CNC machined strut spacers are small blocks that are placed on top of the strut assembly in order to lift the vehicle's suspension. These spacers are typically made out of aluminum or steel.CNC machined 6061 T6 (T6 refers to the temper or hardness of the material) hub parts are components that are used in the assembly of a vehicle's wheel hub.

Contact Now

Fine design, excellence, production fine to every detail. Our technical innovation, complex and difficult surface and functional structural prototype models can be quickly prototyped and maintain precise originality. We have Sheet Metal Cabinet for sale, using real materials and refusing to cut corners. Good and durable.Factory direct sales, quality assurance, cost-effective. According to the needs of customers, customize exclusive processing solutions. Mature processing technology, strict quality inspection of ex-factory products. We are a physical factory with professional equipment.

Contact Now

With the popularity of four-wheel drive vehicles, the demand for off-road performance is also increasing. For off-road enthusiasts, modification is also an inevitable topic. Among numerous modifications, Strut Spacers is a highly regarded one.

Contact Now

A customized machined aluminum base is a type of component that is made using CNC machining processes. It is typically used as a foundation or support for other parts or products and is often found in various industrial settings such as manufacturing, aerospace, and robotics.The aluminum material used in the machining process is typically a high-strength alloy, such as 6061-T6 aluminum.

Contact Now

Aluminum alloy is an essential industrial material and a commonly used CNC machining material. Due to its interesting thermal properties and excellent machinability, it is the preferred material for most manufacturing departments in many industries.

Contact Now

The double caliper rear bracket after CNC machining is a high-precision mechanical component widely used in the fields of automobile manufacturing and modification. The rear bracket can simultaneously install two brake calipers, making the car's braking system more stable and reliable, improving driving safety.In addition to the automotive manufacturing and modification fields, the rear bracket can also be applied to other mechanical equipment and engineering fields.

Contact Now

With the continuous advancement and innovation of science and technology, the aircraft industry has developed rapidly in recent years. Among them, UAV technology, as one of the important fields, has become the focus of people's research and attention. In the manufacturing process of drones, aluminum alloy CNC machining parts are more and more widely used.In the manufacturing process of drones, aluminum alloy CNC processing parts are widely used in aircraft shells, chassis, brackets, transmission systems, etc.

Contact Now

We produce burr-free edges and fast delivery times. The source of powerful manufacturers, no middlemen to make the difference, the price is reasonable and affordable. We are interested in consulting and making reasonable quotations. Meticulous selection of materials, customized materials, Sheet Metal Fabrication. Visible quality quality, professional craftsmanship.We have Stamping Part on sale, which supports customized processing of different parts. Have a professional business team, technical team, quality inspection team and customer service team. Good quality can stand the test.

Contact Now

Aluminum Machining processing of aluminum alloy CNC parts is an automatic processing method of aluminum alloy parts using CNC machine tools. As a commonly used material with light weight, high strength and good corrosion resistance, aluminum alloy has been widely used in aerospace, automobile, electronics, machinery and other fields.We can select the appropriate aluminum alloy material according to the RC Car Parts part drawing, and then cut the material into a blank that meets the processing size of the part.

Contact Now

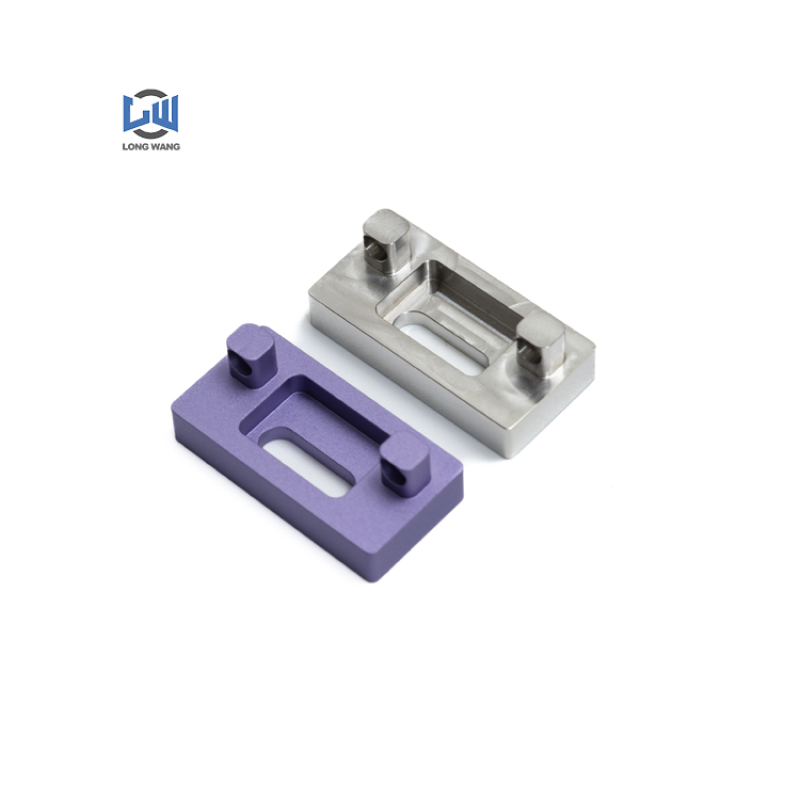

Mechanical keyboard CNC machining is one of Longwang's main businesses. With years of industry experience, Longwang can meet the processing needs of aluminum alloy precision parts for a large number of customers. The mature CNC machining process empowers the company's products.

Contact Now

High-quality Aluminum Steel Machining, focusing on R&D, manufacturing, processing and sales of aluminum alloy products. The materials we produce are all real materials with guaranteed quality. Turning refers to a part of lathe processing and mechanical processing. Lathe processing mainly uses turning tools to turn rotating workpieces.

Contact Now

Aluminum alloy processing is a very important part of modern manufacturing, and customized processing is an inevitable choice to meet specific needs. CNC aluminum alloy processing, as a high-precision, high-efficiency, and highly flexible processing method, is increasingly favored by people.If you have a need for aluminum alloy parts, customized processing is definitely the best choice!

Contact Now

There are 7075 Aluminum Machining for sale, we are a manufacturer supplying and operating with integrity. Various specifications, support customization. Our years of industry production experience is trustworthy. We pay attention to details, select materials, and considerate service. Our factory supplies, the quality is trustworthy. Our company has advanced equipment and faces customers with high-quality services.If you need Machining Aluminum Alloys, we support customization and wholesale.

Contact Now

We have cnc machining aluminum for sale, carefully designed, reasonable collocation of various processes, working attitude of excellence, mature and stable processing technology, so as to fully guarantee the high quality and high performance of the product. We have complete certificates, please rest assured to buy. Provide customers with excellent products. We have a complete quality inspection system.A variety of aluminum machining parts of different specifications are also available for sale.

Contact Now

We provide high-quality Aluminum Cnc Machining Service, powerful manufacturers, and professional recommendations. Compressive and wear-resistant technology, cold and heat resistant. Fine workmanship, corrosion resistance. Various specifications, fine craftsmanship, pressure and wear resistance, compact structure, and long-lasting durability.

Contact Now

Aluminum machining is an important manufacturing process, and 4-axis aluminum milling is a common way of doing it. Aluminum alloy is a lightweight, high-strength metal material widely used in aviation, automobiles, electronics, construction and other fields. The processing of aluminum alloy parts is a very important part. When machining aluminum alloy parts, using a 4-axis milling machine can achieve efficient and precise machining.Compared with traditional 3-axis milling, this method can more accurately process complex shapes and structures, and can also improve production efficiency.

Contact Now

Common Aluminum Machining has many years of processing experience and has been engaged in metal processing for many years. The price is reasonable, the delivery is fast, and the cost performance is high. Welcome to consult. We have strong technical strength, rigorous process, non-standard customization, excellent price, and perfect service system. Welcome to consult.In addition to processing and producing parts, we also support Cutting Discs For Aluminum, which supports cutting of different parts.

Contact Now

In the processing of precision parts, the main dimensional requirements are, for example, the diameter of a cylinder, which is a strict requirement; The positive and negative difference is only the qualified part within the specified range, otherwise it is the irrelevant part; There are also strict requirements for dimensions; Negative parallax and positive parallax also need to be embedded in cylinders (such as very simple basic components), and so on. When the diameter outside the tolerance range is large enough, it cannot be inserted.

Contact Now

We have Aluminum Cnc Online for sale, machining different parts, high quality machining process. With rich industry experience, we win the market with quality and reputation with service. Fast production cycle, technological innovation, advanced technology, source of strength factory, quality assurance, advanced numerical control equipment, perfect after-sales service.We have different Types Of Aluminum For Machining production, as long as you need, we can customize. We also support drawing production and sample customization.

Contact Now

Professional Aluminum Machining is all on our website, we support customization more, we have a large stock, and support wholesale. If you customize a large quantity, we also have a price discount. It is better to act than to be excited, act quickly, we will reply you as soon as we see your message.We have an excellent Aluminum Profile Machining Center, specializing in the production of parts, with many years of experience, fast processing speed, guaranteed material, high precision, and high-precision testing instruments to ensure that each product meets the standard.

Contact Now

Product IntroductionAn Aluminum Sleeve Housing is a robust and versatile component designed for protecting and encasing various mechanical or electronic elements. Made from high-grade aluminum, this housing provides a durable and lightweight solution for shielding sensitive components from environmental factors such as dust, moisture, and mechanical damage.

Contact Now

We produce Aluminum Parts Processing Density of different specifications, the material is guaranteed, and products with special quality requirements, we also carry out full inspection. Good inspection equipment and skilled inspectors ensure the quality of our products! It can be customized on demand, manufacturers love direct sales, and the quality is stable. Our professional quality.Factory direct sales, real materials, Aluminum Parts Processing Design, complete specifications and models, can be processed and customized.

Contact Now

A high-quality CNC Machining processing part usually requires multiple inspections to achieve excellent quality. We insist on fast sales and reasonable pricing, and require sales staff to communicate with customers heart-to-heart and face-to-face. At the same time, the company adheres to standardized operations, does not pursue high profit margins, and sticks to the bottom line of value.Support customized Steel Maching, our production has the advantages of high precision, standard size, accurate delivery, etc., and is well received by major customers.

Contact Now

Screws are hardware parts used to connect and fix materials, usually made of metal materials such as steel, stainless steel, copper, and aluminum. They are available in various heads, threads and lengths to meet the needs of different applications. We have different CNC Drone Parts production which are manufactured using CNC machine tools for cutting, engraving, drilling and milling processes to obtain precise shapes and dimensions.CNC Drone Parts are mechanical parts used to manufacture and assemble drones, usually made of materials such as metal, plastic or carbon fiber.

Contact Now