Exploring Sheet Metal Processing Parts Processing

Sheet metal processing is a fundamental manufacturing technique used across industries to create a wide range of components and products. From simple brackets to complex enclosures, sheet metal processing plays a crucial role in shaping modern manufacturing. In this article, we will delve into the world of sheet metal processing parts processing, exploring its techniques, applications, and significance in today's industrial landscape.

Understanding Sheet Metal Processing:

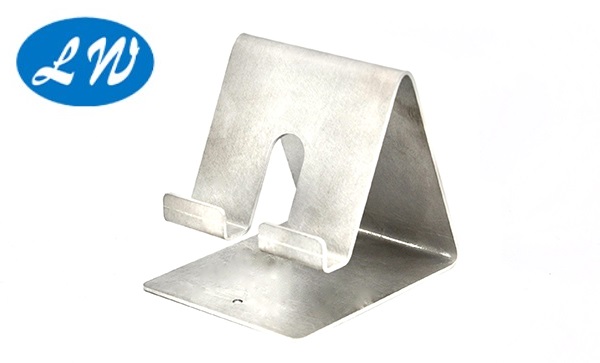

Sheet metal processing involves the fabrication of metal sheets into desired shapes and forms through various techniques such as cutting, bending, stamping, and welding. These processes allow manufacturers to transform flat sheets of metal, typically steel, aluminum, or stainless steel, into intricate components with precise dimensions and tolerances.

Techniques Used in Sheet Metal Processing:

1.Cutting: Cutting is the first step in sheet metal processing, where large sheets of metal are cut into smaller, more manageable pieces using techniques such as shearing, laser cutting, or plasma cutting.

2.Bending: Bending involves the deformation of metal sheets along a straight axis to create angles, curves, or complex shapes. Press brakes or rollers are commonly used to bend metal sheets to the desired angle or radius.

3.Stamping: Stamping is a process where a metal sheet is placed in a die and subjected to high pressure to create specific shapes or features. This technique is commonly used to produce parts with consistent dimensions and intricate details.

4.Welding: Welding is used to join metal sheets together, either through fusion welding techniques such as MIG or TIG welding, or through mechanical fastening methods like riveting or spot welding.

Applications of Sheet Metal Processing Parts:

Sheet metal processing parts find applications across a wide range of industries, including:

1.Automotive: Sheet metal parts are used extensively in the automotive industry for body panels, chassis components, and structural reinforcements.

2.Electronics: Sheet metal enclosures and housings are commonly used in electronic devices and appliances to protect sensitive components and provide structural support.

3.Aerospace: The aerospace industry relies on sheet metal processing for manufacturing aircraft components, such as fuselage sections, wing structures, and engine housings.

4.Construction: Sheet metal parts are used in construction for roofing, cladding, structural framing, and HVAC systems.

Significance of Sheet Metal Processing:

Sheet metal processing offers several advantages, including:

1.Cost-Effective Production: Sheet metal processing allows for high-volume production of parts at relatively low cost, making it economical for mass manufacturing.

2.Versatility: Sheet metal processing techniques can be applied to a wide range of materials and thicknesses, offering versatility in design and fabrication.

3.Precision and Accuracy: Advanced machinery and computer-aided design (CAD) software enable precise and accurate fabrication of complex parts with tight tolerances.

4.Strength and Durability: Sheet metal parts are known for their strength, durability, and resistance to corrosion, making them suitable for demanding applications in various industries.

Sheet metal processing parts processing is a versatile and essential manufacturing technique that underpins many industries. From automotive and aerospace to electronics and construction, sheet metal parts play a vital role in modern manufacturing. By understanding the techniques, applications, and significance of sheet metal processing, manufacturers can harness its potential to create high-quality components and products that meet the demands of today's marketplace.