CNC Aluminum Parts Machining High Precision

High precision 7075 CNC milling machining service

Supply 5000 series 6000 series 7000 series aluminum

Supply from raw material to machining and assembly one-stop service

10 engineers supply the professional suggestion for your new project

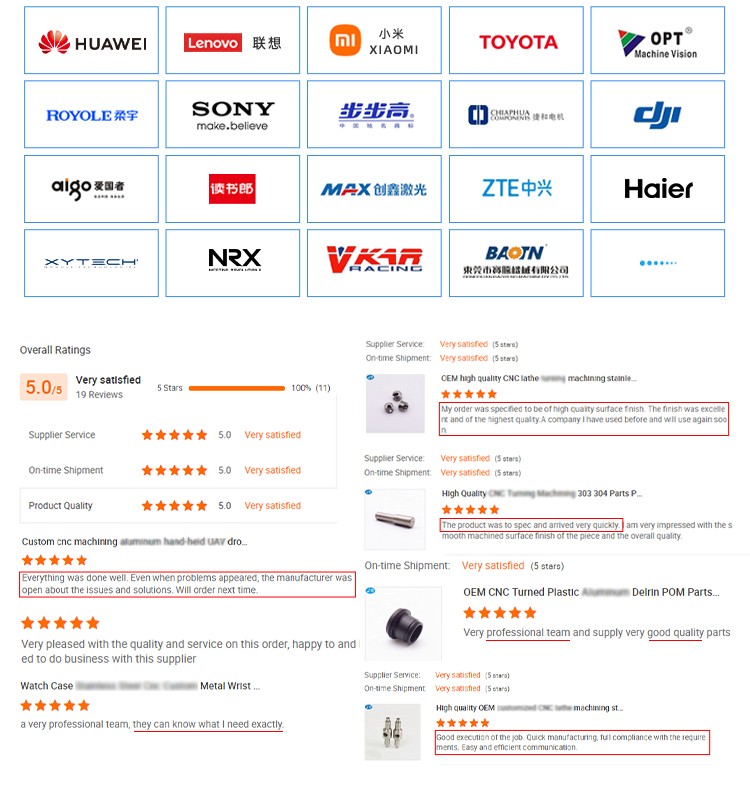

Best price with best quality

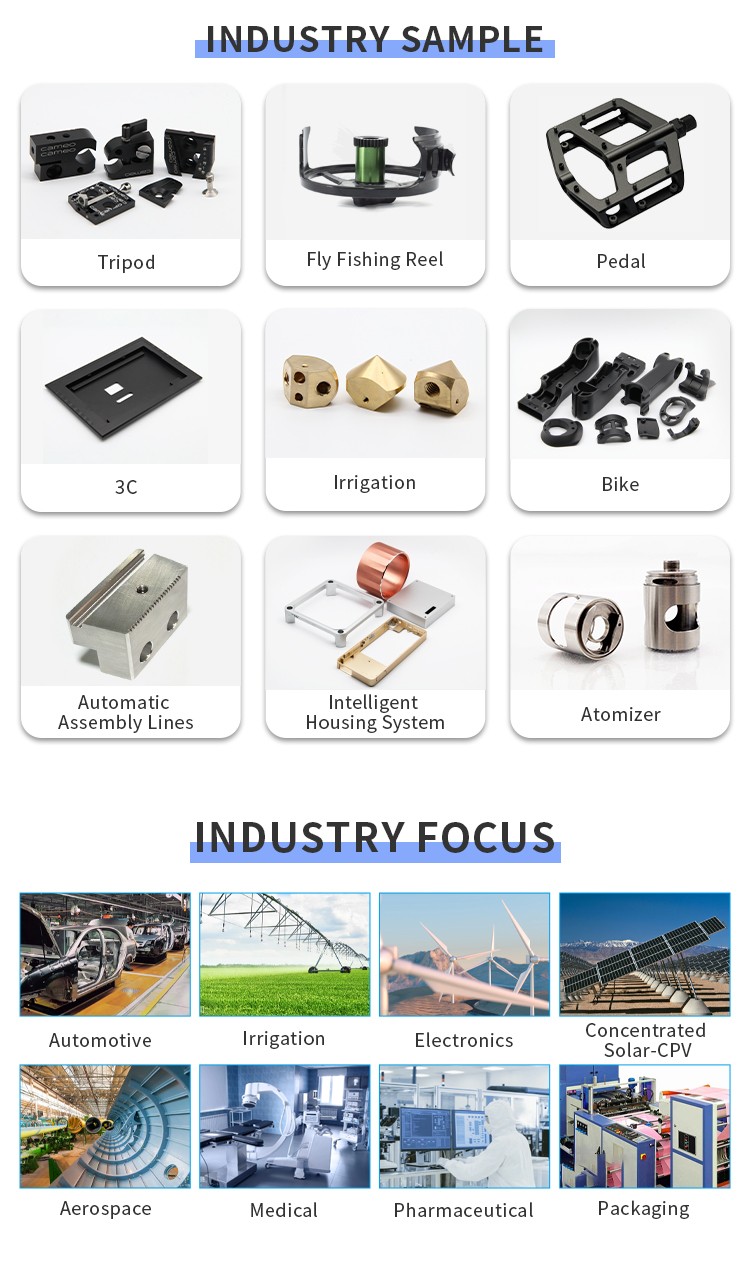

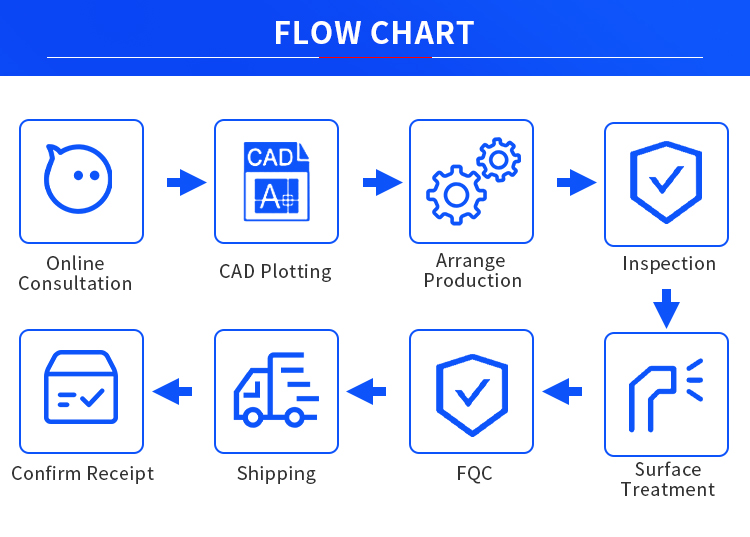

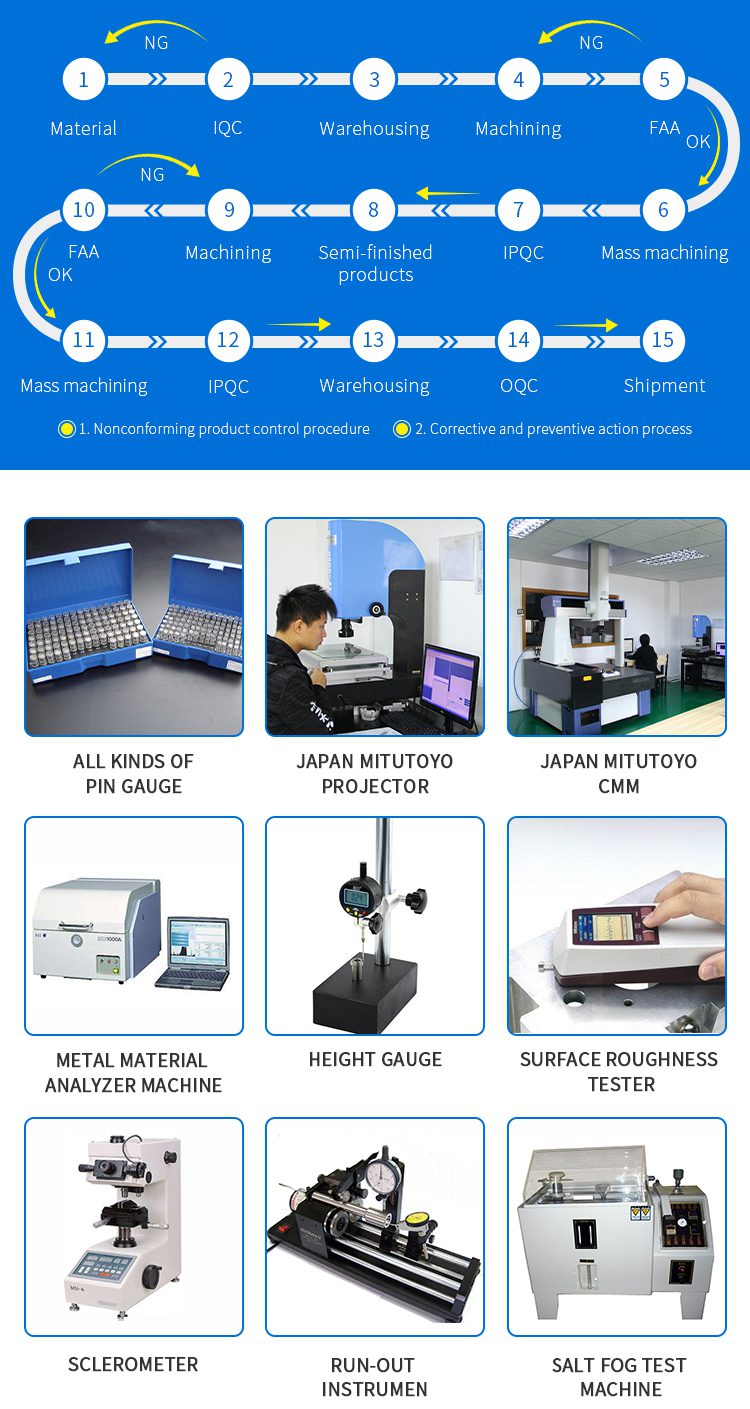

We produce Aluminum Parts Processing Density of different specifications, the material is guaranteed, and products with special quality requirements, we also carry out full inspection. Good inspection equipment and skilled inspectors ensure the quality of our products! It can be customized on demand, manufacturers love direct sales, and the quality is stable. Our professional quality.

Factory direct sales, real materials, Aluminum Parts Processing Design, complete specifications and models, can be processed and customized. The spot is complete, and it can also be customized on demand, and the delivery is rapid, and the large quantity is preferential. We have a large R&D team and a complete system, and it is your wise decision to choose us for excellent quality.

We operate in good faith, all are factory direct sales, original manufacturing, quality assurance, and regular specifications are in stock. If you need to customize different Aluminum Parts Processing In Cars, you can also contact us. Women have sufficient stock, fast delivery, various styles, and support customization. Integrated service support, with mold workshop, processing workshop, spraying workshop.

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T, etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1, TA2/GR2, TA4/GR5, TC4, TC18, etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM, Acrylic, PC, etc. | |

| Finish | Sandblasting, Anodized color, Blackening, Zinc/Nickl Plating, Polish, |

| Powder coating, Passivation PVD, Titanium Plating, Electro galvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing, Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling Machine, Laser Cutting Machine, etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier, CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |