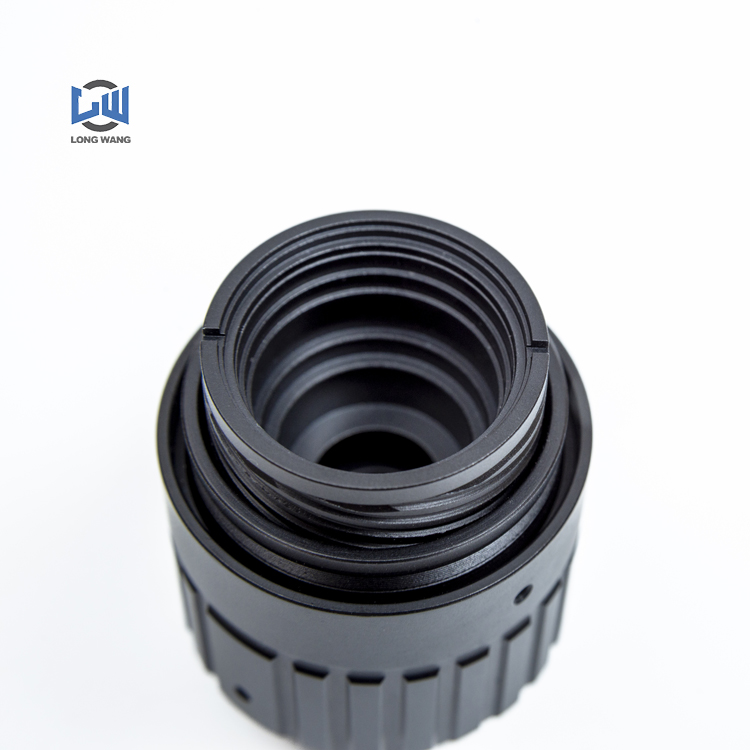

CNC Machining Precision Aluminum Camera Parts

CNC turning & CNC Milling machining aluminum vision equipment parts

Customized anodized color based on your requirements

Reduce costs and delivery times

Efficient and flexible production processes

5-axis CNC machining helps save more time than other traditional types. Most parts manufactured in CNC workshops must be machined on five surfaces. 5-axis CNC machining helps to efficiently and quickly complete work in production. In a 5-axis machining machine, the position of the parts is relatively close to the cutting tool. The last two axes will allow the use of short tools with less vibration, which will significantly affect the quality of the surface finish. 5-axis machining reduces several inaccuracies in traditional 3-axis machining by reducing part processing, thereby minimizing the cost of each part. It can also extend tool life and reduce the demand for expensive fixtures. When using a 3-axis machine tool, longer delivery times are required due to the long setup time required.

Service industries: aerospace, automotive industry, national defense, food processing, forging, casting, heavy equipment, infrastructure, marine, medical equipment, military, mining, oil and gas, power generation, space | rockets, and transportation.

Five-axis machining centers, as highly automated intelligent processing equipment, are commonly used in high-end manufacturing. The five-axis machining center is suitable for processing free-form surface parts, turbine parts, and impellers on aircraft and ships. We can find that workpieces suitable for machining on a five-axis machining center have the characteristics of high surface roughness and difficulty in forming during one-time clamping. Therefore, a five-axis machine tool can process different sides of the workpiece without changing its position on the machine. Improve the processing efficiency of prismatic parts.

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T, etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1, TA2/GR2, TA4/GR5, TC4, TC18, etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM, Acrylic, PC, etc. | |

| Finish | Sandblasting, Anodized color, Blackening, Zinc/Nickl Plating, Polish, |

| Powder coating, Passivation PVD, Titanium Plating, Electro galvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing, Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling Machine, Laser Cutting Machine, etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier, CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |