Mini Box Chassis Sheet Metal Processing

Mini computer enclosure machined by CNC milling and sheet metal fabrication;

120# sand-blasting with colorful anodized;

Machined based on your drawing;

Supply one-stop machining service.

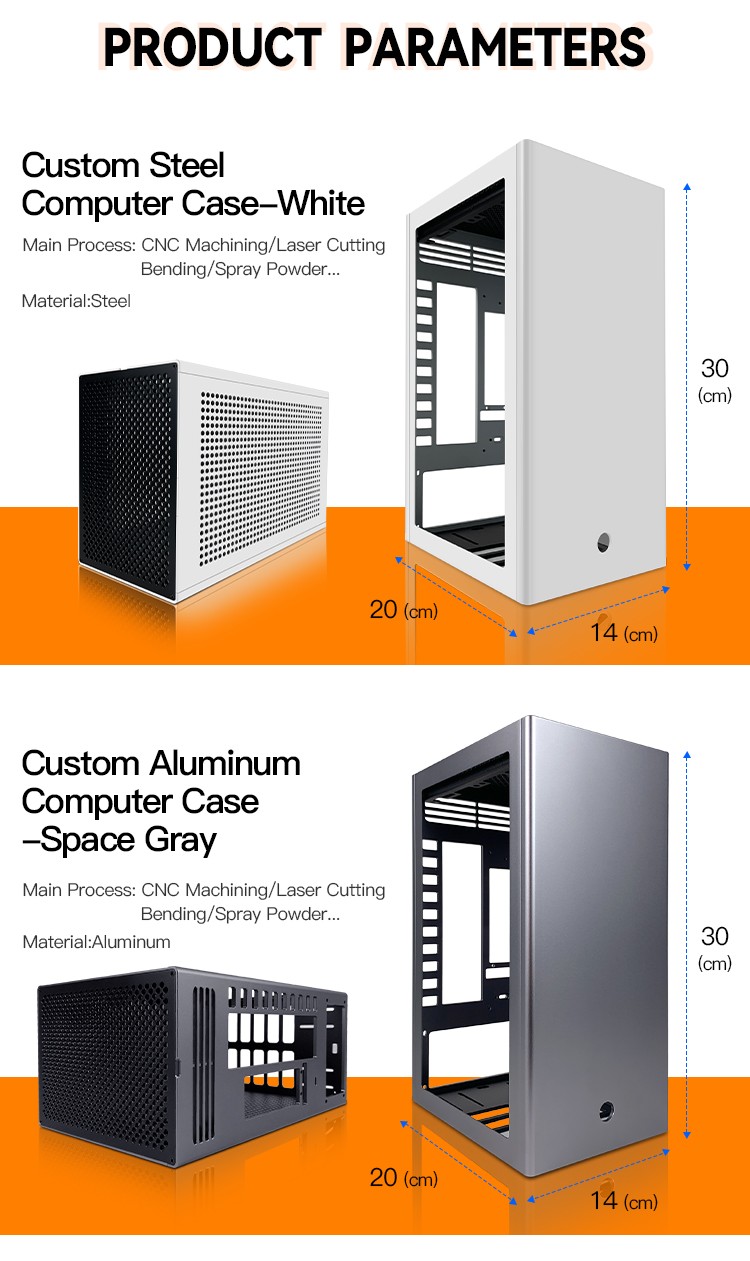

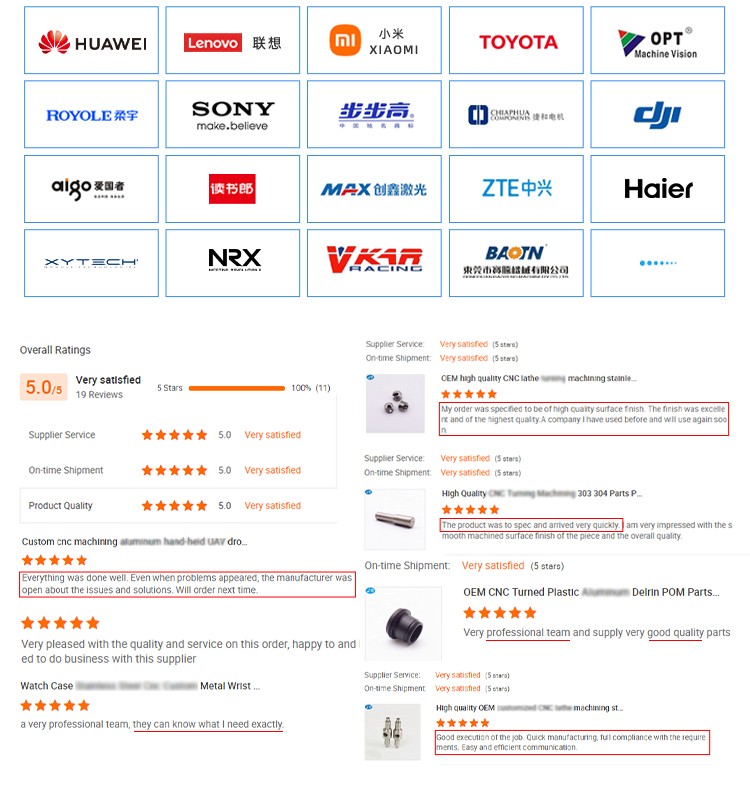

The quality of the products we produce is assured, the price is competitive, and the drawings and samples are customized. Details cast good quality. We focus on every detail and satisfy every customer. All kinds of excellent metal materials are selected, raw materials are processed, and they are sturdy and durable. Ingenious craftsmanship, fine polishing, processing by professional processing masters who have worked for many years.

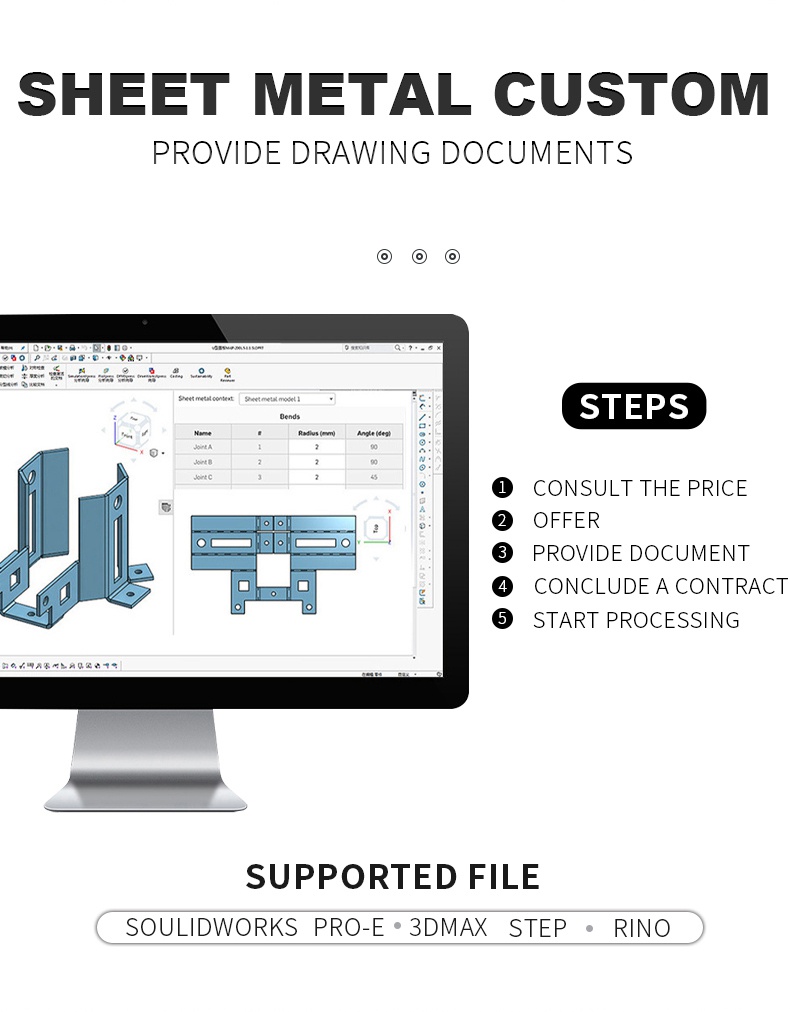

We have Sheet Metal Fabrication products. Sheet metal processing is a key technology that sheet metal technicians need to master, and it is also an important process for sheet metal product forming. Sheet metal processing includes traditional cutting, blanking, bending and forming and other methods and process parameters, as well as various cold stamping die structures and process parameters, various equipment working principles and operating methods, as well as new stamping technology. and new technology. Sheet metal processing of parts is called sheet metal processing.

We have Sheet Metal Cabine and Sheet Metal Enclosure for sale, which can be processed by stamping, bending, drawing, etc. If you are interested, you can consult us.

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T, etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1, TA2/GR2, TA4/GR5, TC4, TC18, etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM, Acrylic, PC, etc. | |

| Finish | Sandblasting, Anodized color, Blackening, Zinc/Nickl Plating, Polish, |

| Powder coating, Passivation PVD, Titanium Plating, Electro galvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing, Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling Machine, Laser Cutting Machine, etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

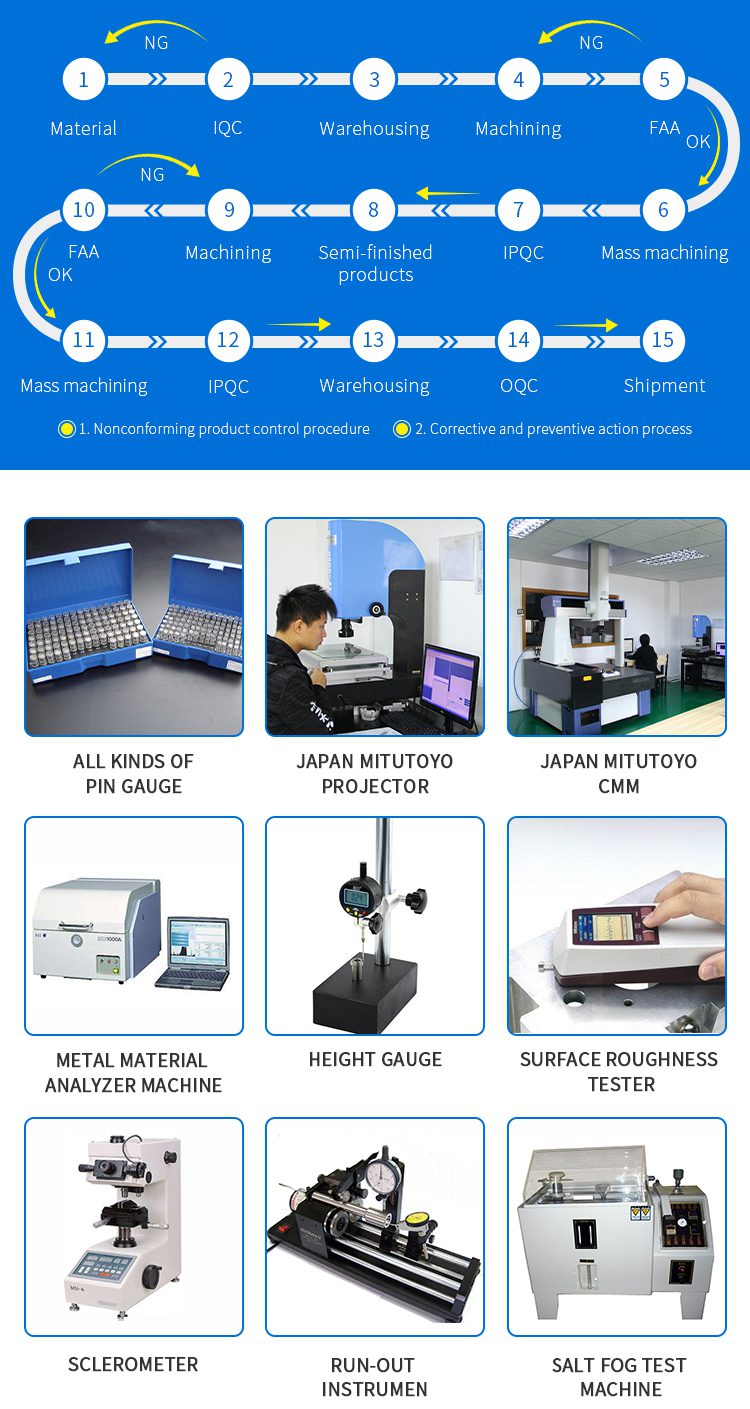

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier, CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |