Non-Standard Custom Processing Of Mechanical Shaft Parts

Stainless steel CNC turning machining customized shaft;

Import machine to ensure high precision;

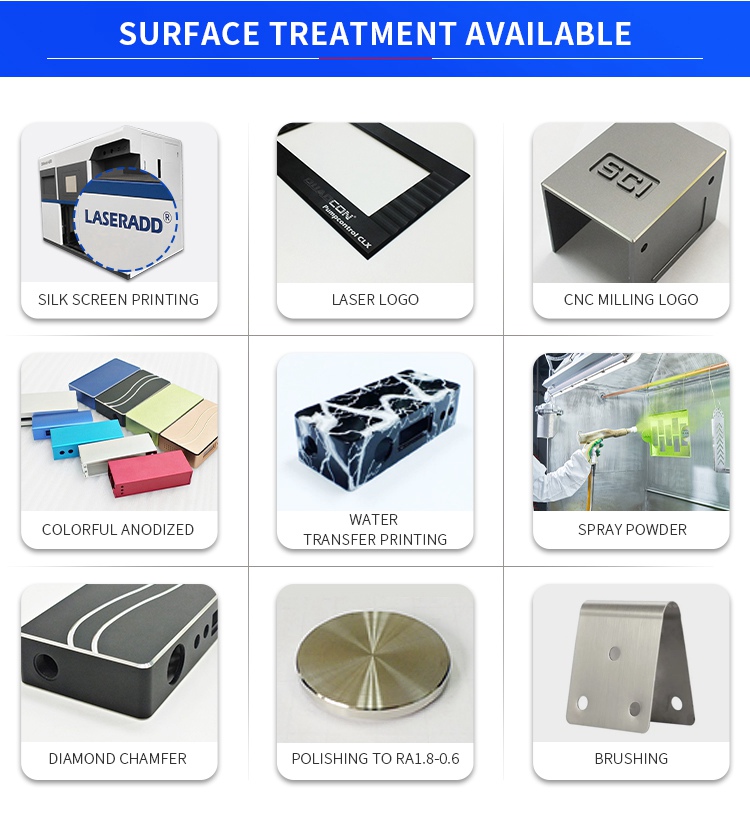

Supply blackening, plating, polish, etc. surface treatment;

Own precision centerless grinding machines, straightening machines, precision polishing machines, precision lathes, and drilling and milling machines;

According to the different requirements of users, it can be processed, quenched and tempered, high frequency, etc. to meet the different requirements of customers.

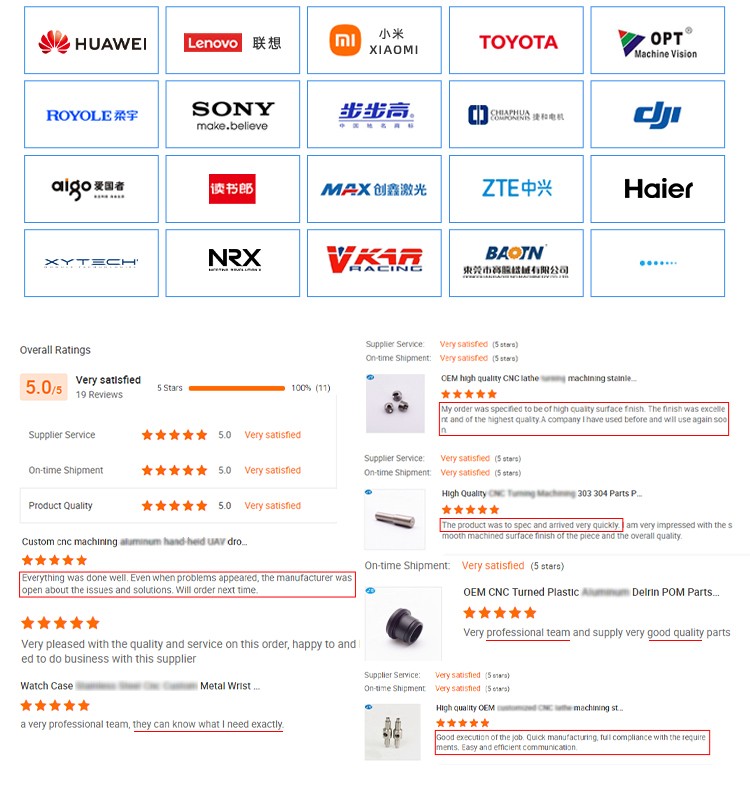

We are committed to high-quality ultra-precision equipment, parts processing, manufacturing and research and development. We always insist on independent research and development and technological innovation. Quick proofing, we require quality, reputation first, considerate service, warmly welcome new and old customers to cooperate wholeheartedly, and achieve great goals together. Companies adhering to the "customer first, forge ahead" business philosophy, adhere to the "customer first" principle to provide our customers with quality services. Welcome to consult us!

