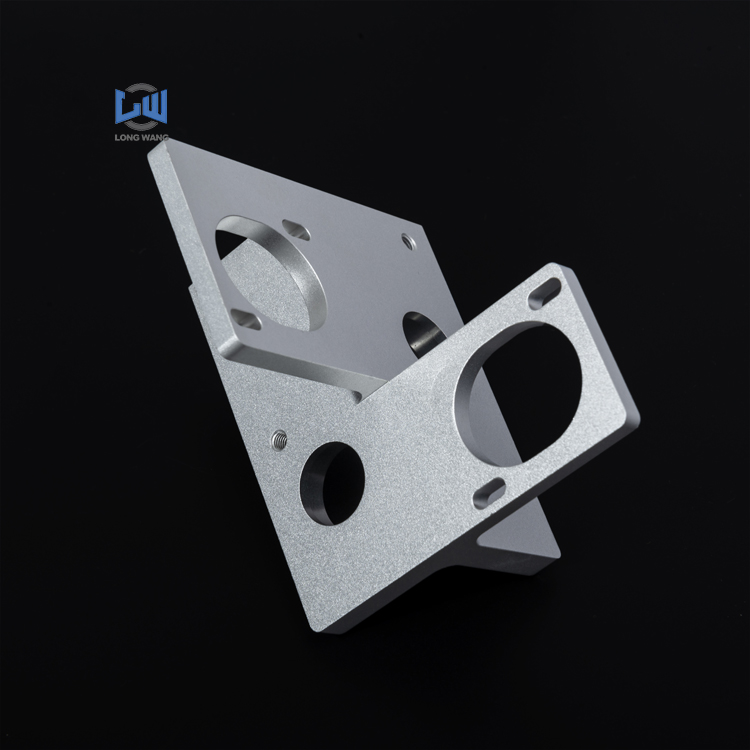

CNC Machining Precision Aluminum Machined Metal Parts

Category: CNC parts precision machining

Product Name: Military Cavity

Processing method: CNC machining aluminum precision parts

Material: aluminum alloy

Surface treatment: polishing, deburring, oxidation

Processing cycle: 3-7 seven working days

Test standard: 3D drawings provided by the customer

Data format: STP/IGS/X.T/PRO/DWG

Product features: smooth surface, high gloss, and fine workmanship

In CNC parts precision machining, the design of the part is created using computer-aided design (CAD) software. This design is then translated into a set of instructions for the CNC machine using computer-aided manufacturing (CAM) software. The instructions are sent to the machine's controller, which controls the movement of the cutting tool and the positioning of the workpiece in order to create the desired shape.

CNC parts precision machining can be used to produce a wide variety of parts, from small and simple components to large and complex assemblies. The process can be used to create parts with intricate shapes and features, such as holes, threads, and contours, with high precision and accuracy.

One of the key advantages of CNC parts precision machining is its ability to produce parts with consistent quality and dimensional accuracy. This is especially important in industries such as aerospace and medical, where even small variations in part dimensions can have a significant impact on performance and safety.

Overall, CNC parts precision machining is a highly advanced and versatile manufacturing process that is widely used in a variety of industries to produce high-quality, precise parts with tight tolerances and consistent quality.

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T, etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1, TA2/GR2, TA4/GR5, TC4, TC18, etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM, Acrylic, PC, etc. | |

| Finish | Sandblasting, Anodized color, Blackening, Zinc/Nickl Plating, Polish, |

| Powder coating, Passivation PVD, Titanium Plating, Electro galvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing, Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling Machine, Laser Cutting Machine, etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier, CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |