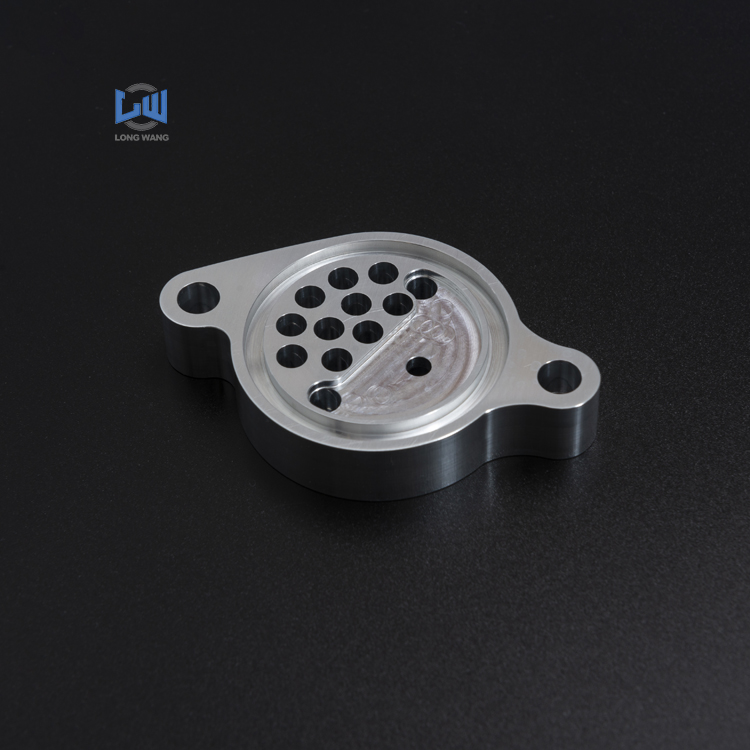

CNC Machining Custom Aluminum Parts

Category: Aluminum Precision Automotive Parts

Product Name: CNC Automotive Parts

Processing method: CNC machining of aluminum alloy parts

Material: aluminum alloy

Surface treatment: polishing, deburring, oxidation

Processing cycle: 3-7 seven working days

Test standard: 3D drawings provided by the customer

Data format: STP/IGS/X.T/PRO/DWG

Product features: smooth surface, high gloss, and fine workmanship

Dongguan Longwang Hardware Co., Ltd is a precision machining company specializing in design, processing, and sales. Our main machining process includes non-standard parts cutting, precision hardware parts, stainless steel parts machining, and mechanical parts machining. The products are widely used in various fields such as household appliances, instruments, and meters, communication, aerospace, computers, mechanical equipment, automotive accessories, etc. The raw materials include stainless steel, iron, copper, aluminum, etc.

The company has strong technical strength and currently has advanced machining centers, CNC milling machines, precision automatic lathes, turning and milling composite walking machines, punch machines and other supporting production equipment, with complete corresponding testing and testing facilities. With rich professional experience and technological strength, we continuously innovate and strive for excellence from product design to component manufacturing, providing users with high-performance products. We can also undertake the machining of incoming materials, small and medium-sized batch parts, design, manufacturing, drawings, and customized samples according to customer requirements.

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T, etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1, TA2/GR2, TA4/GR5, TC4, TC18, etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM, Acrylic, PC, etc. | |

| Finish | Sandblasting, Anodized color, Blackening, Zinc/Nickl Plating, Polish, |

| Powder coating, Passivation PVD, Titanium Plating, Electro galvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing, Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center (Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling Machine, Laser Cutting Machine, etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper&nbs p;Vernier, CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |