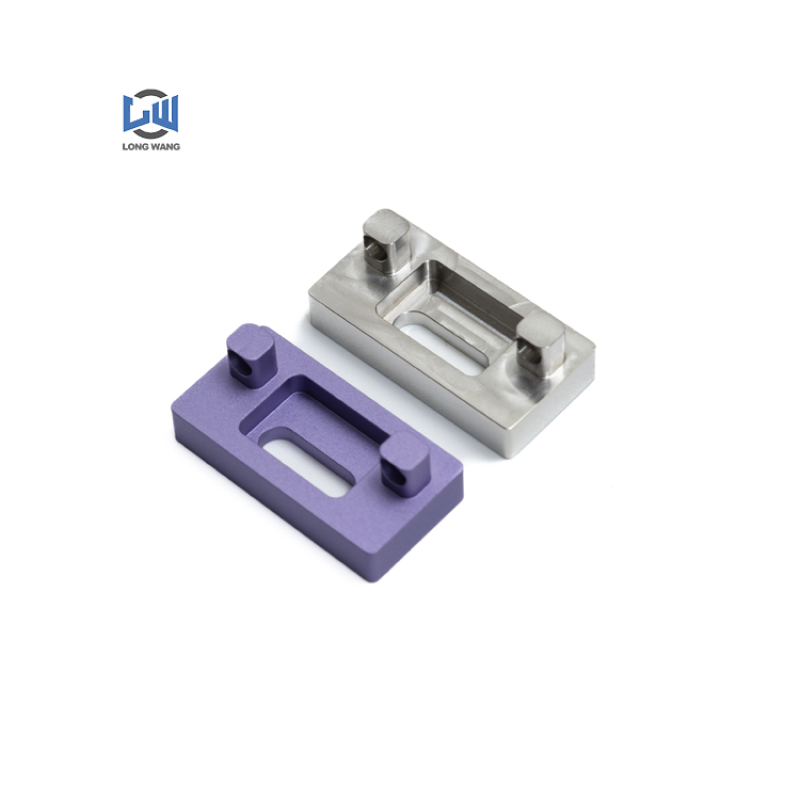

We have Mini computer enclosure for sale, high strength, light weight, high assembly precision. On the premise of satisfying the function, we constantly upgrade the overall lightweight, degree and assembly time. Because we are the source manufacturer, we have excellent material selection and fine workmanship. Support processing customization, quality control.We have different Sheet Matel Enclosures with complete wiring types and reasonable prices. Our Electronic Equipment Co., Ltd.

Contact Now

Stamping processing, one-stop precision parts processing customization, quick sample production, complete process. We can also provide one-stop processing services such as sheet metal bending and assembly. Our product production has a professional quality inspection team to provide quality commitments. Has many years of technical force and management experience and advanced production equipment.We have Sheet Metal Fabrication, which is a key technology that sheet metal technicians need to master, and an important process for forming sheet metal products.

Contact Now

We have cnc machining aluminum for sale, carefully designed, reasonable collocation of various processes, working attitude of excellence, mature and stable processing technology, so as to fully guarantee the high quality and high performance of the product. We have complete certificates, please rest assured to buy. Provide customers with excellent products. We have a complete quality inspection system.A variety of aluminum machining parts of different specifications are also available for sale.

Contact Now

We produce burr-free edges and fast delivery times. The source of powerful manufacturers, no middlemen to make the difference, the price is reasonable and affordable. We are interested in consulting and making reasonable quotations. Meticulous selection of materials, customized materials, Sheet Metal Fabrication. Visible quality quality, professional craftsmanship.We have Stamping Part on sale, which supports customized processing of different parts. Have a professional business team, technical team, quality inspection team and customer service team. Good quality can stand the test.

Contact Now

We are a powerful processing factory of Sheet Metal Box, focusing on the processing of parts of different materials and CNC processing. We have many years of experience in processing and production, and have won the recognition of new and old customers. Customers are welcome to come to consult, we undertake batch customized processing products.

Contact Now

We have Remote Control Car In Parts on sale. We use professional testing equipment to conduct strict testing on the products to ensure the standard of the products, so that you can buy with confidence. Support customization, customized according to drawings and samples, we will provide you with reference solutions. Our products are all taken in kind and can be customized.There are expensive ones and some cheap ones, but we have Inexpensive RCCar Parts on sale, and all kinds of materials can be customized according to your needs.

Contact Now

We have Mini computer enclosure for sale, we are a manufacturer, support customization, professional processing, and trustworthy quality. We are also a production and processing company with a complete and scientific quality management system. Our integrity, strength and product quality are recognized by the industry.We support one-stop service production strength manufacturers tailored for you. There is Sheet Metal Fabrication for sale. Our products can be used in most industries, such as the robotics industry, the communication industry, and the home appliance industry.

Contact Now

There are 7075 Aluminum Machining for sale, we are a manufacturer supplying and operating with integrity. Various specifications, support customization. Our years of industry production experience is trustworthy. We pay attention to details, select materials, and considerate service. Our factory supplies, the quality is trustworthy. Our company has advanced equipment and faces customers with high-quality services.If you need Machining Aluminum Alloys, we support customization and wholesale.

Contact Now

High-quality Aluminum Steel Machining, focusing on R&D, manufacturing, processing and sales of aluminum alloy products. The materials we produce are all real materials with guaranteed quality. Turning refers to a part of lathe processing and mechanical processing. Lathe processing mainly uses turning tools to turn rotating workpieces.

Contact Now

We have Sheet Metal Enclosure for sale, specifications and sizes, can be customized according to customer requirements, quality is guaranteed, and fast delivery. Specifications, materials, colors and other processes can be customized on demand, with beautiful appearance, reliable performance, guaranteed quality, excellent quality, and more support for fast delivery, so that you can receive the goods quickly without worrying about out of stock.Even for Sheet Metal Cabinet, we can also process and customize. Size: Any length can be changed according to your request.

Contact Now

The materials commonly processed by cnc turning machining are free-cutting steel and copper. The free-cutting steel is made of materials with high sulfur content S and phosphorus content P. Sulfur and manganese exist in the form of manganese sulfide in the steel.The commonly used material for modern lathe machining is aluminum alloy material, which has a significantly reduced density compared to iron and steel materials. Moreover, lathe machining is less difficult, has strong plasticity, and greatly reduces product weight. This also greatly shortens the time for lathe machining parts.

Contact Now

We have advanced CNC equipment, a complete after-sales system, and a professional design team to produce RC Car parts. We have been focusing on it for many years, only to do a good job in every product. Precise CNC machining parts, precision machining. Any cutting, customized processing, factory direct sales.Intimate service, fast response, we have a professional team to escort you, the price is affordable, the toy stainless steel part produced, the quality is guaranteed, and integrity is the magic weapon for us to win customers. Customer satisfaction is our pursuit.

Contact Now

We have Aluminum Cnc Online for sale, machining different parts, high quality machining process. With rich industry experience, we win the market with quality and reputation with service. Fast production cycle, technological innovation, advanced technology, source of strength factory, quality assurance, advanced numerical control equipment, perfect after-sales service.We have different Types Of Aluminum For Machining production, as long as you need, we can customize. We also support drawing production and sample customization.

Contact Now

We have a professional team, rich industry experience, advanced technical equipment, and processing according to drawings and samples. We specialize in hardware processing customization. Quality is guaranteed. Fine workmanship, one-stop customization. A variety of treatment processes meet your needs. The product material is guaranteed and the precision is high. Short production cycle and on-time delivery.CNC Turning automatically processes the processed parts according to the pre-programmed processing program.

Contact Now

We have CNC Aluminum Keyboard for sale, many authoritative certifications, safety and quality let you rest assured, you can get the certificates, and you can check them online. Most of our products are processed products, please consult us for details. We carefully select the material, the surface is smooth, the hardness is high and the toughness is high, and the service life is long.The CNC Aluminum Keyboard Case we produce is stable in structure, easy to install and use, saves time and effort, and has many applications.

Contact Now

We focus on creating high-precision quality, and customer satisfaction is everything to us. Hardware parts, lathe processing, non-standard customization. Fine processing, exquisite workmanship, fast delivery, a variety of Anodized Aluminum Machining, fast quotation, high-precision quality, and reasonable price. Support map customization to meet your various needs.High-quality products, considerate service. Shorten the factory, we are factory direct sales, there is no middleman to make the price difference.

Contact Now

We have professional staff who have been engaged in CNC Machining processing and mold processing for many years with rich experience. We make good products with our heart and serve you intimately. Experienced operation team, excellent craftsmanship, strict material selection, high work efficiency, and convenient delivery. Choosing us is your wise choice. We have Aluminum Machining production, which integrates production and sales, and the one-stop service makes you feel at ease.

Contact Now

Indispensable to our excellent team is a complete scientific management system. With different Sheet Metal Bending Parts for sale, we have many years of experience in processing. We have many years of experience, professional R&D and design, support for customization, and accurate delivery. Professional workflow, rapid prototyping design and machining services company.Made with our advanced Sheet Metal Bending Process. If you need special requirements for customization, our company can provide customized specifications.

Contact Now

We support custom CNC Aluminum Parts. We are customized by the manufacturer, with large quantity and high price, and the quality is guaranteed. Delivery is on time, there are lathe parts processing parts, CNC lathe processing, precision positioning parts. We have been working hard to give back to customers with hard-core quality products and better services, and reject low-priced, inferior, and rough products.People often say CNC Parts Near Me, but often can't find a shop that suits them.

Contact Now

In the processing of precision parts, the main dimensional requirements are, for example, the diameter of a cylinder, which is a strict requirement; The positive and negative difference is only the qualified part within the specified range, otherwise it is the irrelevant part; There are also strict requirements for dimensions; Negative parallax and positive parallax also need to be embedded in cylinders (such as very simple basic components), and so on. When the diameter outside the tolerance range is large enough, it cannot be inserted.

Contact Now

This Sheet Metal Box, with exquisite details and ingenious quality, can use a variety of materials, such as stainless steel. Can cut boards with different thicknesses. After the material is cut, the material properties of the cutting accessories are hardly affected, and the workpiece is not easily deformed. High precision and excellent kerf geometry.We have different CNC machining for sale, professional parts processing, many years of experience, perfect after-sales service, don't worry about after-sales problems that can't be solved.

Contact Now

Mechanical keyboard CNC machining is one of Longwang's main businesses. With years of industry experience, Longwang can meet the processing needs of aluminum alloy precision parts for a large number of customers. The mature CNC machining process empowers the company's products.

Contact Now

Our RC Car Parts use computer-aided design software (such as SolidWorks, AutoCAD, etc.) to design a 3D model of the parts that need to be manufactured. This process needs to take into account the size, shape, material and other factors of the part. Import the designed 3D model into CAM software (such as MasterCAM, CATIA, etc.), set tools, cutting parameters, etc., and generate CNC machining programs.According to your design drawings and CNC codes, we can choose suitable materials, such as metal, plastic or wood, and then cut them to the appropriate size and shape.

Contact Now