Understanding CNC Milling Machines: A Masterful Blend of Precision and Automation

Introduction

In the realm of manufacturing and engineering, CNC (Computer Numerical Control) milling machines have become an indispensable tool, revolutionizing the way complex parts and components are crafted with precision. These machines combine cutting-edge technology and automation to streamline the manufacturing process and deliver consistent and accurate results. This article aims to explore what CNC milling machines are and delve into the intricacies of how they work.

What is a CNC Milling Machine?

A CNC milling machine is a powerful and versatile tool used in the manufacturing industry to create intricate and precise parts from various materials, including metals, plastics, and wood. The primary difference between a conventional milling machine and a CNC milling machine lies in their mode of operation. While a conventional milling machine requires manual control, a CNC milling machine operates under computer numerical control, where pre-programmed software dictates its movements.

How Does a CNC Milling Machine Work?

Computer-Aided Design (CAD):

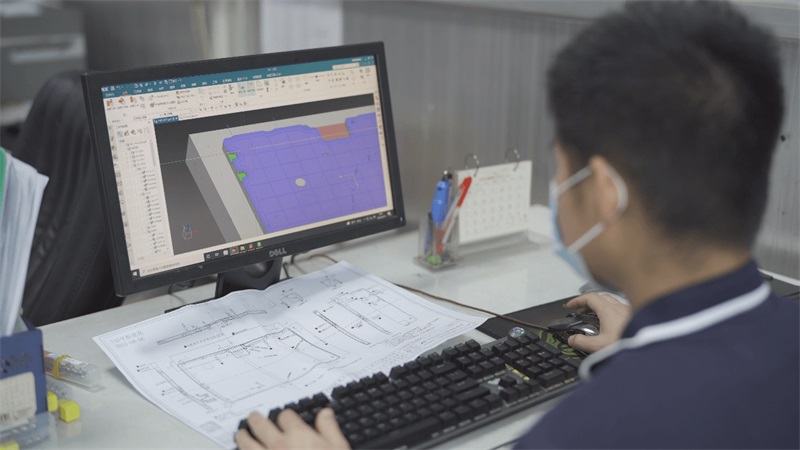

The process begins with the creation of a detailed digital model of the desired part using Computer-Aided Design (CAD) software. Engineers or designers create a 2D or 3D model that serves as the blueprint for the CNC machine to follow. The CAD software generates the necessary code in the form of G-code, which contains instructions for the CNC machine's movements.

CAM Software:

The generated G-code is then imported into Computer-Aided Manufacturing (CAM) software. CAM software plays a crucial role in converting the design into a set of instructions that the CNC machine can understand. It optimizes toolpaths, calculates cutting speeds, and ensures the efficient removal of material, taking into account the chosen material and desired precision.

Machine Setup:

Once the G-code is ready, an operator loads it into the CNC milling machine's control unit. The material to be machined, such as a metal block or a sheet of plastic, is securely clamped onto the machine's worktable. The cutting tool, usually an end mill or drill bit, is selected based on the material and design specifications.

Cutting Process:

With the material in place and the tool properly set up, the CNC milling machine is ready to commence the cutting process. The operator initiates the operation, and the CNC controller reads the G-code line by line, commanding the machine's movements along the X, Y, and Z axes.

The X-axis represents the horizontal movement of the table, the Y-axis denotes the vertical movement of the spindle, and the Z-axis controls the depth of the cut. Advanced CNC machines may also have additional axes for more complex operations.

Automated Precision:

As the CNC machine follows the instructions from the G-code, the cutting tool engages the material, gradually removing excess material layer by layer. The precise and automated movements of the CNC machine ensure consistent results and eliminate the human error factor.

Coolant and Chip Management:

During the milling process, the friction between the cutting tool and the material generates heat and chips. To prevent overheating and maintain cutting efficiency, a coolant (usually a liquid or air) is often applied. Additionally, chip management systems remove the waste material from the work area to maintain a clear cutting path.

Finishing Touches:

Once the CNC milling machine completes the cutting process, the finished part may undergo further post-processing, such as deburring, polishing, or coating, depending on the application and desired end-product quality.

Conclusion

CNC milling machines have significantly transformed the manufacturing landscape by offering unmatched precision, repeatability, and efficiency. Through the synergy of computer programming, automation, and advanced cutting tools, these machines have become the backbone of numerous industries, enabling the creation of complex and intricate parts with unparalleled accuracy. As technology continues to advance, CNC milling machines will undoubtedly play an even more pivotal role in shaping the future of manufacturing.

Dongguan Longwang is a CNC machining factory is a sophisticated and efficient production facility that leverages CNC technology, skilled personnel, and quality control measures to manufacture precise and intricate parts and components for a diverse range of industries. Quality control is a critical aspect of our CNC machining factories. Throughout the production process, rigorous inspections and tests are conducted to ensure that the finished products adhere to the required specifications and tolerances. This ensures that the final output is of consistent high quality.

If you have any project need quotation, please contact us!