CNC Machining To Create A High-Quality Keyboard

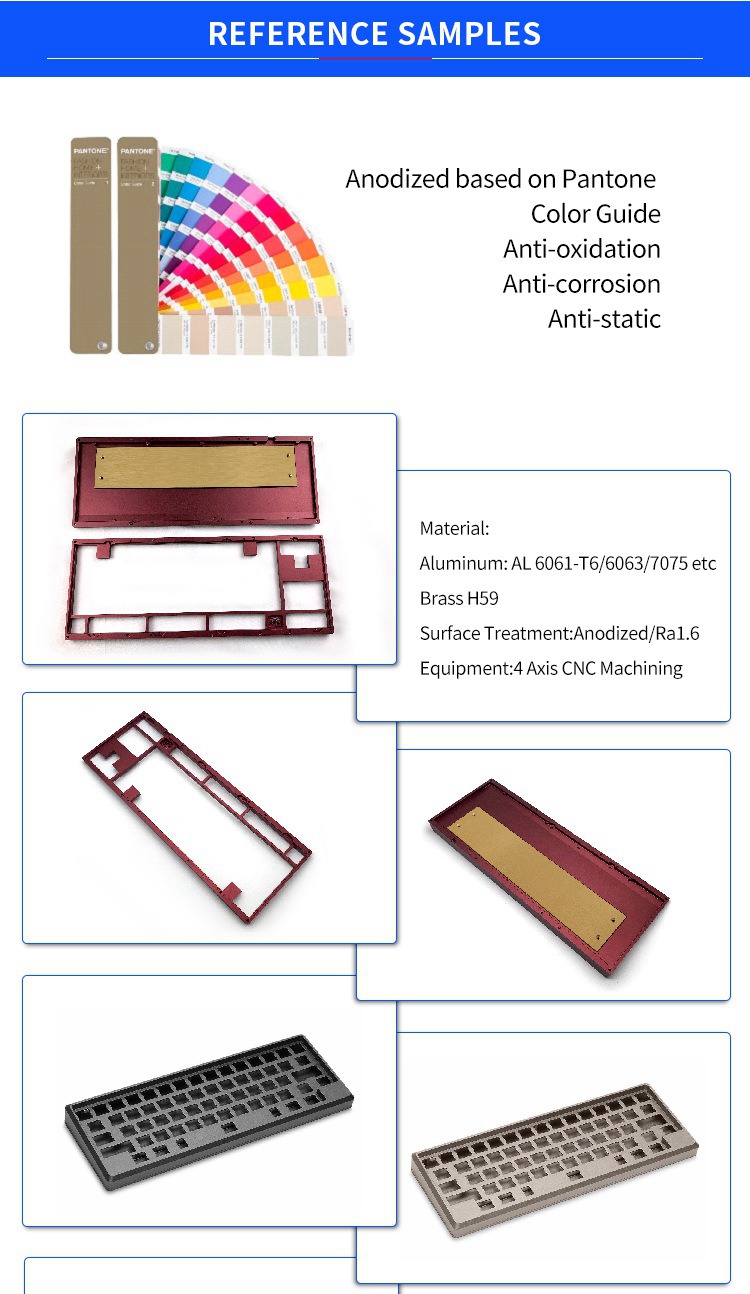

Customized CNC machining aluminum game keyboard kit;

Machined based on your own design and logo;

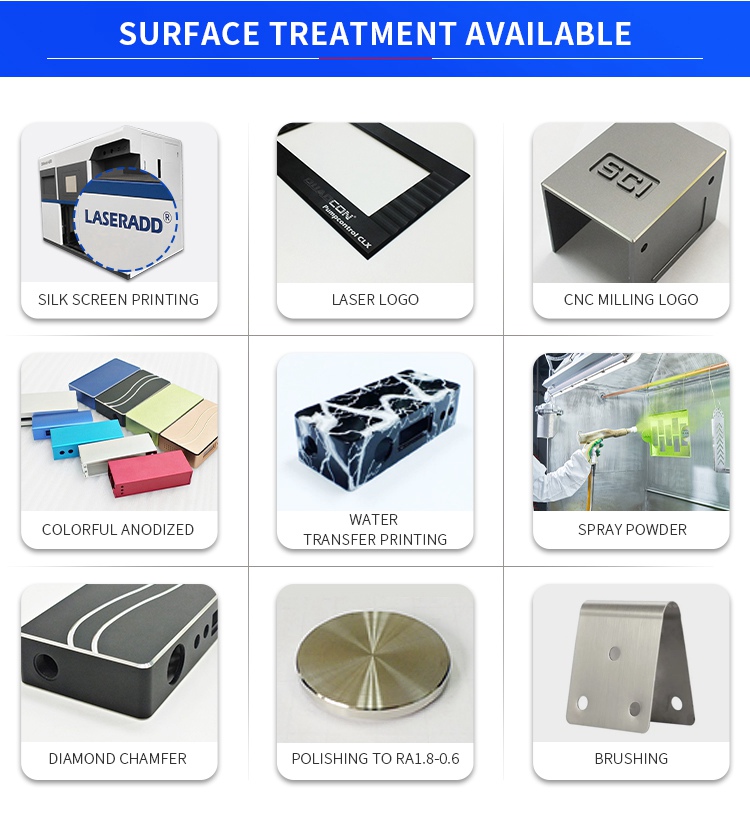

Different surface treatment for your different color requirement;

Color based on Pantone Color Guide;

Material is the same quantity standard with iphone's.

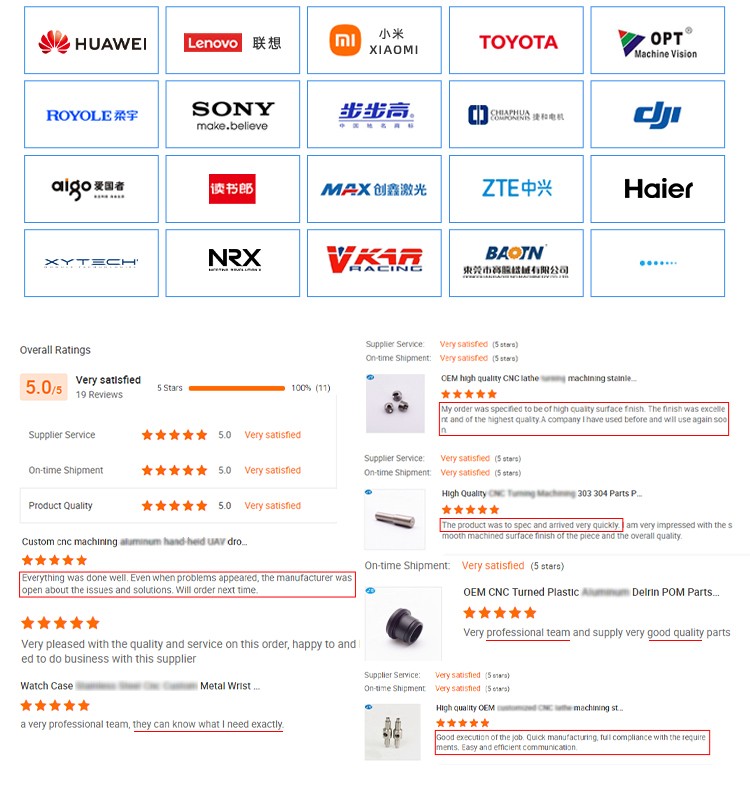

We support a variety of optional specifications, and the processing of drawings can be reasonably customized according to the requirements of customers. We support customized processing of incoming materials and samples, and customized keyboard cnc machining aluminum. We are a word-of-mouth manufacturer, you can choose with confidence and provide customers with high-quality prices.

We specialize in custom machining of CNC lathe machining parts, such as custom aluminum keyboard. Professional hepatitis A function long. An innovative technical company that provides hardware machinery parts and non-standard parts processing, while taking into account product design and development. A variety of processing techniques and different materials can be processed.

High-quality aluminum keyboard board cnc machining, accessories for display stands, production and maintenance of precision parts, metal processing, post-processing of castings, toolbox accessories, auto parts, etc., all support processing, as long as you need it, you can contact us us.

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T, etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1, TA2/GR2, TA4/GR5, TC4, TC18, etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM, Acrylic, PC, etc. | |

| Finish | Sandblasting, Anodized color, Blackening, Zinc/Nickl Plating, Polish, |

| Powder coating, Passivation PVD, Titanium Plating, Electro galvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing, Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling Machine, Laser Cutting Machine, etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

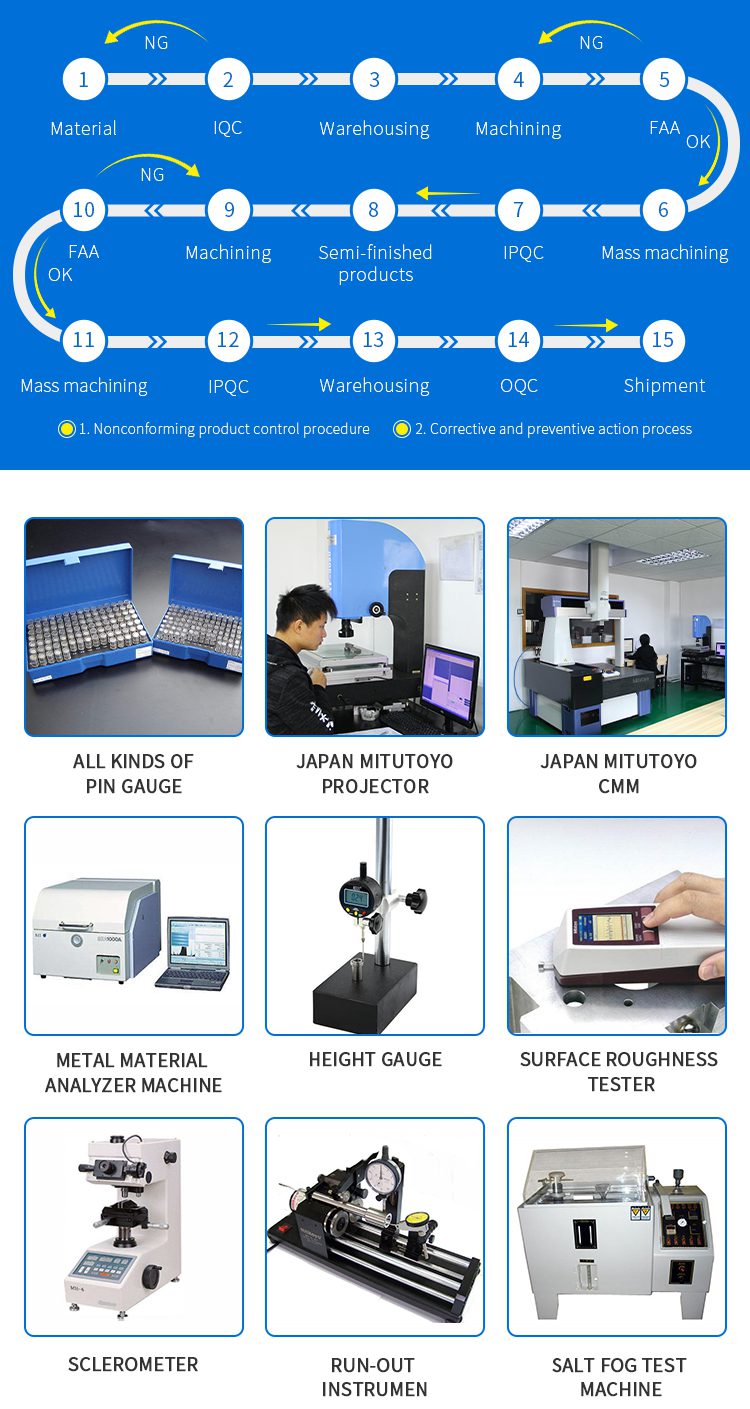

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier, CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |

Related Products

Submitted successfully

We will contact you as soon as possible