CNC Machining And Its Advantages And Disadvantages

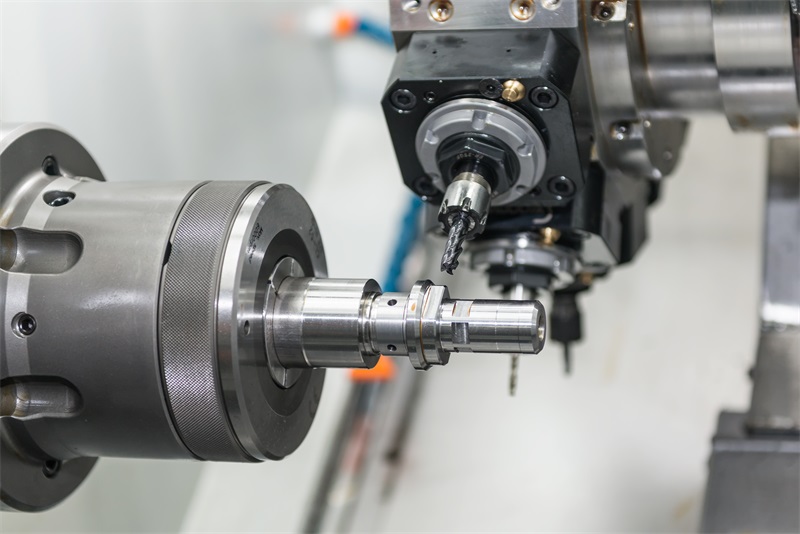

In fact, it is a CNC milling machine, which is an automatic machine tool equipped with a program control system. The control system can logically process the program specified by the control code or other symbolic instructions, and decode it through the computer, so as to make the machine tool move and process the parts. The rough material is processed into semi-finished finished parts, etc. by tool cutting.

CNC machining, CNC machining refers to the machining performed with CNC machining tools. CNC index-controlled machine tools are programmed and controlled by CNC machining language, usually G code. The CNC machining G code language tells the CNC machine tool which Cartesian position coordinates the machining tool adopts, and controls the feed rate and spindle speed of the tool, as well as functions such as tool changer and coolant. CNC machining has great advantages over manual machining. For example, the parts produced by CNC machining are very accurate and repeatable; CNC machining can produce parts with complex shapes that cannot be completed by manual machining. CNC machining technology has been widely promoted, and most machining workshops have CNC machining capabilities. The most common CNC machining methods in typical machining workshops are CNC milling, CNC turning and CNC EDM wire cutting (EDM wire cutting). The tools for CNC milling are called CNC milling machines or CNC machining centers. A lathe that performs CNC turning is called a CNC turning center. CNC machining G codes can be programmed manually, but usually machine shops use CAM (Computer Aided Manufacturing) software to automatically read CAD (Computer Aided Design) files and generate G code programs to control CNC machine tools.

CNC machining has the following advantages:

① The number of tooling is greatly reduced, and complex tooling is not required to process parts with complex shapes. If you want to change the shape and size of the part, you only need to modify the part processing program, which is suitable for new product development and modification.

②Stable processing quality, high processing precision and high repeatability, which can meet the processing requirements of aircraft.

③ The production efficiency is high in the case of multi-variety and small batch production, which can reduce the time for production preparation, machine tool adjustment and process inspection, and reduce the cutting time due to the use of the optimal cutting amount.

④ It can process complex profiles that are difficult to process by conventional methods, and even process some unobservable processing parts.

The disadvantage of CNC machining is that the machine tool is expensive and requires a high level of maintenance personnel.We have CNC machining for parts machining of different materials, custom and wholesale. Support steel machining. In order to pursue diversification, we also have CNC keyboard processing, you can consult us for more details.