Aluminum alloy is an essential industrial material and a commonly used CNC machining material. Due to its interesting thermal properties and excellent machinability, it is the preferred material for most manufacturing departments in many industries.

Contact Now

We have cnc machining aluminum for sale, carefully designed, reasonable collocation of various processes, working attitude of excellence, mature and stable processing technology, so as to fully guarantee the high quality and high performance of the product. We have complete certificates, please rest assured to buy. Provide customers with excellent products. We have a complete quality inspection system.A variety of aluminum machining parts of different specifications are also available for sale.

Contact Now

Professional Aluminum Machining is all on our website, we support customization more, we have a large stock, and support wholesale. If you customize a large quantity, we also have a price discount. It is better to act than to be excited, act quickly, we will reply you as soon as we see your message.We have an excellent Aluminum Profile Machining Center, specializing in the production of parts, with many years of experience, fast processing speed, guaranteed material, high precision, and high-precision testing instruments to ensure that each product meets the standard.

Contact Now

There are 7075 Aluminum Machining for sale, we are a manufacturer supplying and operating with integrity. Various specifications, support customization. Our years of industry production experience is trustworthy. We pay attention to details, select materials, and considerate service. Our factory supplies, the quality is trustworthy. Our company has advanced equipment and faces customers with high-quality services.If you need Machining Aluminum Alloys, we support customization and wholesale.

Contact Now

Our RC Car Parts use computer-aided design software (such as SolidWorks, AutoCAD, etc.) to design a 3D model of the parts that need to be manufactured. This process needs to take into account the size, shape, material and other factors of the part. Import the designed 3D model into CAM software (such as MasterCAM, CATIA, etc.), set tools, cutting parameters, etc., and generate CNC machining programs.According to your design drawings and CNC codes, we can choose suitable materials, such as metal, plastic or wood, and then cut them to the appropriate size and shape.

Contact Now

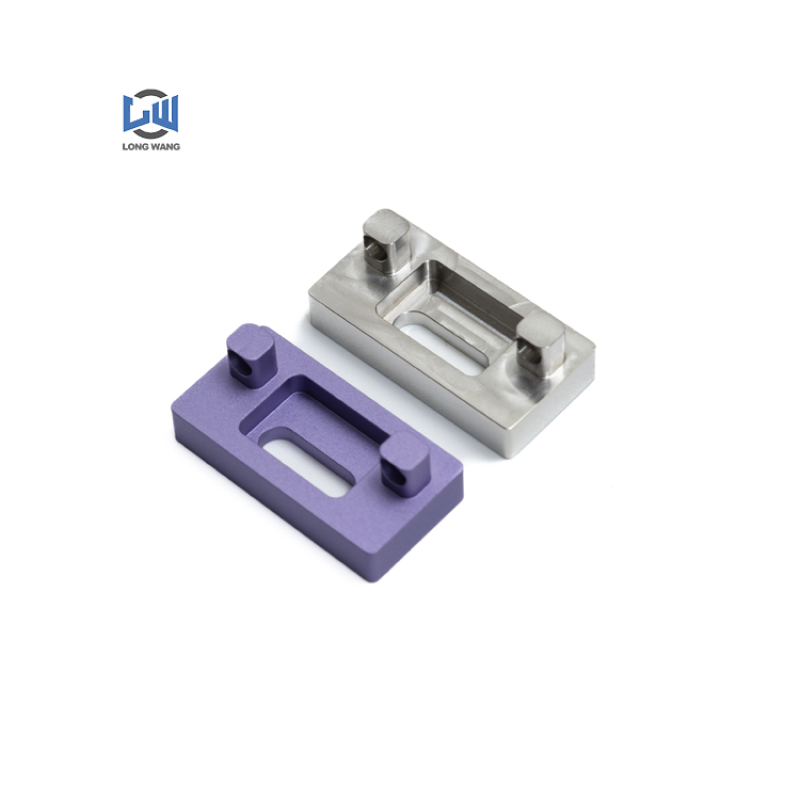

Mechanical keyboard CNC machining is one of Longwang's main businesses. With years of industry experience, Longwang can meet the processing needs of aluminum alloy precision parts for a large number of customers. The mature CNC machining process empowers the company's products.

Contact Now

We produce burr-free edges and fast delivery times. The source of powerful manufacturers, no middlemen to make the difference, the price is reasonable and affordable. We are interested in consulting and making reasonable quotations. Meticulous selection of materials, customized materials, Sheet Metal Fabrication. Visible quality quality, professional craftsmanship.We have Stamping Part on sale, which supports customized processing of different parts. Have a professional business team, technical team, quality inspection team and customer service team. Good quality can stand the test.

Contact Now

Aluminum Machining processing of aluminum alloy CNC parts is an automatic processing method of aluminum alloy parts using CNC machine tools. As a commonly used material with light weight, high strength and good corrosion resistance, aluminum alloy has been widely used in aerospace, automobile, electronics, machinery and other fields.We can select the appropriate aluminum alloy material according to the RC Car Parts part drawing, and then cut the material into a blank that meets the processing size of the part.

Contact Now

We provide high-quality Aluminum Cnc Machining Service, powerful manufacturers, and professional recommendations. Compressive and wear-resistant technology, cold and heat resistant. Fine workmanship, corrosion resistance. Various specifications, fine craftsmanship, pressure and wear resistance, compact structure, and long-lasting durability.

Contact Now

We have advanced CNC equipment, a complete after-sales system, and a professional design team to produce RC Car parts. We have been focusing on it for many years, only to do a good job in every product. Precise CNC machining parts, precision machining. Any cutting, customized processing, factory direct sales.Intimate service, fast response, we have a professional team to escort you, the price is affordable, the toy stainless steel part produced, the quality is guaranteed, and integrity is the magic weapon for us to win customers. Customer satisfaction is our pursuit.

Contact Now

CNC machined strut spacers are small blocks that are placed on top of the strut assembly in order to lift the vehicle's suspension. These spacers are typically made out of aluminum or steel.CNC machined 6061 T6 (T6 refers to the temper or hardness of the material) hub parts are components that are used in the assembly of a vehicle's wheel hub.

Contact Now

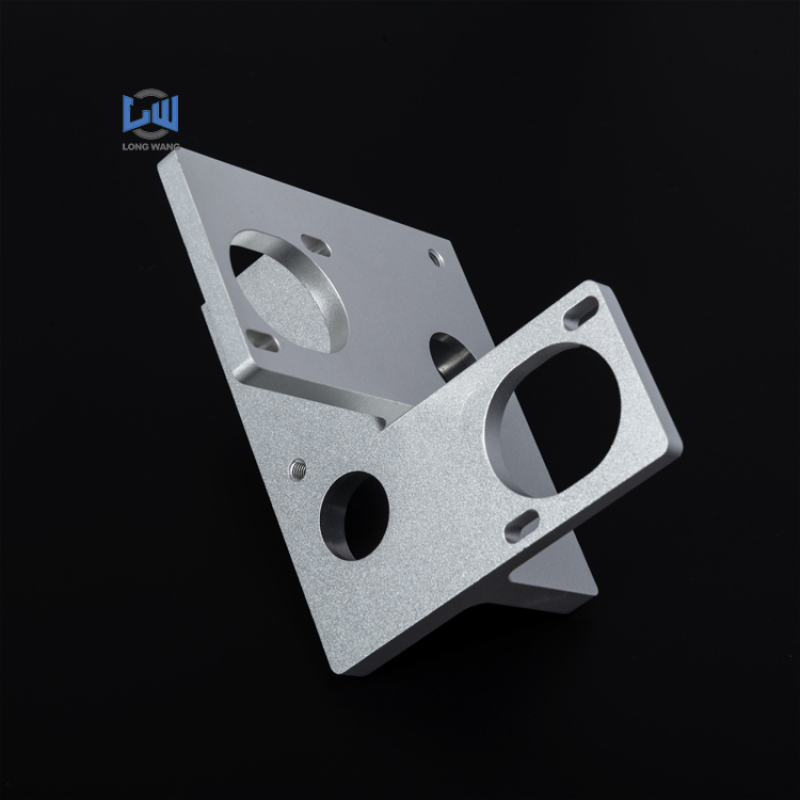

With the continuous advancement and innovation of science and technology, the aircraft industry has developed rapidly in recent years. Among them, UAV technology, as one of the important fields, has become the focus of people's research and attention. In the manufacturing process of drones, aluminum alloy CNC machining parts are more and more widely used.In the manufacturing process of drones, aluminum alloy CNC processing parts are widely used in aircraft shells, chassis, brackets, transmission systems, etc.

Contact Now

We have advanced machinery and equipment, professional technicians, short construction period, every step of the details are in place, and we will create high-quality products wholeheartedly. Mature processing technology can effectively guarantee the pass rate of products and the stability of delivery. Advanced equipment and skilled technology can effectively guarantee the speed of product delivery.We have CNC machining for parts machining of different materials, custom and wholesale. Support steel machining, aluminum machining.

Contact Now

We support a variety of optional specifications, and the processing of drawings can be reasonably customized according to the requirements of customers. We support customized processing of incoming materials and samples, and customized keyboard cnc machining aluminum. We are a word-of-mouth manufacturer, you can choose with confidence and provide customers with high-quality prices.We specialize in custom machining of CNC lathe machining parts, such as custom aluminum keyboard. Professional hepatitis A function long.

Contact Now

In the processing of precision parts, the main dimensional requirements are, for example, the diameter of a cylinder, which is a strict requirement; The positive and negative difference is only the qualified part within the specified range, otherwise it is the irrelevant part; There are also strict requirements for dimensions; Negative parallax and positive parallax also need to be embedded in cylinders (such as very simple basic components), and so on. When the diameter outside the tolerance range is large enough, it cannot be inserted.

Contact Now

We have Aluminum Cnc Online for sale, machining different parts, high quality machining process. With rich industry experience, we win the market with quality and reputation with service. Fast production cycle, technological innovation, advanced technology, source of strength factory, quality assurance, advanced numerical control equipment, perfect after-sales service.We have different Types Of Aluminum For Machining production, as long as you need, we can customize. We also support drawing production and sample customization.

Contact Now

We focus on creating high-precision quality, and customer satisfaction is everything to us. Hardware parts, lathe processing, non-standard customization. Fine processing, exquisite workmanship, fast delivery, a variety of Anodized Aluminum Machining, fast quotation, high-precision quality, and reasonable price. Support map customization to meet your various needs.High-quality products, considerate service. Shorten the factory, we are factory direct sales, there is no middleman to make the price difference.

Contact Now

Aluminum machining is an important manufacturing process, and 4-axis aluminum milling is a common way of doing it. Aluminum alloy is a lightweight, high-strength metal material widely used in aviation, automobiles, electronics, construction and other fields. The processing of aluminum alloy parts is a very important part. When machining aluminum alloy parts, using a 4-axis milling machine can achieve efficient and precise machining.Compared with traditional 3-axis milling, this method can more accurately process complex shapes and structures, and can also improve production efficiency.

Contact Now

We have advanced CNC machining equipment for CNC product parts processing, which efficiently completes various small part customization requirements. The process flow strictly follows the ISO9001 standard, ensuring that the quality of each product meets high standards and fast delivery.Precision CNC machining of complex geometric shapes and providing support for your mechanical engineers in design, validation, and engineering testing. We provide customized processing parts for multiple industries: home appliances, automobiles, electronics, machinery, medical equipment, and robots.

Contact Now

Aluminum alloy processing is a very important part of modern manufacturing, and customized processing is an inevitable choice to meet specific needs. CNC aluminum alloy processing, as a high-precision, high-efficiency, and highly flexible processing method, is increasingly favored by people.If you have a need for aluminum alloy parts, customized processing is definitely the best choice!

Contact Now

High-quality Aluminum Steel Machining, focusing on R&D, manufacturing, processing and sales of aluminum alloy products. The materials we produce are all real materials with guaranteed quality. Turning refers to a part of lathe processing and mechanical processing. Lathe processing mainly uses turning tools to turn rotating workpieces.

Contact Now

In CNC parts precision machining, the design of the part is created using computer-aided design (CAD) software. This design is then translated into a set of instructions for the CNC machine using computer-aided manufacturing (CAM) software. The instructions are sent to the machine's controller, which controls the movement of the cutting tool and the positioning of the workpiece in order to create the desired shape.CNC parts precision machining can be used to produce a wide variety of parts, from small and simple components to large and complex assemblies.

Contact Now

Automotive CNC Machining is an essential component in manufacturing and industrial environments. These parts are designed to work with CNC machines to automate various tasks and increase productivity. Some common CNC automation components include spindles, tool holders, CNC controllers, linear guides, and servo motors.Our RC Car Parts can be sold wholesale individually or as part of a complete CNC system. They are available from various manufacturers and suppliers and can be customized to meet specific machine and application requirements.If you need CNC Keyboard, you can also contact us.

Contact Now

We produce Aluminum Parts Processing Density of different specifications, the material is guaranteed, and products with special quality requirements, we also carry out full inspection. Good inspection equipment and skilled inspectors ensure the quality of our products! It can be customized on demand, manufacturers love direct sales, and the quality is stable. Our professional quality.Factory direct sales, real materials, Aluminum Parts Processing Design, complete specifications and models, can be processed and customized.

Contact Now