What Are The Factors That Affect The Life Of Stamping Dies

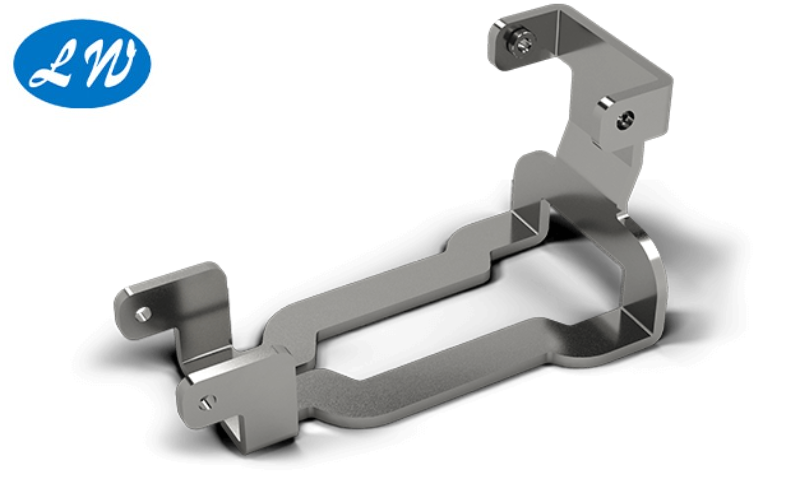

The relevant factors affecting the life of stamping dies are from design, use to maintenance. Only by doing a good job in each link can the service life of the die be better extended. The same goes for the parts production of quality CNC Drone Parts.

The design quality of the mold

1. Stamping process of parts

In stamping process design, avoid excessive design of process content, reasonable division of process content, avoid sharp corners in trimming and stamping die inserts, try to make material flow evenly in forming dies, avoid wrinkling and accumulation, and choose stamping process as much as possible Good raw materials, reduce stamping deformation force.

2. Reasonably design the mold structure

When designing the mold structure, the stress and structural strength of each structural part should be fully considered. A reasonable mold structure can reduce the mechanical load level of the mold and improve the bearing capacity of the mold.

3. Selection of mold material

The material division of each component should be carried out according to the stress of each component and the chemical composition, structure, hardness and metallurgical quality of the material itself. The processing process of the working parts of the stamping die is generally complicated and must be adapted to various complex processes such as cutting and heat treatment. .

4. Select the precision of the guiding mechanism

In order to improve the life of the mold, it is necessary to choose the correct precision and guiding form of the guiding mechanism according to the nature of the process and the precision of the parts. An accurate and reliable guiding mechanism is very important to reduce the wear of the working parts of the mold and avoid the problem of mold gnawing.

Mold manufacturing quality

1. Casting and forging quality

In the mold manufacturing stage, the quality control of mold materials is very important. Hidden defects during use may cause irreversible safety accidents and have a great impact on production.

2. Machining accuracy

The processing surface quality of the working parts of the mold has a major impact on the anti-bonding ability, wear resistance and fracture resistance of the mold. The machining accuracy of each part directly affects the overall accuracy of the mold. Parts with poor precision will be continuously damaged during the use of the mold. Creates friction that affects the overall life of the mold.

3. Assembly accuracy

For the assembly process of all the installation faces and reference faces that need to be assembled, the assembly process is carried out to ensure the quality of each process, and the assembly accuracy directly affects the product quality and mold life.

4. Heat treatment

Achieve the hardness, strength, toughness and wear resistance required for mold work, such as parts processed by Aluminum Machining. A good heat treatment process can give full play to the performance of the mold steel material, and an unreasonable heat treatment process will accelerate the wear of the mold, resulting in carbonization or insufficient hardness of the mold body, which will affect the life of the mold.

In the process of design, manufacture, use and maintenance of stamping dies, implement comprehensive die quality management and develop specialized manufacturing models, so as to better prolong the service life of dies and ensure the production quality of parts.

We have different CNC Machining production parts, you can consult us if you are interested.