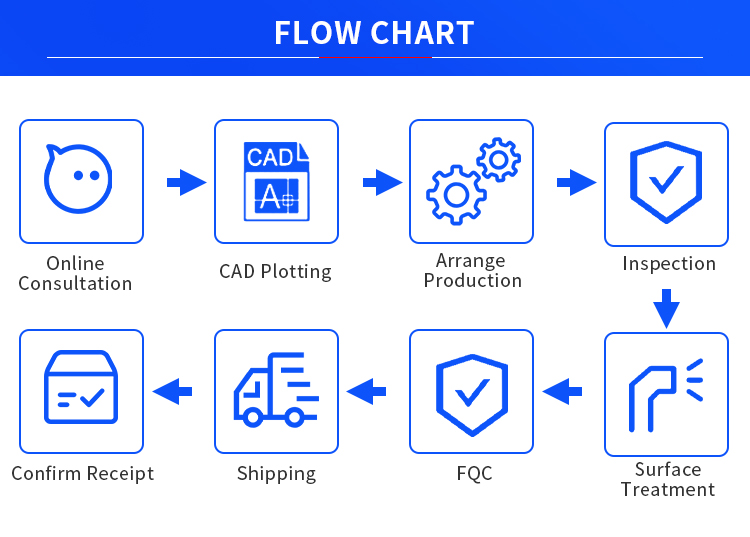

CNC Turning automatically processes the processed parts according to the pre-programmed processing program. We write the machining process route, process parameters, tool motion trajectory, displacement, cutting parameters and auxiliary functions of the part into a machining program list according to the instruction code and program format specified by the CNC machine tool, and then record the content of the program list. On the control medium, it is then input into the numerical control device of the numerical control machine tool, thereby directing the machine tool to process the parts.

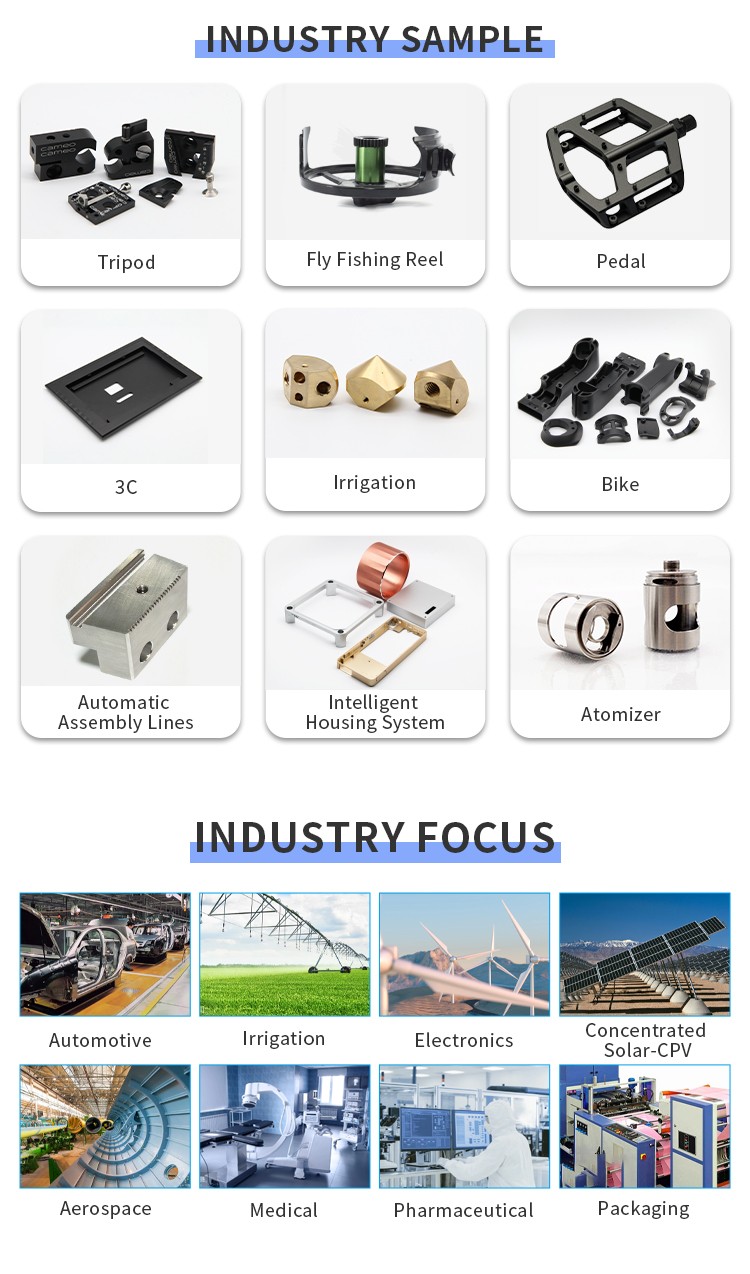

We have different CNC metalworking, such as Mechanical Shaft and Metal Sleeve. You can choose according to your needs, or consult us to customize high-quality products for you.

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T, etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1, TA2/GR2, TA4/GR5, TC4, TC18, etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM, Acrylic, PC, etc. | |

| Finish | Sandblasting, Anodized color, Blackening, Zinc/Nickl Plating, Polish, |

| Powder coating, Passivation PVD, Titanium Plating, Electro galvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing, Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling Machine, Laser Cutting Machine, etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

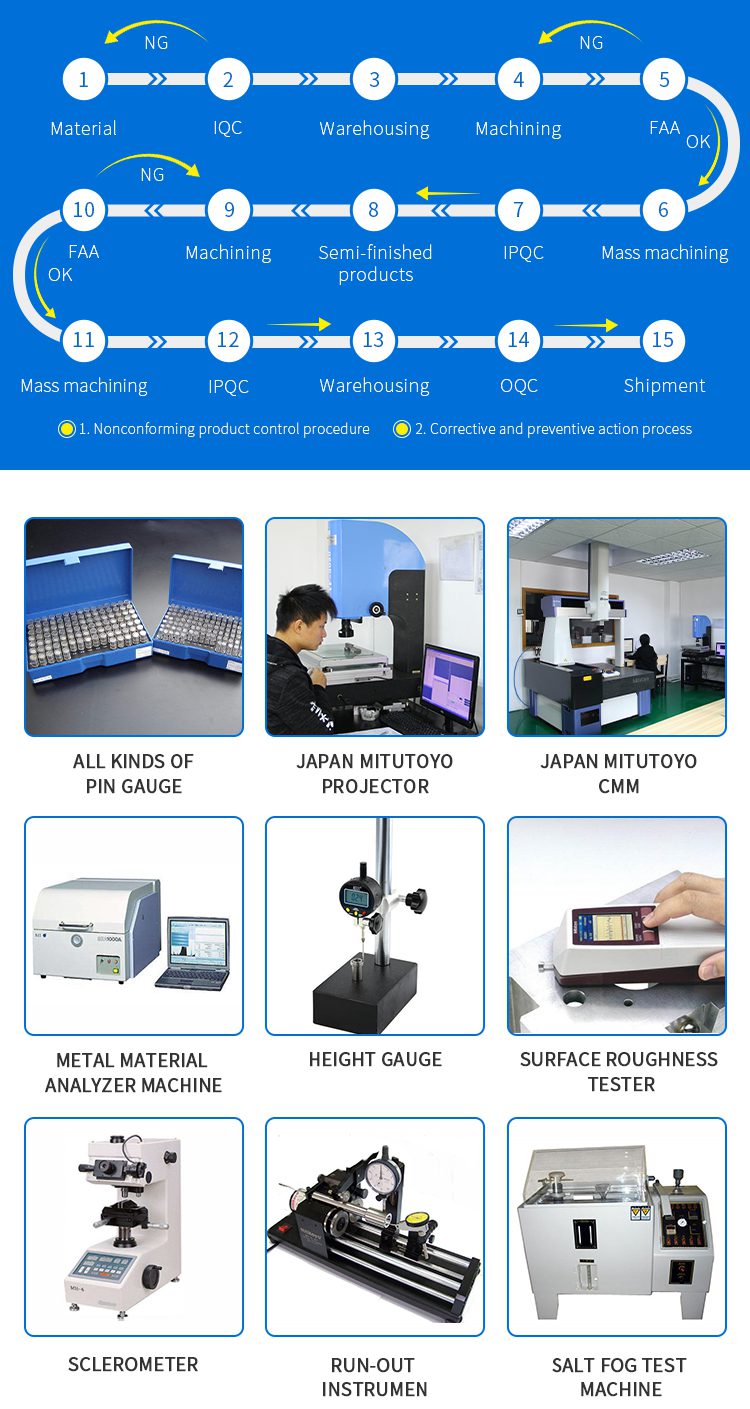

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier, CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |