CNC Precision Machining for Medical Devices: Why Accuracy Saves Lives

The medical industry demands zero room for error. From surgical tools to life-saving implants, even the smallest deviation can compromise patient safety. At Dongguan Longwang Hardware, we specialize in CNC precision machining for medical devices, delivering components that meet stringent ISO 13485 and FDA standards. Here’s why CNC machining is indispensable in healthcare manufacturing.

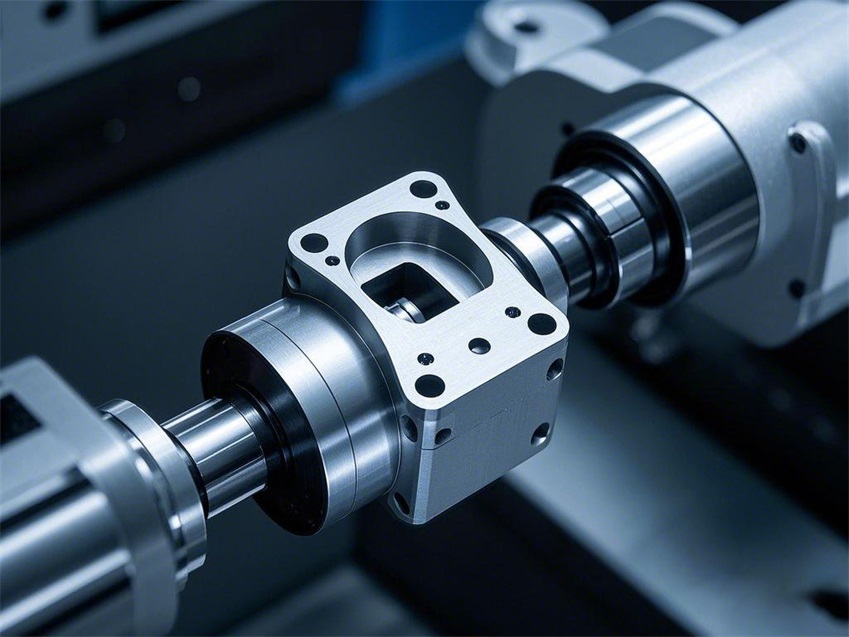

1. Critical Applications of CNC Machining in Healthcare

CNC technology produces components for:

· Surgical Instruments: Scalpels, forceps, and biopsy tools

· Implantable Devices: Titanium bone screws, spinal rods, and joint replacements

· Diagnostic Equipment: MRI machine parts, sensor housings, and fluidic systems

· Dental Components: Crowns, bridges, and orthodontic brackets

2. 5 Reasons Why CNC Dominates Medical Manufacturing

Factor | CNC Advantage |

Precision | Achieves tolerances as tight as ±0.005mm for leak-proof fluidic systems |

Material Versatility | Works with biocompatible metals (Ti6Al4V, 316L stainless steel) and engineering plastics (PEEK, UHMWPE) |

Surface Finish | Produces Ra <0.4μm surfaces to prevent bacterial adhesion |

Scalability | Consistent quality from prototypes to 10,000+ unit batches |

Regulatory Compliance | Full traceability with material certifications and process validation reports |

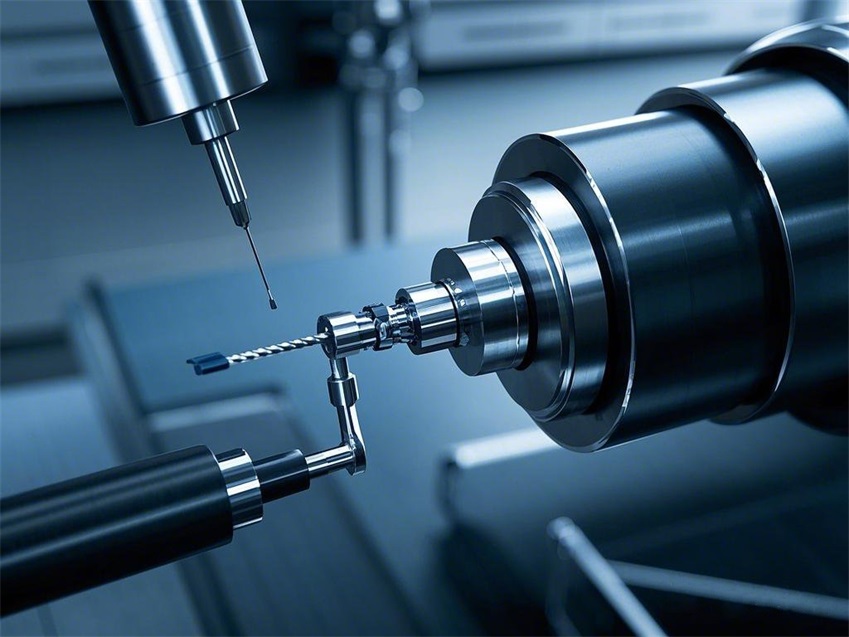

3. Case Study: Surgical Robotic Arms

A medical robotics company needed 200 aluminum actuator housings with:

· 0.02mm concentricity for seamless gear alignment

· Anodized surfaces for electrical insulation

· 3-day lead time for FDA trials

Our Solution:

· Used 5-axis CNC machines to achieve complex internal channels

· Implemented in-process CMM inspections every 50 units

· Delivered 100% compliant parts within 72 hours

4. Material Selection Guide for Medical CNC Parts

Material | Best For | Key Properties |

Titanium (Gr 5, Gr 23) | Implants, prosthetics | Biocompatible, high strength-to-weight |

316L Stainless Steel | Surgical tools, sterilization trays | Corrosion-resistant, autoclave-safe |

PEEK | Non-metallic implants, wear pads | Radiolucent, chemical resistance |

Aluminum 6061 | Diagnostic equipment housings | Lightweight, EMI/RFI shielding |

5. Quality Assurance at Longwang Hardware

We adhere to medical industry protocols through:

· 3D Scanning & CMM: Verifies dimensions against CAD models

· Post-Processing: Passivation, electropolishing, and ultrasonic cleaning

· Documentation: Material certs, RoHS compliance, and full batch traceability

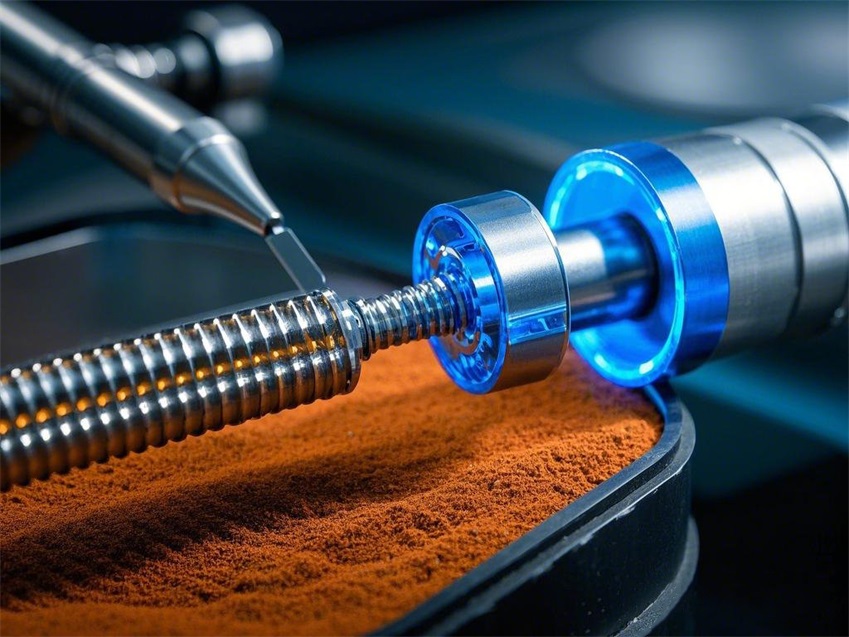

6. The Future: CNC Machining & Miniaturized Medical Devices

As devices shrink (e.g., microfluidic chips, nano-robots), our sub-micron CNC capabilities address trends like:

· Micro-milling: Features as small as 0.1mm

· Hybrid Manufacturing: Combining CNC with post-3D printing finishing

· Smart Factories: IoT-enabled machines for real-time quality monitoring

Why Choose Dongguan Longwang Hardware?

· 20+ years of medical CNC machining experience

· ISO 9001:2015 / IATF16949:2016 certified facility

· Prototype to mass production support

· Strict confidentiality agreements

Request a Free Medical Project Quotation!