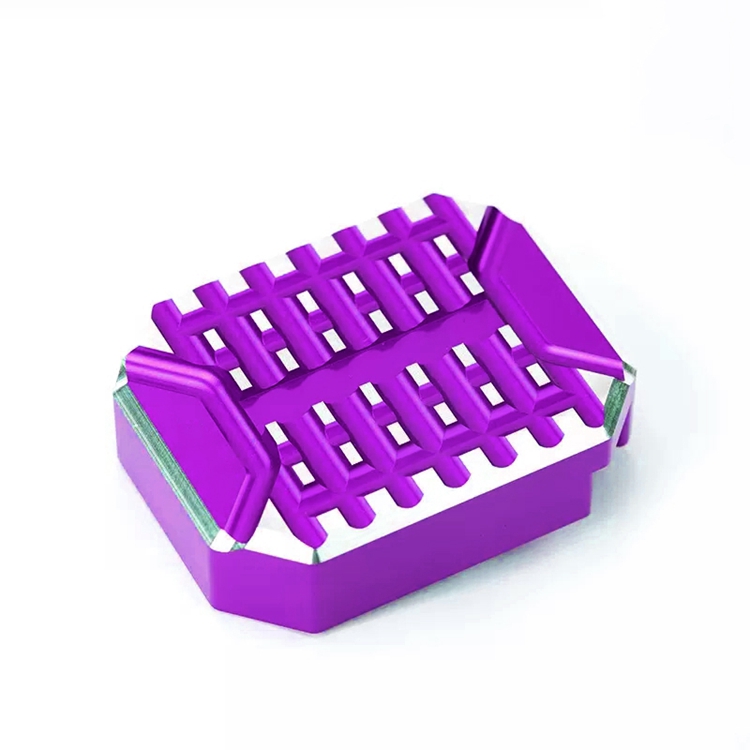

CNC Machining Bicycle Pedals Aluminum Alloy CNC Purple

Stable quality - strictly adhering to ISO quality standards, with the help of internal precision measurement and testing equipment (CMM, projector, etc.), we can inspect all incoming materials and parts to meet your specifications. We will provide an inspection report before shipment.

Strong production capacity - nearly a hundred CNC machine tools can withstand large-scale production

Rapid production - providing reliable CNC quick prototype solutions

High quality service - communicate production progress with customers in a timely manner and deliver on time

The importance of product quality and accuracy for precision parts processing manufacturers is self-evident. In the production process, it is particularly important to pay attention to the details. Small details determine success or failure. Not only should we have the spirit of craftsmanship, but we should also truly achieve precision machining and make our good products. If the product cannot meet the customer's precision requirements, the market will mercilessly eliminate us.

Specifically, there are some concepts in precision part machining drawings that make us more familiar with dimensions, deviations, and dimensional tolerances. We should keep in mind the levels of general unmarked linear and angular tolerances, as well as the levels of general unmarked shape and positional tolerances.

The elements of dimensioning in drawings, such as diameter dimensions, diameters, and semicircles, dimensions with square structures, chamfers, threads, smooth holes, countersunk holes, threaded holes, and grooves, as well as chain dimensioning with equal spacing, have given us a further comprehensive understanding of the drawings. Text and drawing examples allow us to learn more intuitively, and combined with practical examples in work, we can improve the quality of the products.

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T, etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1, TA2/GR2, TA4/GR5, TC4, TC18, etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM, Acrylic, PC, etc. | |

| Finish | Sandblasting, Anodized color, Blackening, Zinc/Nickl Plating, Polish, |

| Powder coating, Passivation PVD, Titanium Plating, Electro galvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing, Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling Machine, Laser Cutting Machine, etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier, CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |