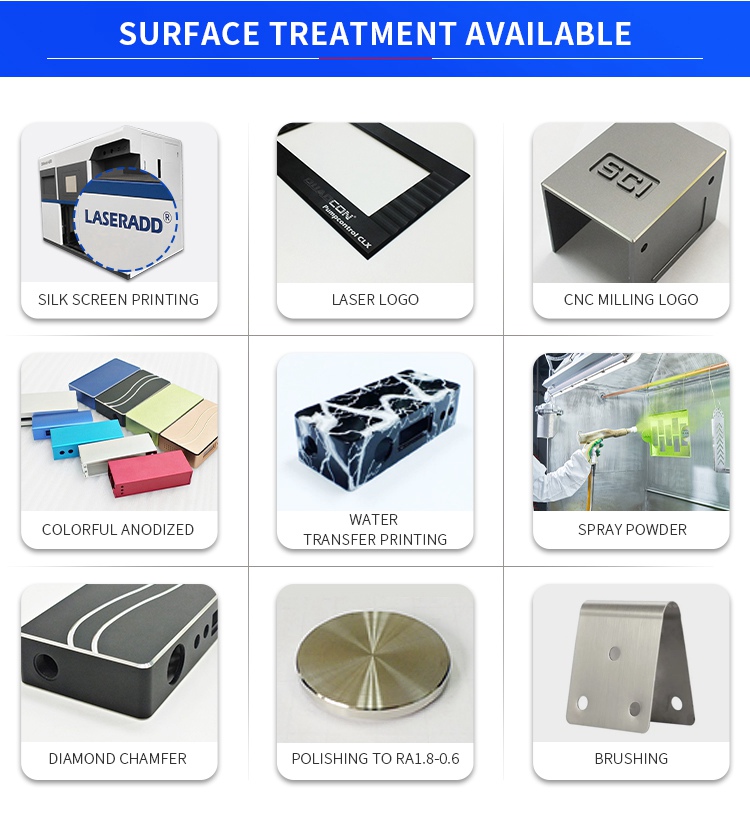

| Finish | Sandblasting, Anodized color, Blackening, Zinc/Nickl Plating, Polish, |

| Powder coating, Passivation PVD, Titanium Plating, Electro galvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing, Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling Machine, Laser Cutting Machine, etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

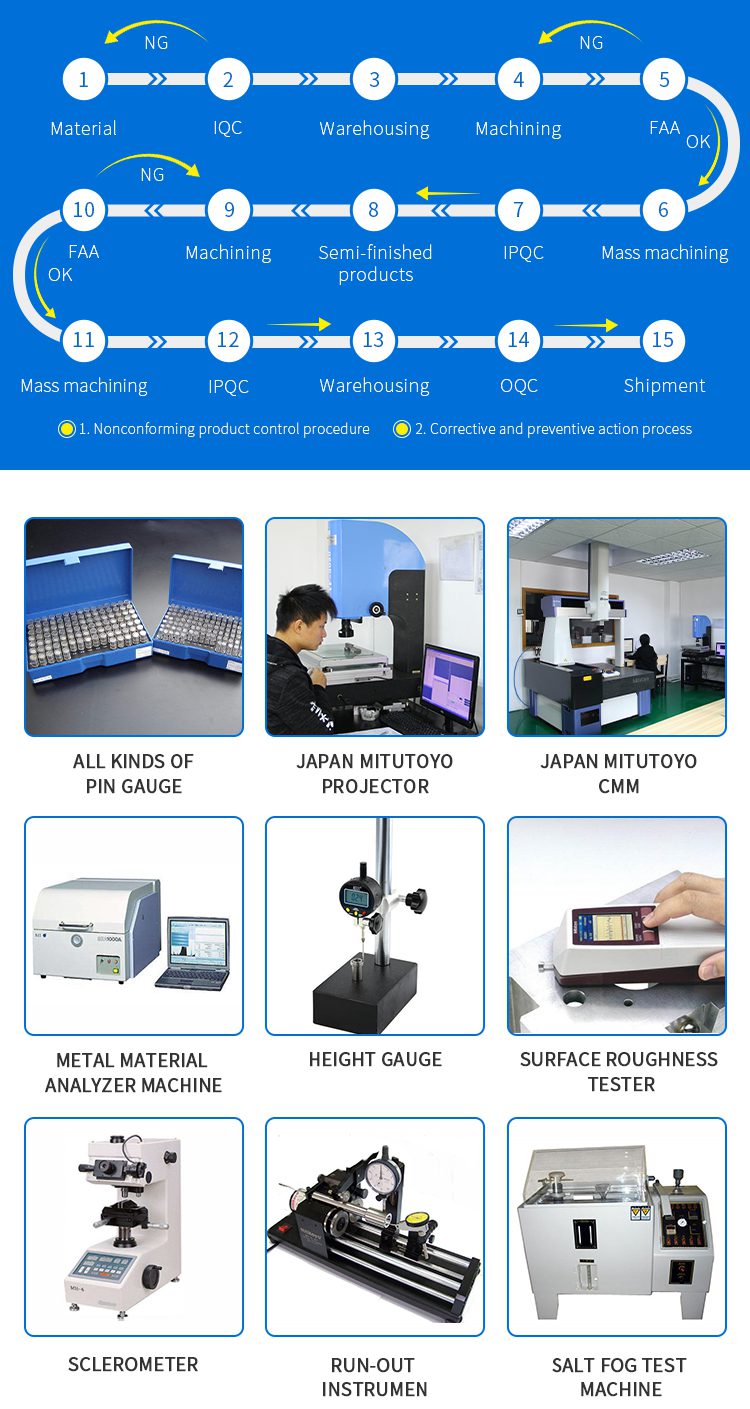

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier, CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |