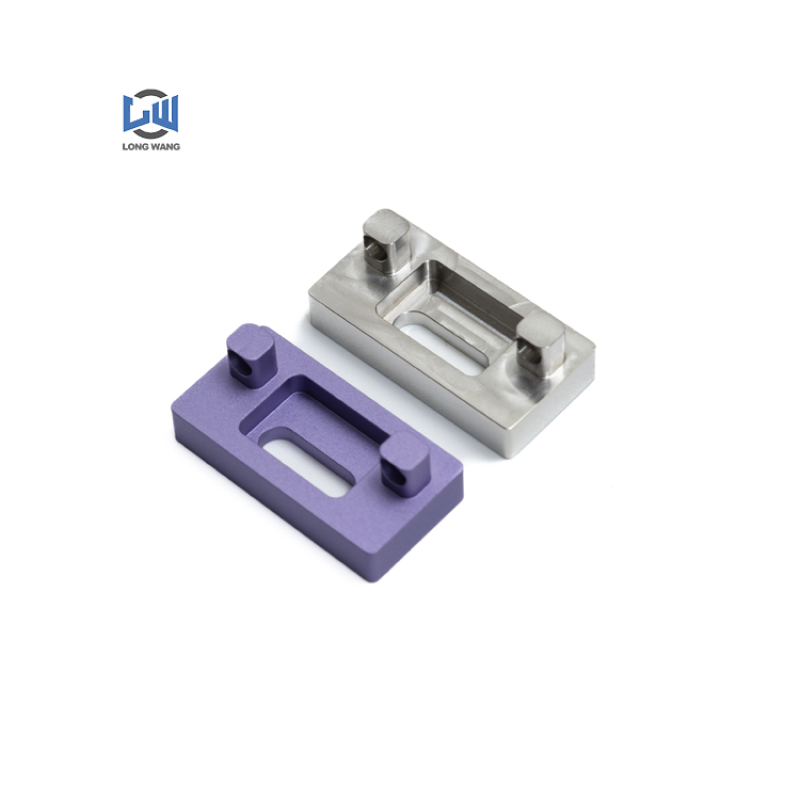

We have CNC Aluminum Keyboard for sale, many authoritative certifications, safety and quality let you rest assured, you can get the certificates, and you can check them online. Most of our products are processed products, please consult us for details. We carefully select the material, the surface is smooth, the hardness is high and the toughness is high, and the service life is long.The CNC Aluminum Keyboard Case we produce is stable in structure, easy to install and use, saves time and effort, and has many applications.

Contact Now

We support a variety of optional specifications, and the processing of drawings can be reasonably customized according to the requirements of customers. We support customized processing of incoming materials and samples, and customized keyboard cnc machining aluminum. We are a word-of-mouth manufacturer, you can choose with confidence and provide customers with high-quality prices.We specialize in custom machining of CNC lathe machining parts, such as custom aluminum keyboard. Professional hepatitis A function long.

Contact Now

We have CNC Aluminum Keyboard Cases of different materials on sale, with complete production equipment, strong overall strength, and a complete and scientific quality management system. We are a professional manufacturer of hardware spare parts and finished product assembly. We focus on providing hardware mold manufacturing, aluminum alloy die castings.If you need a different CNC Keyboard Design, we are an honest merchant with reliable quality, good quality and fast delivery. We also integrate a series of production processes such as design, manufacturing, molding and assembly.

Contact Now

We support a variety of optional specifications, and the processing of drawings can be reasonably customized according to the requirements of customers. We support customized processing of incoming materials and samples, and customized keyboard cnc machining aluminum. We are a word-of-mouth manufacturer, you can choose with confidence and provide customers with high-quality prices.We specialize in custom machining of CNC lathe machining parts, such as custom aluminum keyboard. Professional hepatitis A function long.

Contact Now

We have a professional technical team, imported processing equipment, advanced measuring instruments, parts processing, look for us. We have CNC Aluminum Keyboard Case production. Quality is the life of our company, we strictly implement the quality management policy, the delivery period is short, and the delivery is fast.We are factory direct sales, there is no middleman to make the difference, and the larger quantity is more favorable. We have more professional technical backbones to professionally solve your various problems about CNC Keyboard Design.

Contact Now

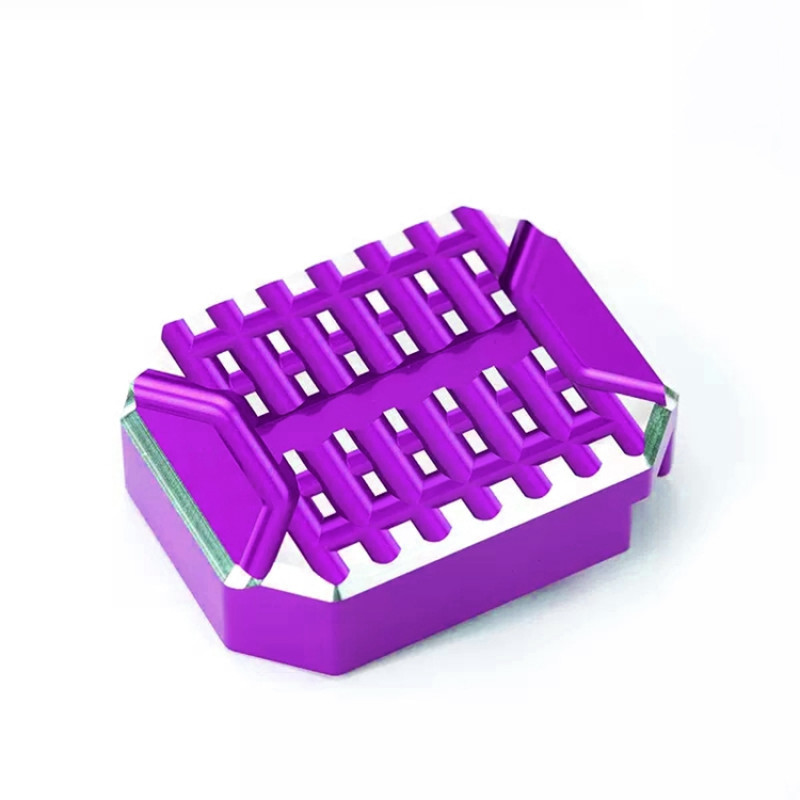

This is a high-quality Mini Computer Enclosure Parts, this case is anti-interference, solid structure and good heat dissipation. We are the source factory, the equipment of the industrial control box, and support customization. Industrial automation mini computer case. We have rich experience in industrial control equipment and processing production.We support customization with drawings and samples. Products with Sheet Metal Fabrication are all physical factories with affordable prices, and there is no middleman to make the difference.

Contact Now

We provide high-quality Aluminum Cnc Machining Service, powerful manufacturers, and professional recommendations. Compressive and wear-resistant technology, cold and heat resistant. Fine workmanship, corrosion resistance. Various specifications, fine craftsmanship, pressure and wear resistance, compact structure, and long-lasting durability.

Contact Now

Industrial Equipment Chassis Cabinet Enclosure, Precision Sheet Metal Cabinet is for sale. Support different non-standard parts processing, stamping parts processing. Excellent material, long service life, suitable for various industries such as industry. Our high-quality craftsmanship, traditional technology, and considerate service for you. We have a set of production system.Sheet Metal Fabrication supports processing of arbitrary shapes, our cutting precision is high, suitable for high-precision processing of various materials.

Contact Now

Automotive CNC Machining is an essential component in manufacturing and industrial environments. These parts are designed to work with CNC machines to automate various tasks and increase productivity. Some common CNC automation components include spindles, tool holders, CNC controllers, linear guides, and servo motors.Our RC Car Parts can be sold wholesale individually or as part of a complete CNC system. They are available from various manufacturers and suppliers and can be customized to meet specific machine and application requirements.If you need CNC Keyboard, you can also contact us.

Contact Now

Mechanical keyboard CNC machining is one of Longwang's main businesses. With years of industry experience, Longwang can meet the processing needs of aluminum alloy precision parts for a large number of customers. The mature CNC machining process empowers the company's products.

Contact Now

We have cnc machining aluminum for sale, carefully designed, reasonable collocation of various processes, working attitude of excellence, mature and stable processing technology, so as to fully guarantee the high quality and high performance of the product. We have complete certificates, please rest assured to buy. Provide customers with excellent products. We have a complete quality inspection system.A variety of aluminum machining parts of different specifications are also available for sale.

Contact Now

There are 7075 Aluminum Machining for sale, we are a manufacturer supplying and operating with integrity. Various specifications, support customization. Our years of industry production experience is trustworthy. We pay attention to details, select materials, and considerate service. Our factory supplies, the quality is trustworthy. Our company has advanced equipment and faces customers with high-quality services.If you need Machining Aluminum Alloys, we support customization and wholesale.

Contact Now

We have Aluminum Cnc Online for sale, machining different parts, high quality machining process. With rich industry experience, we win the market with quality and reputation with service. Fast production cycle, technological innovation, advanced technology, source of strength factory, quality assurance, advanced numerical control equipment, perfect after-sales service.We have different Types Of Aluminum For Machining production, as long as you need, we can customize. We also support drawing production and sample customization.

