Precision Parts Processing Machinery Shaft Parts Processing

Stainless steel CNC turning machining customized shaft;

Import machine to ensure high precision;

Supply blackening, plating, polish, etc. surface treatment;

Own precision centerless grinding machines, straightening machines, precision polishing machines, precision lathes, and drilling and milling machines;

According to the different requirements of users, it can be processed, quenched and tempered, high frequency, etc. to meet the different requirements of customers.

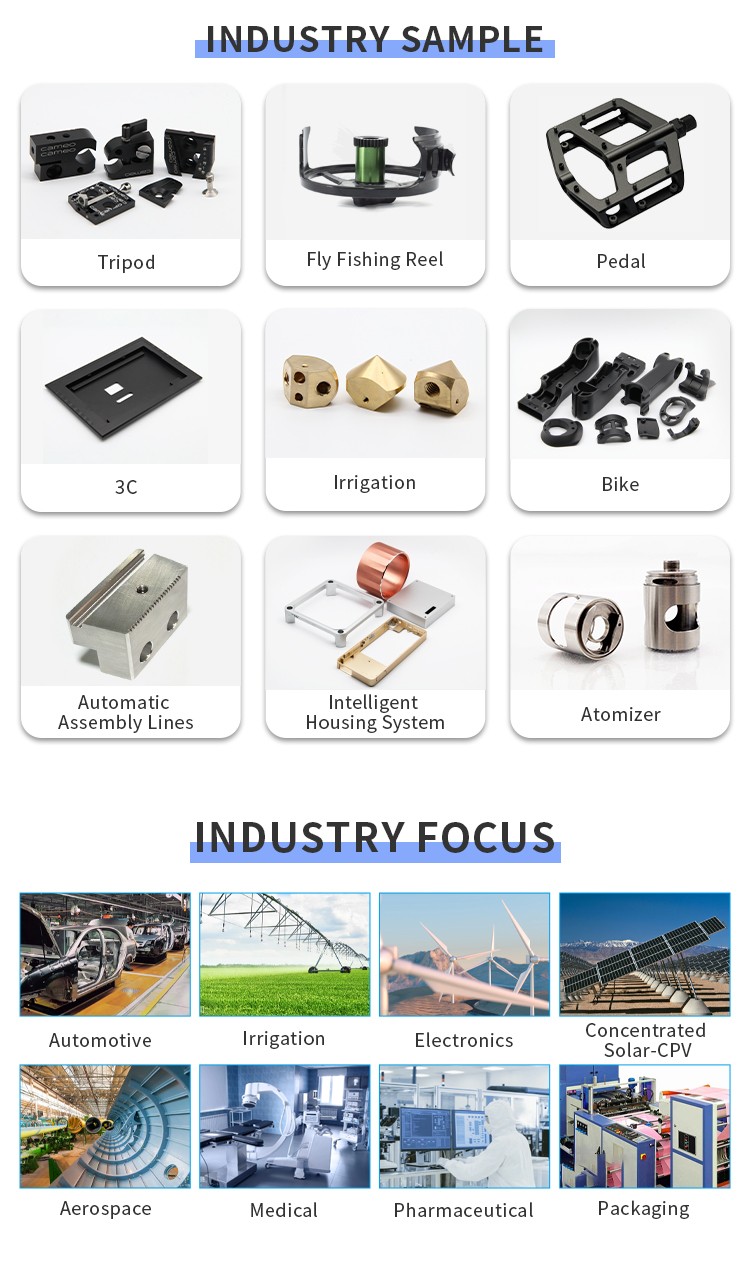

OEM High Precise Tolerance Customized CNC Turning Machining Stainless Steel Custom CNC Turning Auto Part Turning Shaft

We have Short Mechanical Shaft Design, which is professionally designed to create high-quality products for you. We have high-quality sources, our structure is stable, the technology is mature, and the use time is long. It is a powerful manufacturer with high cost performance, various specifications and wide application. We use high-quality materials, and the surface treatment is not easy to rust.

We have a variety of Short Mechanical Shaft Pumps in production, strictly controlled, with various specifications, meticulous workmanship, and good workmanship. High-quality production technology, surface processing, and non-oxidative design increase the strength and hardness of the product. Process forging, the product is forged through multiple processes, the surface is smooth and burr-free.

The Short Mechanical Shaft Parts we produce are of high-precision quality, a one-stop parts processing service manufacturer, the surface is smooth and burr-free, the workmanship is excellent, it meets the needs, and it is durable. We have mature technology, and the products have been processed layer by layer, so they can be used for a long time and are not easy to rust.

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T, etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1, TA2/GR2, TA4/GR5, TC4, TC18, etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM, Acrylic, PC, etc. | |

| Finish | Sandblasting, Anodized color, Blackening, Zinc/Nickl Plating, Polish, |

| Powder coating, Passivation PVD, Titanium Plating, Electro galvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing, Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling Machine, Laser Cutting Machine, etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

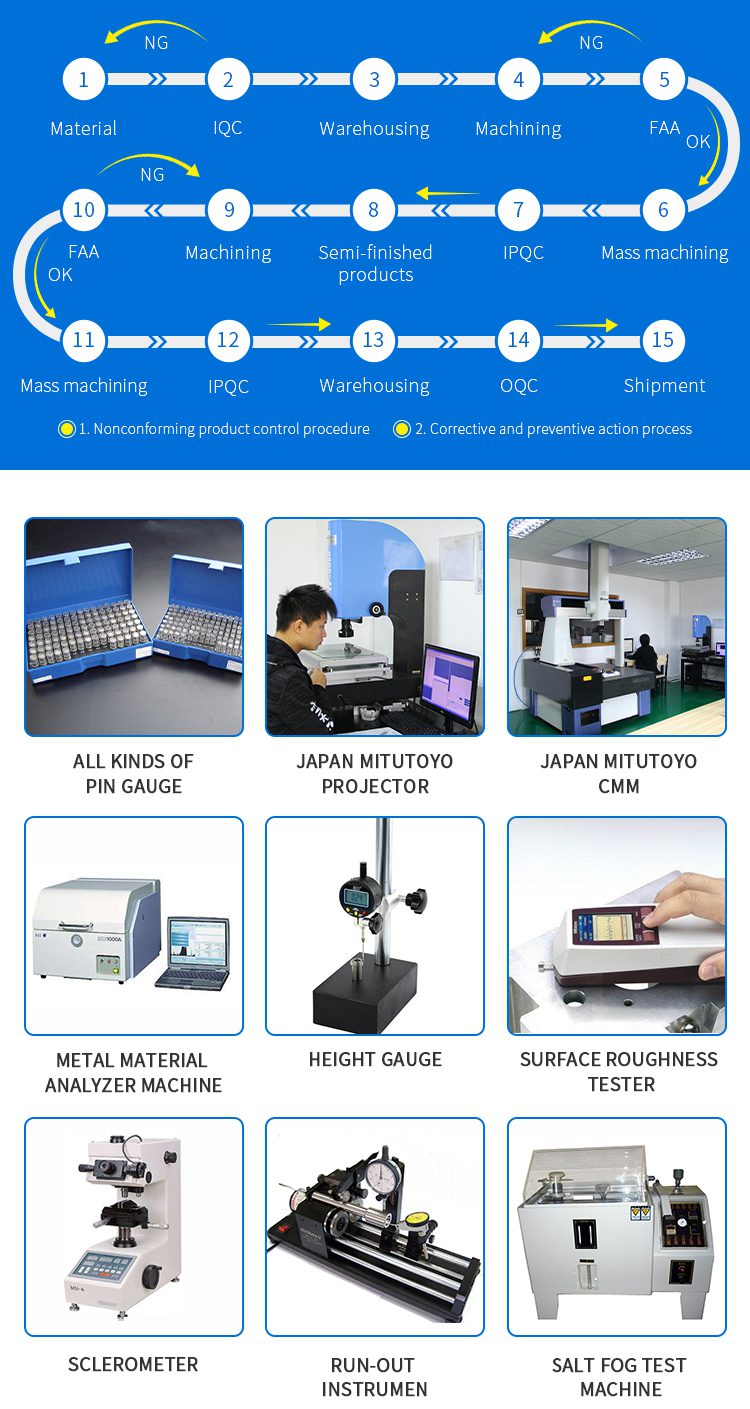

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier, CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |