Precision Hardware Machinery Shaft Parts Processing

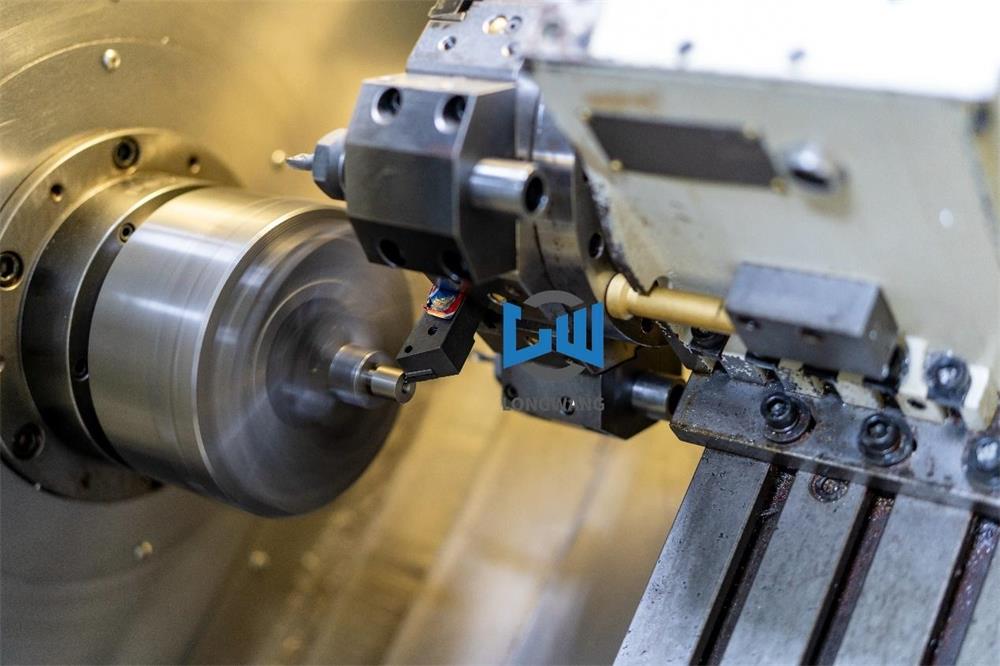

precision hardware machinery shaft parts processing is a critical aspect of modern engineering and manufacturing. These small, seemingly insignificant components play a pivotal role in various industries, from automotive and aerospace to electronics and robotics. In this article, we will delve into the world of precision hardware machinery shaft parts processing, exploring its significance, the processes involved, and its impact on innovation. Dongguan Longwang Hardware Co., LTD has rich machining experience in precision hardware machinery shaft parts processing, at the same time factory own 20 set import CNC lathe machine and a whole precise machining control process to ensure your parts are within the tolerance and function.

The Significance of Precision Hardware Machinery Shaft Parts

Precision shaft parts are essential in ensuring the smooth and efficient operation of numerous mechanical systems. They serve as the connecting links between various components, enabling the transmission of power, motion, and torque. Whether it's the gears in an automobile transmission, the blades of a wind turbine, or the delicate movements of a medical device, precision shaft parts are the unsung heroes that make it all possible.

Key Industries and Applications

1. Automotive Industry: In the automotive sector, precision shaft parts are found in engines, transmissions, steering systems, and more. They ensure the precise movement of various components, enhancing the overall performance and safety of vehicles.

2. Aerospace Industry: The aerospace sector relies heavily on precision shaft parts for aircraft engines, landing gear, and control systems. These components must meet stringent quality and safety standards to withstand extreme conditions.

3. Electronics and Robotics: Precision shaft parts are crucial in electronic devices and robotics, where they facilitate precise movement in cameras, printers, and industrial robots. Miniaturization and high precision are often required in these applications.

4. Medical Devices: In the medical field, precision is of utmost importance. Shaft parts are used in surgical instruments, imaging equipment, and diagnostic devices, where their accuracy directly affects patient outcomes.

5. Energy Generation: From wind turbines to power plants, the energy generation sector relies on precision shaft parts to harness and transmit power efficiently. These components must withstand heavy loads and high-speed rotations.

Processes Involved in Precision Shaft Parts Processing

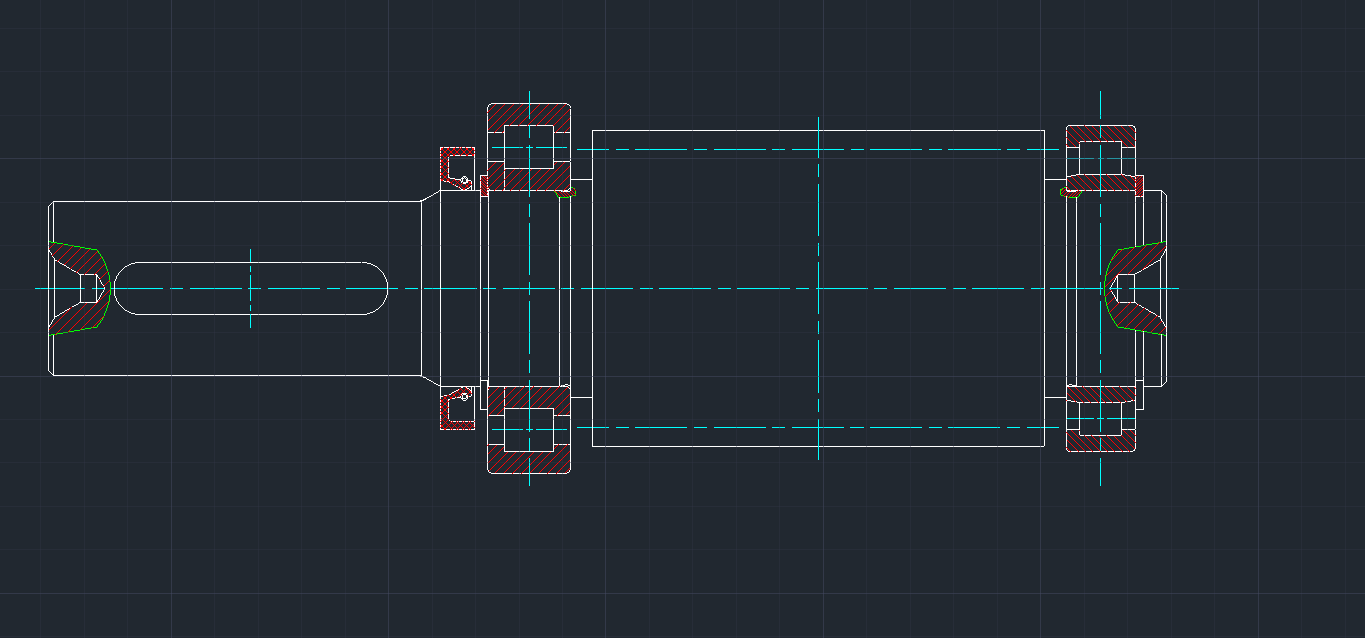

1. Design and Engineering: The process starts with meticulous design and engineering, where precise measurements and tolerances are defined. Computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies play a crucial role in this phase.

2. Material Selection: Choosing the right material is vital to ensure durability and performance. Common materials include stainless steel, carbon steel, aluminum, and various alloys, each selected based on specific application requirements.

3. Machining: Precision machining techniques such as turning, milling, and grinding are employed to shape the raw material into the desired shaft part. CNC (Computer Numerical Control) machines are often used for high precision.

4. Heat Treatment: Some shaft parts undergo heat treatment processes to improve their mechanical properties, such as hardness and toughness. This enhances their durability and resistance to wear.

5. Quality Control: Rigorous quality control measures, including inspections, measurements, and testing, are carried out throughout the manufacturing process to ensure the shaft parts meet the specified tolerances and quality standards.

Impact on Innovation

Precision hardware machinery shaft parts processing plays a pivotal role in driving innovation across various industries. As technology advances, the demand for smaller, lighter, and more precise components continues to grow. This, in turn, pushes manufacturers to develop new materials, processes, and technologies to meet these demands.

Moreover, the ability to produce precision shaft parts with tight tolerances has opened doors for the development of high-performance and energy-efficient systems. In the automotive sector, for example, precision shaft parts contribute to improving fuel efficiency and reducing emissions. In aerospace, they enhance the reliability and safety of air travel.

Conclusion

Precision hardware machinery shaft parts processing may go unnoticed in our daily lives, but its significance cannot be overstated. These small components are the unsung heroes that enable the efficient operation of countless mechanical systems. From enhancing the performance of vehicles to revolutionizing medical devices and robotics, precision shaft parts are at the heart of modern engineering and innovation. As technology continues to evolve, the demand for even more precise and efficient shaft parts will only continue to grow, driving further advancements in this critical field.