Contact Now

Professional Aluminum Machining is all on our website, we support customization more, we have a large stock, and support wholesale. If you customize a large quantity, we also have a price discount. It is better to act than to be excited, act quickly, we will reply you as soon as we see your message.We have an excellent Aluminum Profile Machining Center, specializing in the production of parts, with many years of experience, fast processing speed, guaranteed material, high precision, and high-precision testing instruments to ensure that each product meets the standard.

Contact Now

We have advanced machinery and equipment, professional technicians, short construction period, every step of the details are in place, and we will create high-quality products wholeheartedly. Mature processing technology can effectively guarantee the pass rate of products and the stability of delivery. Advanced equipment and skilled technology can effectively guarantee the speed of product delivery.We have CNC machining for parts machining of different materials, custom and wholesale. Support steel machining, aluminum machining.

Contact Now

We produce Aluminum Parts Processing Density of different specifications, the material is guaranteed, and products with special quality requirements, we also carry out full inspection. Good inspection equipment and skilled inspectors ensure the quality of our products! It can be customized on demand, manufacturers love direct sales, and the quality is stable. Our professional quality.Factory direct sales, real materials, Aluminum Parts Processing Design, complete specifications and models, can be processed and customized.

Contact Now

Some Aluminum Machining Near Me, a lot of machining is actually near us, but we can't find what suits our needs for various reasons. Do you have such troubles? You might as well go to our website to have a look, we have many different types of parts processing. All are processed by professional CNC.Like Aluminum Cutting Near Me, some cutting of metal parts, in fact, we also sell them. Because we have advanced production equipment, you can contact us if you are interested. We have technological innovation, fast processing speed, high-quality service, and create high-quality products.

Contact Now

We have many years of processing experience, good product quality, fast processing speed and high precision, professional service, cnc aluminum turning, professional processing equipment, and more excellent processing. Complete technology, one-stop service. The processing of multiple CNC machines can meet the product needs of various materials from proofing to mass production, from plastic to metal.The parts processed by cnc aluminum turning machining are of higher quality. We have abundant materials and high-precision quality. Customer satisfaction is our driving force.

Contact Now

Common Aluminum Machining has many years of processing experience and has been engaged in metal processing for many years. The price is reasonable, the delivery is fast, and the cost performance is high. Welcome to consult. We have strong technical strength, rigorous process, non-standard customization, excellent price, and perfect service system. Welcome to consult.In addition to processing and producing parts, we also support Cutting Discs For Aluminum, which supports cutting of different parts.

Contact Now

We focus on creating high-precision quality, and customer satisfaction is everything to us. Hardware parts, lathe processing, non-standard customization. Fine processing, exquisite workmanship, fast delivery, a variety of Anodized Aluminum Machining, fast quotation, high-precision quality, and reasonable price. Support map customization to meet your various needs.High-quality products, considerate service. Shorten the factory, we are factory direct sales, there is no middleman to make the price difference.

Contact Now

The product is easy to install, sturdy and reliable. High-quality materials, high-quality aluminum alloy, and die-casting technology make the product more durable. Complete specifications, various types, support customization. Anti-slip design, exquisite workmanship, surface treatment. We have a number of technical support, product quality assurance, star service, efficient logistics and transportation.We have many years of experience in CNC machining. Process concentration, automation, high flexibility, and strong capabilities are the characteristics of CNC machining.

Contact Now

We have professional automatic lathe processing and CNC lathe processing, including Aluminum Parts Processing Buy, turning and milling composite machining production and collectors. The source manufacturer has stable supply and guaranteed quality. Arbitrary shape, complete specifications, support to map customization. We can process and customize all kinds of precision parts according to the requirements of customers.We have Aluminum Parts Processing Custom.

Contact Now

There are many manufacturers for batch CNC processing of aluminum alloys, but few can do as much as Longwang to assist customers and solve problems in a timely manner. Customers and manufacturers are actually on the same front line, and only through mutual assistance and cooperation can they become stronger.

Contact Now

Aluminum Machining processing of aluminum alloy CNC parts is an automatic processing method of aluminum alloy parts using CNC machine tools. As a commonly used material with light weight, high strength and good corrosion resistance, aluminum alloy has been widely used in aerospace, automobile, electronics, machinery and other fields.We can select the appropriate aluminum alloy material according to the RC Car Parts part drawing, and then cut the material into a blank that meets the processing size of the part.

Contact Now