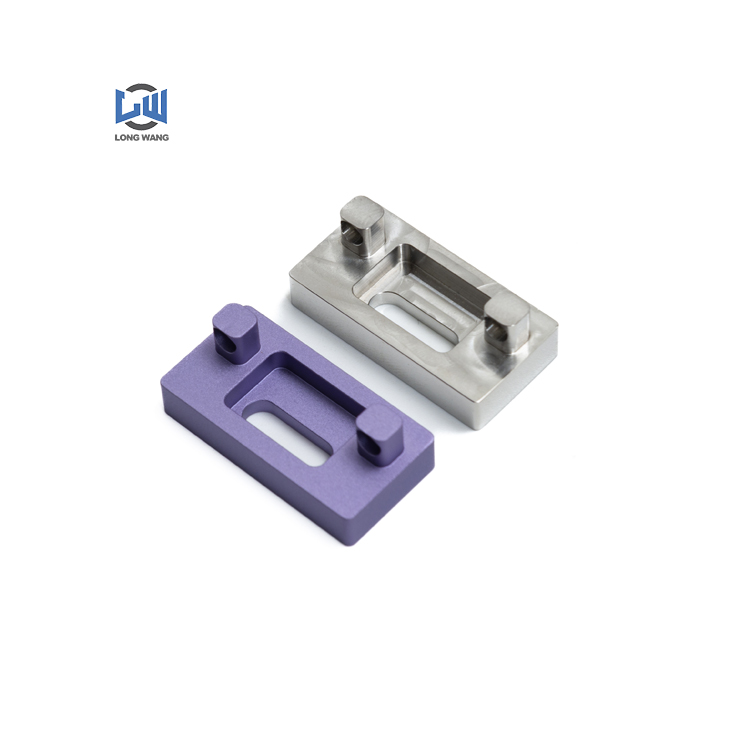

High Tolerance CNC Machining CNC Part Manufacturer

High Tolerance CNC Machining CNC Part Manufacturer

As experts in high-tolerance CNC machining, we specialize in manufacturing precision parts that meet the most stringent dimensional and geometric tolerances. Leveraging advanced CNC technology and rigorous quality control, we ensure every component is crafted to the highest industry standards, serving various demanding applications from aerospace to medical devices.

Our skilled team offers tailored solutions to meet specific customer needs, handling complex geometries and micron-level tolerances with precision. We are committed to exceeding expectations with superior craftsmanship and consistent quality. Choose us for high-precision CNC parts and exceptional service, and let us support your success with reliable and efficient solutions.

Key Features

Precision Machining

Utilizes advanced CNC technology to ensure each part meets stringent dimensional and geometric tolerances for the highest precision.

High Tolerance Standards

Specializes in high-tolerance manufacturing, handling complex geometries and micron-level tolerances to ensure consistent and reliable product quality.

Advanced Equipment

Equipped with state-of-the-art CNC machining equipment, supporting efficient and precise processing of various materials, enhancing production capability.

Custom Solutions

Offers tailored machining services to meet specific customer requirements, adapting to various industry applications and technical needs.

Rigorous Quality Control

Implements a comprehensive quality management system, with strict inspections at every stage from material procurement to final product, ensuring compliance with international standards.

Experienced Team

Boasts a team of seasoned engineers and technicians providing professional advice and solutions based on extensive industry experience, ensuring project success.

Applications

Aerospace Industry

Provides high-precision components for aircraft and spacecraft systems, including engine parts, structural components, and navigation devices, ensuring reliability and performance under extreme conditions.

Medical Devices

Manufactures precision parts for medical instruments, such as surgical tools, diagnostic equipment, and implants, meeting stringent hygiene standards and high precision requirements for safety and accuracy.

Automotive Industry

Supplies high-tolerance components for engines, transmissions, and suspension systems, enhancing vehicle performance and durability to meet rigorous industry standards.

Electronic Devices

Produces precision parts for computers, communication equipment, and consumer electronics, such as connectors, enclosures, and internal components, improving device reliability and functionality.

Industrial Machinery

Manufactures high-precision components for various machinery, including automation equipment, production line tools, and precision instruments, enhancing machinery performance and production efficiency.

Energy Sector

Produces critical components for oil, gas, and renewable energy systems, ensuring stability and reliability in high-pressure and high-temperature environments.

Advantages of Using High Tolerance CNC Machining CNC Part Manufacturer

Exceptional Precision and Consistency

High-tolerance CNC machining ensures uniformity in dimensions and geometries, meeting the strictest precision requirements, enhancing the overall performance and reliability of the product.

Flexible Customization

Provides tailored solutions according to specific customer needs and industry standards, accommodating various complex design requirements and technical specifications.

Efficient Production Capacity

Advanced CNC equipment supports large-scale production while maintaining high precision, reducing lead times to meet urgent manufacturing needs.

Superior Materials and Craftsmanship

Utilizes high-quality materials and meticulous machining processes to ensure durability and long-term stability of components, suitable for high-demand applications.

Strict Quality Control

Implements a comprehensive quality management system from material procurement through production to final inspection, ensuring components meet international standards and reducing defect rates.

Professional Technical Support

Boasts a team of experienced engineers and technicians offering expert advice and support, addressing design and machining challenges to enhance project success.

Reduced Maintenance Costs

High-precision components minimize system failures and maintenance needs, lowering long-term maintenance costs and improving overall operational efficiency.