13 Key Points To Prevent Welding Deformation!

Welding is a hot working process, and welding deformation is ubiquitous in the welding process, which is one of the main problems affecting the quality and productivity of welded structures. The existence of welding deformation not only affects the manufacturing process of welded structures, but also affects the use performance of welded structures. It is generally believed that the non-uniform heating of materials, the thermal gradient in the direction of plate thickness, the local incompatible plastic strain of materials and the role of welding residual stress are the fundamental reasons for various welding deformations. There are several methods to prevent welding deformation.

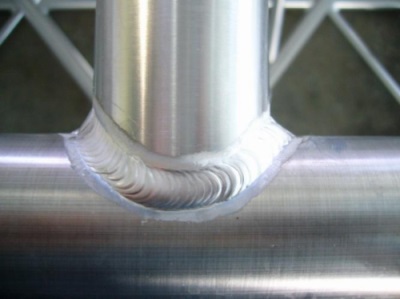

1. Reduce the sectional area of the weld, and use smaller groove size (angle and gap) as far as possible on the premise of obtaining complete weld without exceeding standard defects.

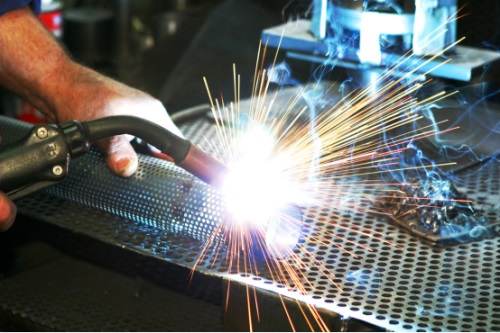

2. Welding method with small heat input is adopted. Such as CO2 gas shielded welding.

3. For thick plate welding, multi-layer welding shall be used instead of single-layer welding as far as possible.

4. On the condition that the design requirements are met, the welding of longitudinal stiffeners and transverse stiffeners can adopt the discontinuous welding method.

5.When both sides can be welded, double-sided symmetric groove shall be used, and the welding sequence which is symmetrical to the component and axis shall be used in multi-layer welding.

6. When the thickness of T-shaped joint is large, bevel fillet butt weld shall be used.

7. The anti deformation method before welding is adopted to control the angular deformation after welding.

8. The rigid fixture fixing method is used to control the deformation after welding.

9. The reserved length of the component is used to compensate the longitudinal shrinkage deformation of the weld. For example, 0.5~0.7mm can be reserved per meter for H-shaped longitudinal weld.

10. Twist for long components. The groove angle and clearance are accurate mainly by improving the flatness of the plate and the assembly accuracy of the components. The direction or centering of the arc is accurate, so that the angular deformation of the weld and the longitudinal deformation of the flange and web are consistent with the length direction of the component.

11. In the assembly welding of components with more welds or structural installation, reasonable welding sequence shall be adopted.

12. When welding thin plates, use the underwater welding method. Namely, the molten pool is surrounded by protective gas in the water, and the nearby water is completely discharged by the gas to ensure normal welding. With this method, the metal around the solid weld pool is timely cooled by water, while the deformation is controlled to a very small extent (add circulating coolant on the opposite side of the welding side to take away the heat generated by welding).

13.Multi section symmetrical welding, that is, welding one section, and stopping for a while, welding on the opposite side, stopping for a while.

Dongguan Longwang Hardware Co.,Ltd have more than 13 years experience in sheet metal fabrication and CNC machining service,professional machining team and engineer team can slove the tough nut to crack. If you have any demand of sheet metal fabrication,stamping,bending and cnc machining,please contact with us.