Direct Supply Of High-Quality Parts For Mechanical Shafts

Stainless steel CNC turning machining customized shaft;

Import machine to ensure high precision;

Supply blackening, plating, polish, etc. surface treatment;

Own precision centerless grinding machines, straightening machines, precision polishing machines, precision lathes, and drilling and milling machines;

According to the different requirements of users, it can be processed, quenched and tempered, high frequency, etc. to meet the different requirements of customers.

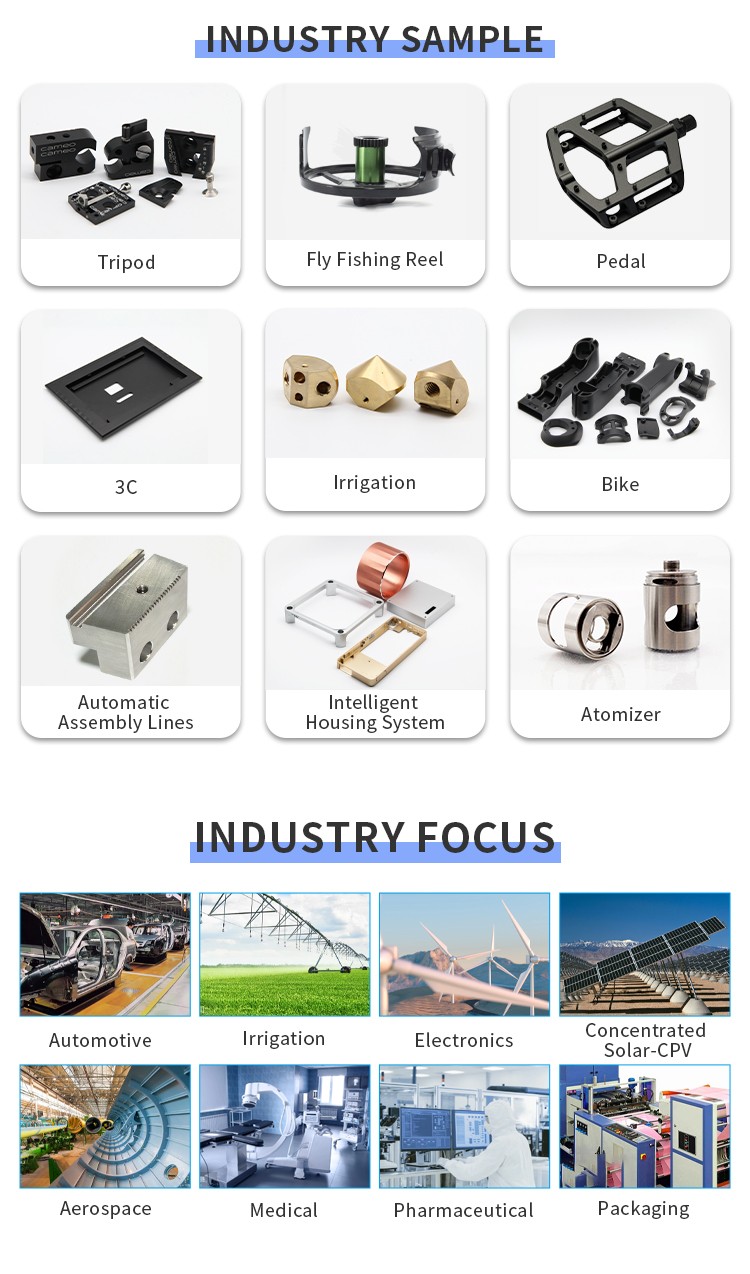

We have Mini computer enclosure for sale, high strength, light weight, high assembly precision. On the premise of satisfying the function, we constantly upgrade the overall lightweight, degree and assembly time. Because we are the source manufacturer, we have excellent material selection and fine workmanship. Support processing customization, quality control.

We have different Sheet Matel Enclosures with complete wiring types and reasonable prices. Our Electronic Equipment Co., Ltd. has strong strength, respects credit, abides by contracts, strictly selects materials, and has won the trust of customers with its multi-variety management characteristics and the principle of small profits but quick turnover. If you are interested in us, you can contact us.

More about Sheet Metal Fabrication, all in our website, you can go to our website to browse, excellent material selection, stable performance, choose the right one carefully, the right product starts from the raw material, and checks layer by layer.

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T, etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1, TA2/GR2, TA4/GR5, TC4, TC18, etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM, Acrylic, PC, etc. | |

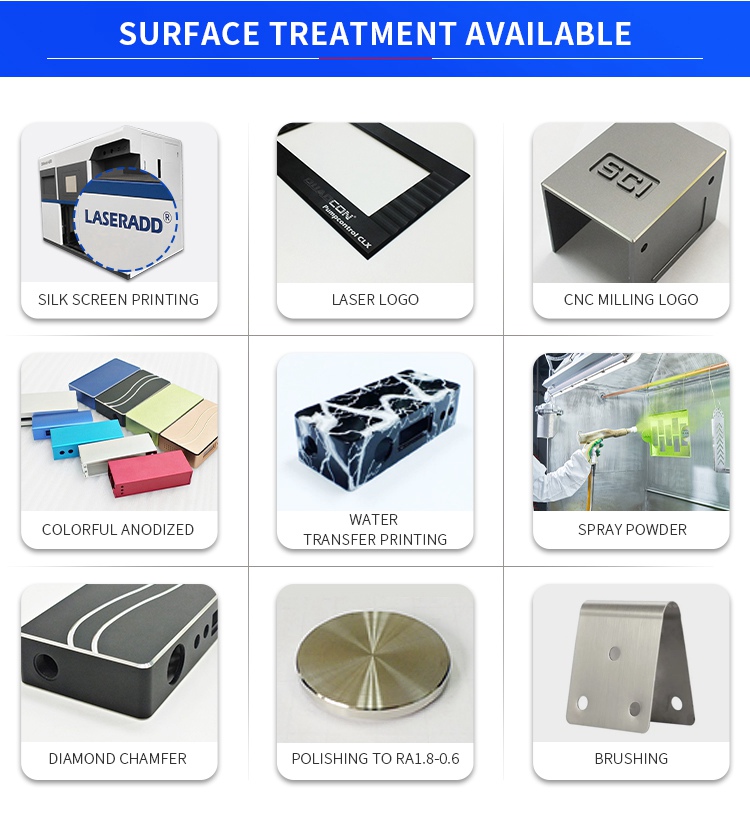

| Finish | Sandblasting, Anodized color, Blackening, Zinc/Nickl Plating, Polish, |

| Powder coating, Passivation PVD, Titanium Plating, Electro galvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing, Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling Machine, Laser Cutting Machine, etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

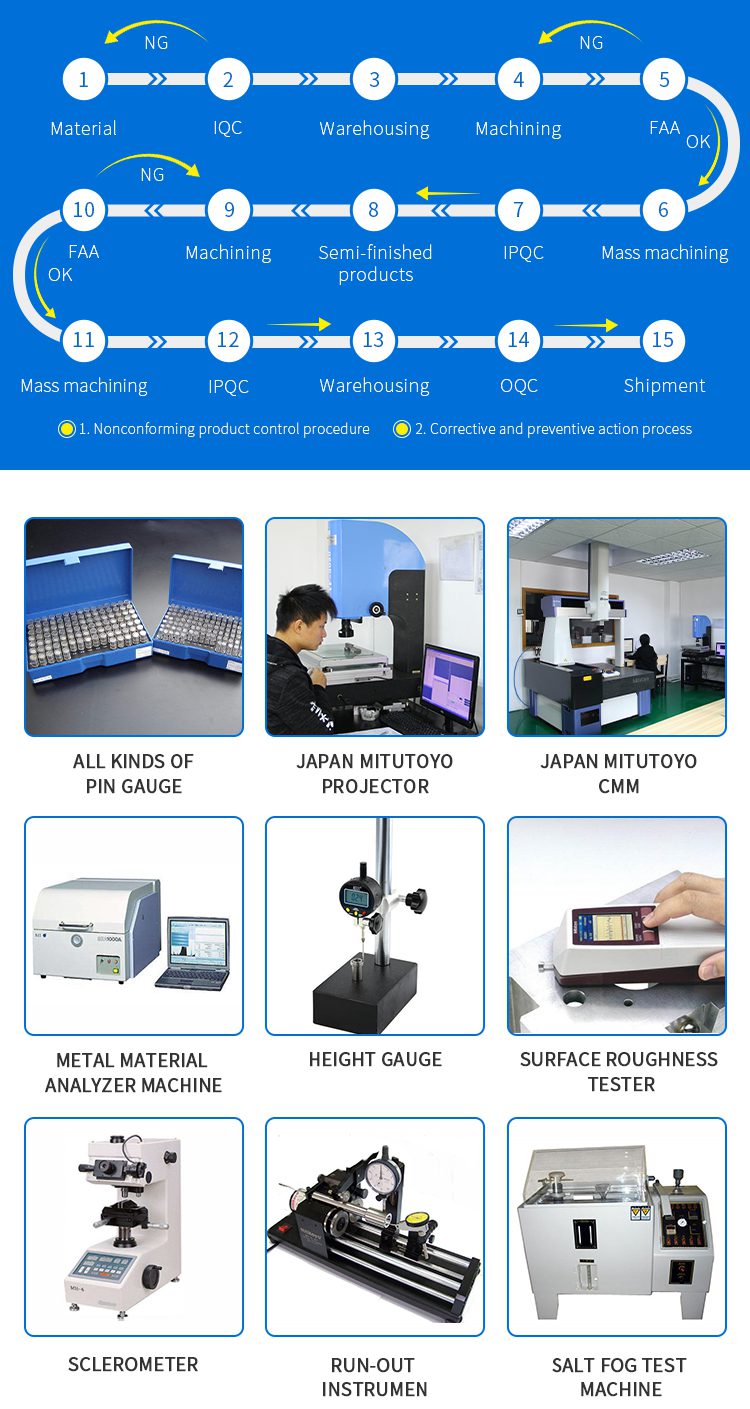

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier, CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |