CNC milling aluminum precision parts: the future of technology and application

In modern manufacturing, precision machining technology is undoubtedly the key to improving product quality and performance, and CNC milling, especially the machining of aluminum precision parts, has become an indispensable part of many industries. From aerospace to consumer electronics, to automobile manufacturing, aluminum is widely used in the production of various high-precision parts with its unique lightweight and high-strength characteristics, and CNC milling technology has become the preferred processing method in these industries with its excellent precision and efficiency.

Advantages of CNC milling: high precision and high efficiency

CNC milling can manufacture parts with complex shapes within the micron-level precision range, and the advantage of this precision is particularly prominent. For example, most of the fuselage structural parts of Boeing 787 are made of aluminum alloy materials, and the precision requirements of these parts are very high. CNC milling technology enables the dimensional accuracy of these aluminum alloy parts to reach ±0.1mm, ensuring the safety and structural stability of the aircraft. Such high precision and complexity can only be met by CNC milling, and it also reflects its great potential in precision engineering.

Not only that, CNC milling is also characterized by automation and high efficiency. Compared with traditional manual processing, CNC milling can greatly improve production efficiency and reduce errors caused by human operation. For example, the aluminum alloy body of the new generation of Audi A8 models widely uses CNC milling technology, which enables Audi to produce a large number of precision parts that meet strict standards in a short time. At the same time, through the high automation characteristics of computer numerical control technology, manual intervention and errors in the production process are greatly reduced, and production efficiency has been significantly improved.

Unique advantages of aluminum

As an ideal material for CNC milling, aluminum is the first choice for many industries due to its light weight, high strength and good processing performance. In the automotive and aerospace fields, the application of aluminum not only effectively reduces the weight of the overall structure, but also improves the strength of parts. For example, the aluminum alloy body of the BMW X series is manufactured by CNC milling. This lightweight design brings higher fuel efficiency and better driving performance to the vehicle.

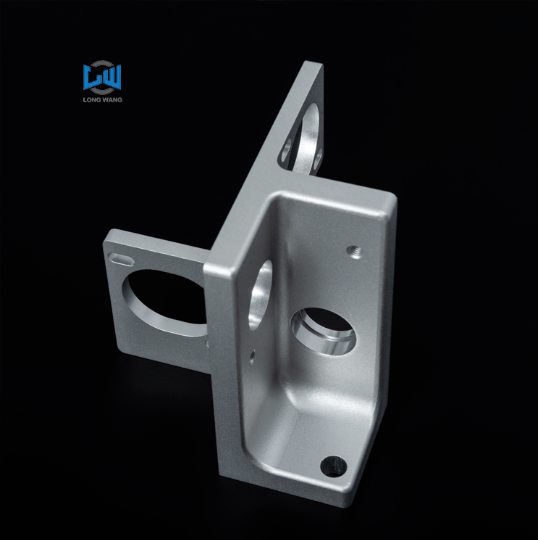

The easy processing of aluminum alloy also makes it occupy an important position in the manufacture of precision parts. Whether it is complex geometric shapes or subtle apertures and cuts, CNC milling can accurately reproduce every detail of the design drawings. Moreover, aluminum has strong corrosion resistance. In electronic product housings, medical devices, and various consumer electronic devices, the application of aluminum alloy precision parts can effectively extend the service life of products.

Technical Challenges and Solutions

However, the processing of aluminum alloys is not without challenges. In the CNC milling process, tool wear and heat generated during processing often affect processing accuracy and production efficiency. Take BMW as an example. In the production process of aluminum alloy body parts, "PCD (polycrystalline diamond)" tools are used. This tool material not only improves the processing accuracy of aluminum alloy parts, but also greatly extends the service life of tools. Data shows that after using PCD tools, BMW's aluminum alloy parts processing accuracy has increased by about 10%, and tool life has been extended by more than 50%.

In addition, the cutting heat of aluminum also needs to be effectively controlled. By optimizing the coolant system and cutting parameters, the heat generated during the cutting process can be effectively reduced, thereby avoiding the negative impact of overheating on part quality and tool life.

Expansion of application areas: from aviation to electronics

The application areas of CNC milling aluminum precision parts are very wide, covering aerospace, automobile manufacturing, consumer electronics and other industries. In the aerospace industry, precision aluminum alloy parts require not only high precision, but also strong pressure resistance and corrosion resistance. The aluminum alloy fuselage and wing parts of the Airbus A350 are manufactured through high-precision CNC milling. The entire production process requires the component tolerance to be controlled within ±0.05mm, ensuring the safety and stability of the aircraft.

In the field of consumer electronics, CNC milling technology also has important applications. For example, Apple's iPhone shell is processed by CNC milling. The precision of the iPhone's aluminum alloy shell can reach ±0.02mm, which ensures the perfect match of the shell and high-quality surface effects. Apple also further improves the corrosion resistance and aesthetics of the shell through surface treatment processes such as anodizing.

Future development: intelligent manufacturing and green processing

With the continuous development of science and technology, CNC milling technology is also constantly improving. General Electric (GE) Aviation has introduced intelligent manufacturing technology and used AI and machine learning algorithms to optimize tool paths and processing parameters, which not only improved production efficiency, but also significantly improved the processing accuracy and quality of turbine blades. The application of intelligent manufacturing technology indicates that CNC milling is moving towards higher automation and intelligence.

In addition, with the increasing awareness of environmental protection, green manufacturing has become an important development direction for the future manufacturing industry. Reducing waste, improving resource utilization and reducing energy consumption will be important development trends in CNC milling technology in the future. By adopting environmentally friendly materials and optimizing processing technology, manufacturers can not only improve production efficiency but also reduce the impact on the environment.

Conclusion

As a core technology in modern manufacturing, CNC milling of aluminum precision parts has achieved remarkable application results in many fields. From aerospace to consumer electronics, to the automotive and medical industries, CNC milling technology has promoted the development of many industries with its high precision, high efficiency and good processing performance. In the future, with the continuous development of intelligent manufacturing and green processing technology, CNC milling will usher in a broader application prospect and provide technical support for the realization of a more efficient and environmentally friendly manufacturing industry.