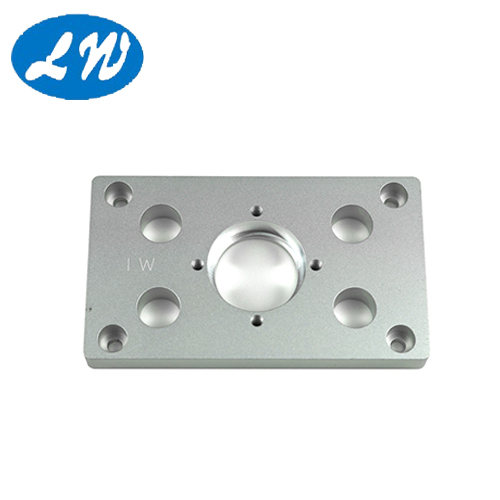

Aluminum Parts Processing High Quality Processing

High precision 7075 CNC milling machining service

Supply 5000 series 6000 series 7000 series aluminum

Supply from raw material to machining and assembly one-stop service

10 engineers supply the professional suggestion for your new project

Best price with best quality

OEM aluminum CNC machining 7075 aluminum machining quantity aluminum alloy milling CNC customized OEM CNC machining parts

Aluminum Machining can use various CNC machining equipment, such as CNC lathes, CNC milling machines, CNC machining centers, etc. These devices can realize high-speed and high-precision CNC Machining, which greatly improves the efficiency and quality of aluminum parts processing. Aluminum CNC machining refers to the process of using CNC machine tools to process aluminum alloy materials. CNC machining has the advantages of high efficiency, high precision, and good repeatability, and is widely used in the field of aluminum parts manufacturing. CNC machining usually includes the following steps:

CAD design: Use computer-aided design software to draw a three-dimensional model of the aluminum part.

CAM programming: Use computer-aided manufacturing software to convert the 3D model of CAD design into a CNC machining program.

Pretreatment: analyze the processing technology to determine the best cutting tool and processing parameters, etc.

Processing: transfer the CNC processing program to the CNC machine tool for automatic processing.

Inspection: inspect the processed aluminum parts to ensure that they meet the design requirements.

CNC machining of aluminum parts can manufacture aluminum parts of various shapes and sizes, including housings, parts, structural parts, etc. It is widely used in aviation, automobile, electronics and other industries. We also have Steel Machining, if you need, you can contact us.

| Business Type | Factory / Manufacturer |

| Service | CNC Machining |

| Turning and Milling | |

| CNC Turning | |

| OEM Parts | |

| Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T, etc |

| 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | |

| 3). Steel: 4140, Q235, Q345B,20#,45# etc. | |

| 4). Titanium: TA1, TA2/GR2, TA4/GR5, TC4, TC18, etc | |

| 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | |

| 6). Copper, bronze, Magnesium alloy, Delrin, POM, Acrylic, PC, etc. | |

| Finish | Sandblasting, Anodized color, Blackening, Zinc/Nickl Plating, Polish, |

| Powder coating, Passivation PVD, Titanium Plating, Electro galvanizing, | |

| electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | |

| Electro Polishing, Chrome Plating, Knurl, Laser etch Logo, etc. | |

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, |

| Cylindrical grinder machine, Drilling Machine, Laser Cutting Machine, etc. | |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

| Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier, CMM |

| Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm |