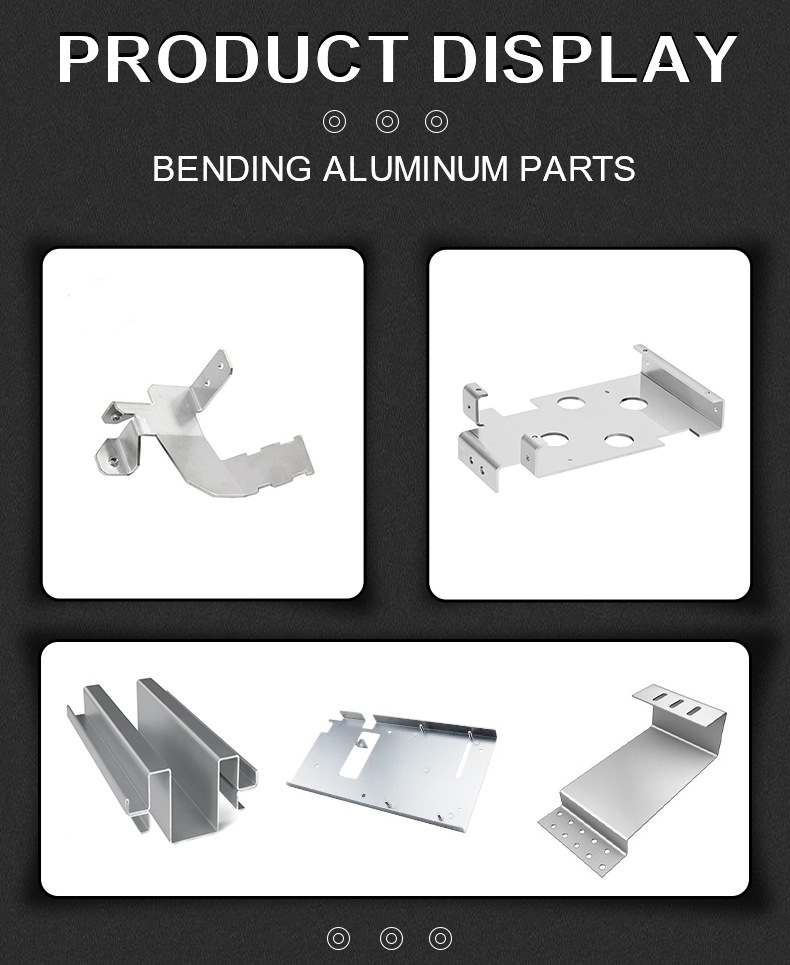

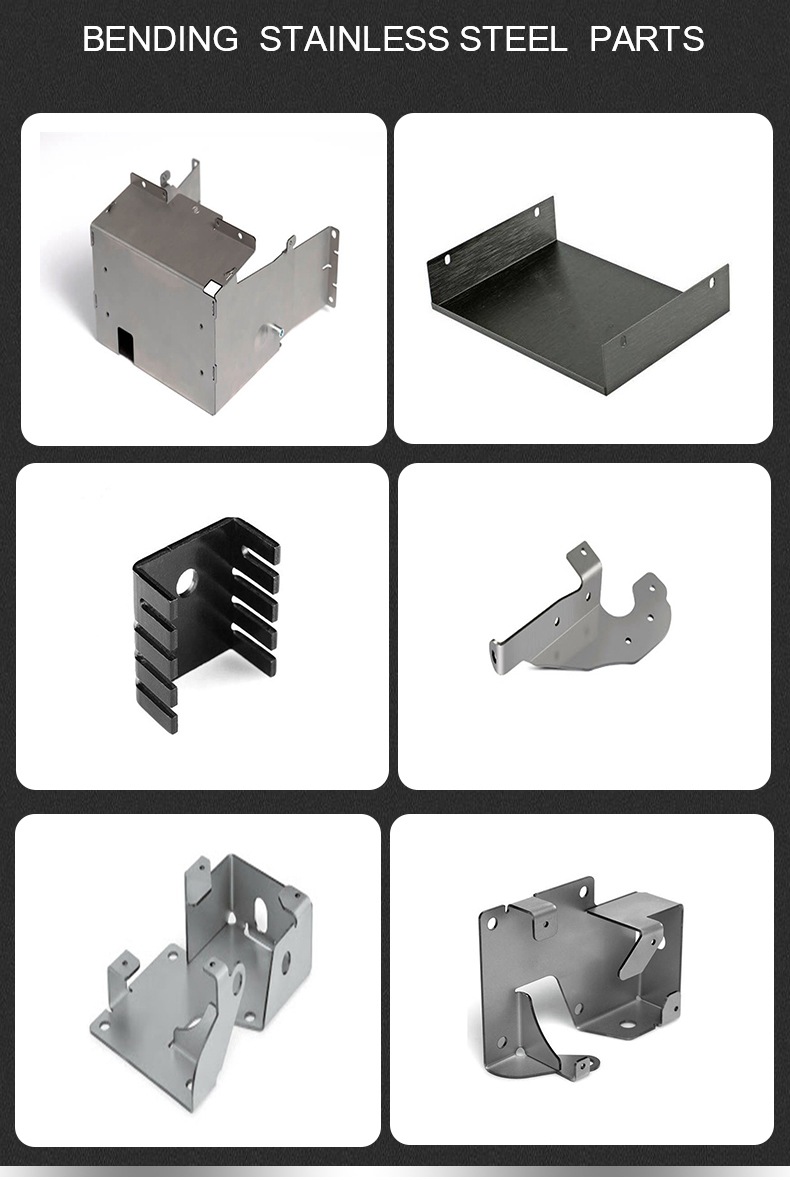

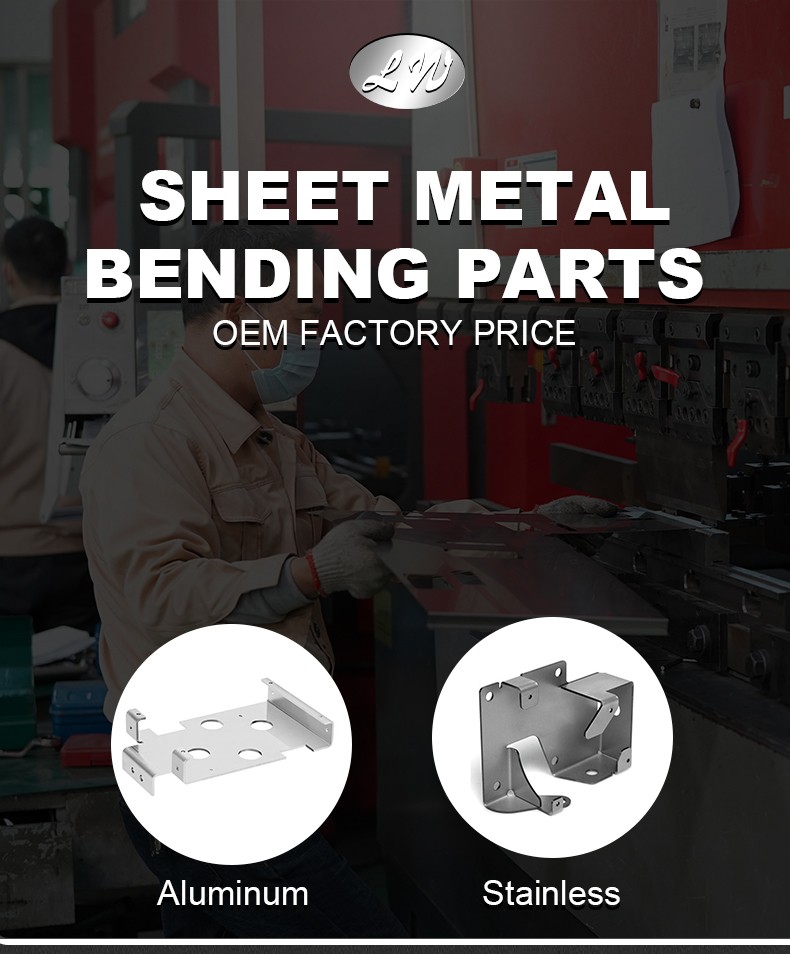

Precision Parts Sheet Metal Processing Bending Parts Processing

Bending thickness up to 8mm

Years of industry experience, focusing on non-standard precision structural parts sheet metal processing, large structural parts prototype processing

With no-mode production, sheet metal processing, rapid plate-making, small batch processing

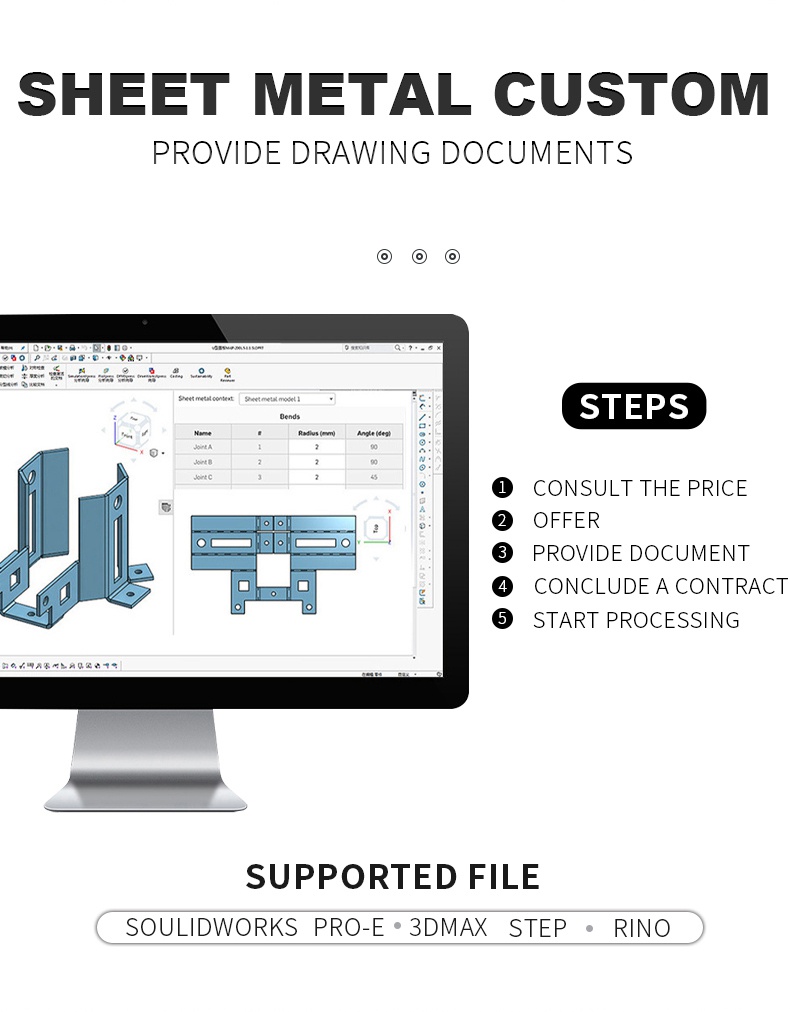

Precision parts sheet metal processing refers to the process of precision machining parts using sheet metal processing technology. We support Sheet Metal Bending Parts Dies processing. Sheet metal processing is a technology for manufacturing parts by cutting, bending, punching, pressing and other processing processes on sheet metal. In the sheet metal processing of precision parts, it is necessary to use high-precision equipment and tools, such as CNC bending machines, laser cutting machines, CNC punching machines, etc., to ensure the accuracy and quality of processing. At the same time, it is also necessary to select the appropriate material and processing technology according to the shape, size and requirements of the part.

Sheet metal processing of precision parts is widely used in machinery manufacturing, electronic equipment, medical equipment and other fields. These fields have very high requirements on the precision and quality of parts, so sheet metal processing of precision parts has important application value. We also have Sheet Metal Bending Parts For Sale, if you have needs, you can contact us.

If you need customization, or Sheet Metal Bending Parts Diy, you can contact us, we specialize in the production of metal processing parts, have a professional factory, professional processing, professional production, more styles, more models, more private customization, more Details can go to our website to view.

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T, etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1, TA2/GR2, TA4/GR5, TC4, TC18, etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM, Acrylic, PC, etc. | |

| Finish | Sandblasting, Anodized color, Blackening, Zinc/Nickl Plating, Polish, |

| Powder coating, Passivation PVD, Titanium Plating, Electro galvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing, Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling Machine, Laser Cutting Machine, etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

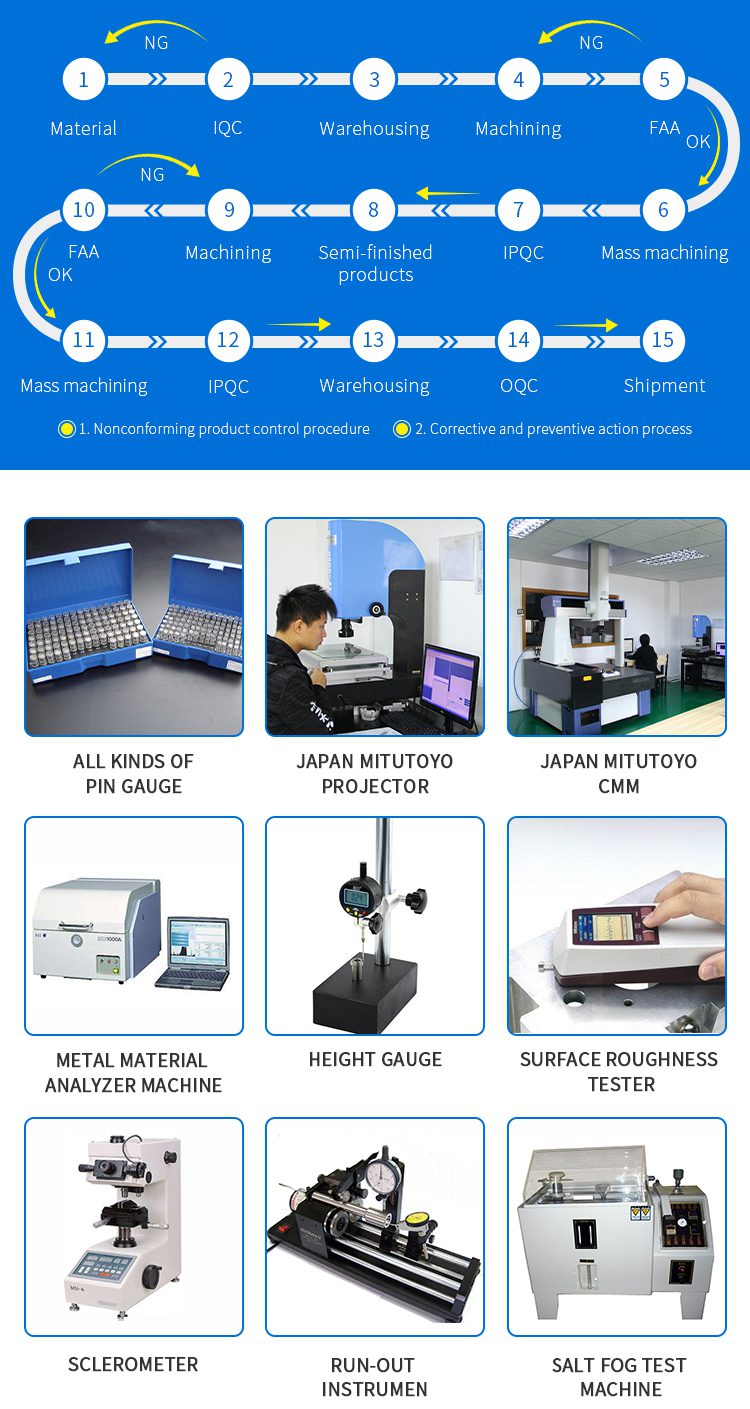

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier, CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |