Safety Technical Measures For Aluminum Shell Processing

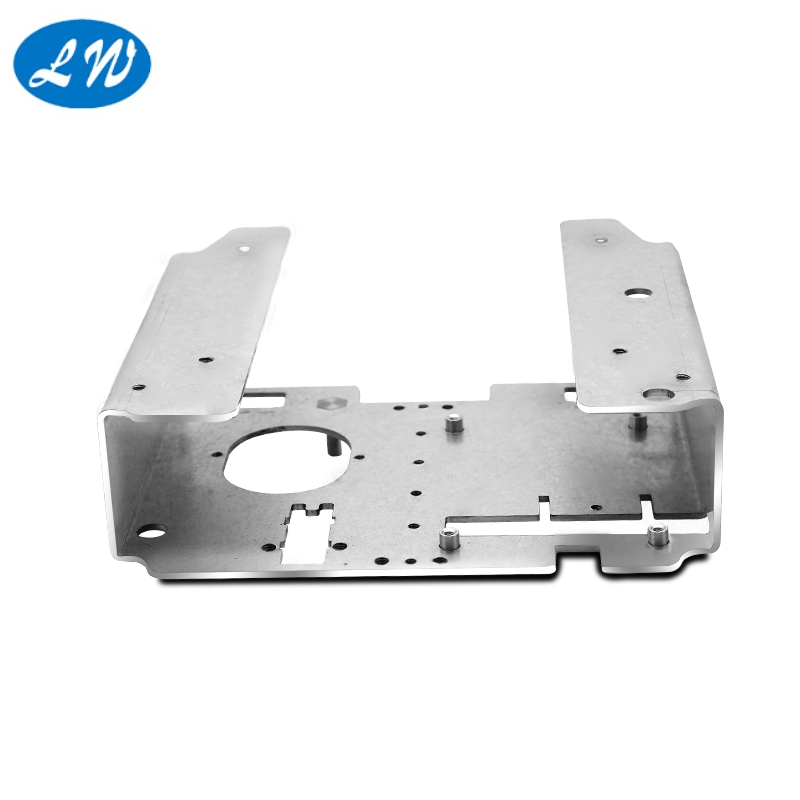

With the popularity of aluminum profiles, Aluminum Machining processed parts, etc., aluminum casings are increasingly used in electromechanical products, electronic instruments, mobile power supplies, photoelectric lighting and other fields. The aluminum shell can not only play the role of external protection, but also make full use of the space and play the role of heat dissipation. So what are the safety technical measures for aluminum shell processing? Next, introduce to everyone.

Aluminum shell processing safety technical measures:

1. The metal structure is easy to operate, safe and reliable, and the stamping process can be successfully completed without placing hands, arms, and heads in dangerous areas.

2. It is convenient and safe to adjust, install, maintain, transport and store, and will not cause accidents due to metal structure problems.

3. The structure of the pusher, pusher, and discharge plate must be safe and reliable.

4. When designing the aluminum alloy shell, if mechanization is required, the installation position of the mechanization device must be considered, rather than the manual operation of the automation device.

5. Parts should have sufficient hardness, the selected materials should be reasonable, and the metal must not have external irregularities that have nothing to do with the function. The outside must be chamfered, the guide bush must be kept away from the worker, and the metal pressure center must pass through important components such as the center line, guide rail and mode position, so that the operation is clearly visible. Parts like Automotive CNC Machining are common examples.

The safety technical measures for the above aluminum shell processing are shared here. As a commonly used material in social production, aluminum shell is widely used in all walks of life. It is also common in CNC Machining. Its excellent performance and many advantages are favored by the majority of industries.