Custom CNC Milling Machining Parts, we are professional, support personalized customization, can cut to any size, and provide personalized services. Will adhere to the customer-oriented, quality-oriented strategy. Welcome friends from all walks of life to visit, guide and negotiate business. We focus on customization and establish stable cooperative relationships with many cooperative merchants.We have excellent equipment for processing, and can provide one-stop service from aluminum material production to processing. Applicable to a wide range of scenarios.

Contact Now

In the processing of precision parts, the main dimensional requirements are, for example, the diameter of a cylinder, which is a strict requirement; The positive and negative difference is only the qualified part within the specified range, otherwise it is the irrelevant part; There are also strict requirements for dimensions; Negative parallax and positive parallax also need to be embedded in cylinders (such as very simple basic components), and so on. When the diameter outside the tolerance range is large enough, it cannot be inserted.

Contact Now

With the continuous advancement and innovation of science and technology, the aircraft industry has developed rapidly in recent years. Among them, UAV technology, as one of the important fields, has become the focus of people's research and attention. In the manufacturing process of drones, aluminum alloy CNC machining parts are more and more widely used.In the manufacturing process of drones, aluminum alloy CNC processing parts are widely used in aircraft shells, chassis, brackets, transmission systems, etc.

Contact Now

Aluminum machining is an important manufacturing process, and 4-axis aluminum milling is a common way of doing it. Aluminum alloy is a lightweight, high-strength metal material widely used in aviation, automobiles, electronics, construction and other fields. The processing of aluminum alloy parts is a very important part. When machining aluminum alloy parts, using a 4-axis milling machine can achieve efficient and precise machining.Compared with traditional 3-axis milling, this method can more accurately process complex shapes and structures, and can also improve production efficiency.

Contact Now

Aluminum alloy processing is a very important part of modern manufacturing, and customized processing is an inevitable choice to meet specific needs. CNC aluminum alloy processing, as a high-precision, high-efficiency, and highly flexible processing method, is increasingly favored by people.If you have a need for aluminum alloy parts, customized processing is definitely the best choice!

Contact Now

Aluminum alloy is an essential industrial material and a commonly used CNC machining material. Due to its interesting thermal properties and excellent machinability, it is the preferred material for most manufacturing departments in many industries.

Contact Now

Aluminum alloy milling CNC refers to the process of using a computer numerical control (CNC) machine to mill or cut aluminum alloy material into a desired shape or form. This process involves using a rotating cutting tool to remove material from the workpiece, guided by a computer program that controls the movement of the cutting tool. Aluminum alloy milling CNC is commonly used in manufacturing settings to produce complex and precise parts for a variety of industries, including aerospace, automotive, and engineering.

Contact Now

Aluminum Machining processing of aluminum alloy CNC parts is an automatic processing method of aluminum alloy parts using CNC machine tools. As a commonly used material with light weight, high strength and good corrosion resistance, aluminum alloy has been widely used in aerospace, automobile, electronics, machinery and other fields.We can select the appropriate aluminum alloy material according to the RC Car Parts part drawing, and then cut the material into a blank that meets the processing size of the part.

Contact Now

We have professional automatic lathe processing and CNC lathe processing, including Aluminum Parts Processing Buy, turning and milling composite machining production and collectors. The source manufacturer has stable supply and guaranteed quality. Arbitrary shape, complete specifications, support to map customization. We can process and customize all kinds of precision parts according to the requirements of customers.We have Aluminum Parts Processing Custom.

Contact Now

We have cnc machining aluminum for sale, carefully designed, reasonable collocation of various processes, working attitude of excellence, mature and stable processing technology, so as to fully guarantee the high quality and high performance of the product. We have complete certificates, please rest assured to buy. Provide customers with excellent products. We have a complete quality inspection system.A variety of aluminum machining parts of different specifications are also available for sale.

Contact Now

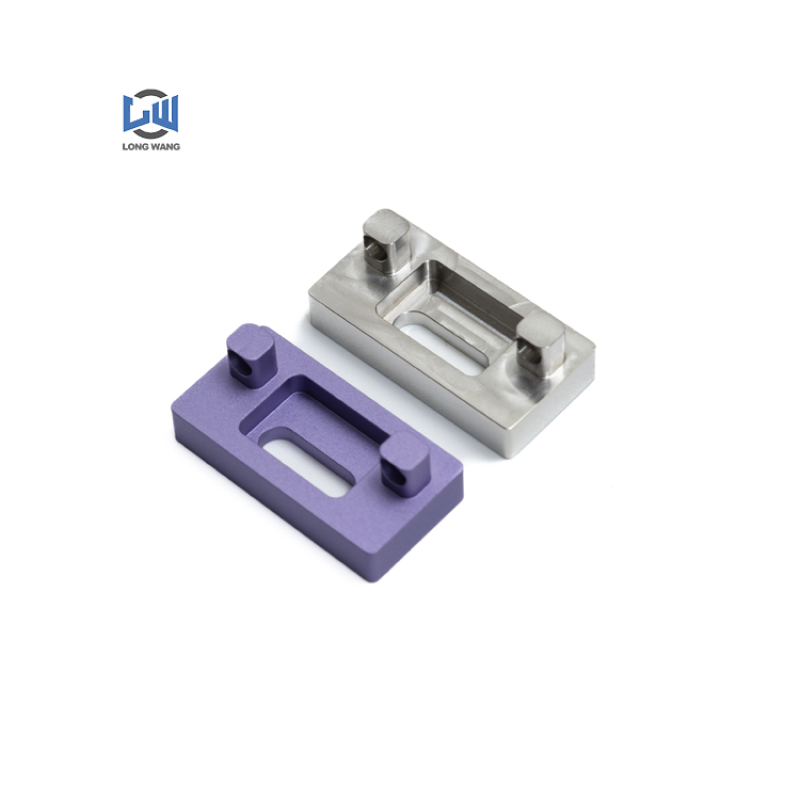

Mechanical keyboard CNC machining is one of Longwang's main businesses. With years of industry experience, Longwang can meet the processing needs of aluminum alloy precision parts for a large number of customers. The mature CNC machining process empowers the company's products.

Contact Now

Our RC Car Parts use computer-aided design software (such as SolidWorks, AutoCAD, etc.) to design a 3D model of the parts that need to be manufactured. This process needs to take into account the size, shape, material and other factors of the part. Import the designed 3D model into CAM software (such as MasterCAM, CATIA, etc.), set tools, cutting parameters, etc., and generate CNC machining programs.According to your design drawings and CNC codes, we can choose suitable materials, such as metal, plastic or wood, and then cut them to the appropriate size and shape.

Contact Now

CNC processing products include mobile phone case processing, cavity-type hardware machining processing, complex curved surface type metal processing, security/communication electronics/tablet computer type metal shells, and internal components; Bicycle parts; Hardware accessories; LED radiators, aviation accessories, medical accessories, etc.By using imported multi-axis milling machines, we can ensure that the tolerance of CNC milling parts is within+/-0.01mm.

Contact Now

Screws are hardware parts used to connect and fix materials, usually made of metal materials such as steel, stainless steel, copper, and aluminum. They are available in various heads, threads and lengths to meet the needs of different applications. We have different CNC Drone Parts production which are manufactured using CNC machine tools for cutting, engraving, drilling and milling processes to obtain precise shapes and dimensions.CNC Drone Parts are mechanical parts used to manufacture and assemble drones, usually made of materials such as metal, plastic or carbon fiber.

Contact Now

Compared to other types of machine tools, five-axis CNC machines will help you save a lot of time. Parts created in most CNC workshops require machining on five sides. 5-axis CNC milling will help complete production quickly and effectively.

Contact Now

We have advanced CNC equipment, a complete after-sales system, and a professional design team to produce RC Car parts. We have been focusing on it for many years, only to do a good job in every product. Precise CNC machining parts, precision machining. Any cutting, customized processing, factory direct sales.Intimate service, fast response, we have a professional team to escort you, the price is affordable, the toy stainless steel part produced, the quality is guaranteed, and integrity is the magic weapon for us to win customers. Customer satisfaction is our pursuit.

Contact Now

CNC machined strut spacers are small blocks that are placed on top of the strut assembly in order to lift the vehicle's suspension. These spacers are typically made out of aluminum or steel.CNC machined 6061 T6 (T6 refers to the temper or hardness of the material) hub parts are components that are used in the assembly of a vehicle's wheel hub.

Contact Now

We provide high-quality Aluminum Cnc Machining Service, powerful manufacturers, and professional recommendations. Compressive and wear-resistant technology, cold and heat resistant. Fine workmanship, corrosion resistance. Various specifications, fine craftsmanship, pressure and wear resistance, compact structure, and long-lasting durability.

Contact Now

We produce burr-free edges and fast delivery times. The source of powerful manufacturers, no middlemen to make the difference, the price is reasonable and affordable. We are interested in consulting and making reasonable quotations. Meticulous selection of materials, customized materials, Sheet Metal Fabrication. Visible quality quality, professional craftsmanship.We have Stamping Part on sale, which supports customized processing of different parts. Have a professional business team, technical team, quality inspection team and customer service team. Good quality can stand the test.

Contact Now

Through the five-axis machining technology, the problem of repeatedly repositioning the workpiece at complex angles has been solved. It not only shortens the time but also improves the machining tolerance many times. It also saves the high cost of making multiple fixtures in traditional ways. 5-axis machining can process complex parts, such as drilling, taper machining, and cavities for complex surfaces, which in most cases cannot be achieved by traditional machining methods. Another advantage of 5-axis CNC machines is that they can cut complex shapes.

Contact Now

There are 7075 Aluminum Machining for sale, we are a manufacturer supplying and operating with integrity. Various specifications, support customization. Our years of industry production experience is trustworthy. We pay attention to details, select materials, and considerate service. Our factory supplies, the quality is trustworthy. Our company has advanced equipment and faces customers with high-quality services.If you need Machining Aluminum Alloys, we support customization and wholesale.

Contact Now

Professional Aluminum Machining is all on our website, we support customization more, we have a large stock, and support wholesale. If you customize a large quantity, we also have a price discount. It is better to act than to be excited, act quickly, we will reply you as soon as we see your message.We have an excellent Aluminum Profile Machining Center, specializing in the production of parts, with many years of experience, fast processing speed, guaranteed material, high precision, and high-precision testing instruments to ensure that each product meets the standard.

Contact Now

There are many manufacturers for batch CNC processing of aluminum alloys, but few can do as much as Longwang to assist customers and solve problems in a timely manner. Customers and manufacturers are actually on the same front line, and only through mutual assistance and cooperation can they become stronger.

Contact Now

High-quality Aluminum Steel Machining, focusing on R&D, manufacturing, processing and sales of aluminum alloy products. The materials we produce are all real materials with guaranteed quality. Turning refers to a part of lathe processing and mechanical processing. Lathe processing mainly uses turning tools to turn rotating workpieces.

Contact Now