Automotive CNC Machining can be made from a variety of materials including metals, plastics and composites. Some common materials used include aluminum, stainless steel, brass, and plastics such as polycarbonate, nylon, and acetal. Examples of parts include gears, bearings, shafts, brackets, and housings. These components are used in various automation systems such as robotics, assembly lines and packaging machinery.One of the main advantages is that they can be produced with high precision and repeatability. It can also be made into CNC Camera Parts.

Contact Now

We have 3-axis, 4-week, 5-axis CNC precision machined parts. Centering machine processing, can be surface treated. We are authentic guarantee, with after-sales attentive service, factory direct sales. We are now designing hardware precision parts in many fields, including automotive, marine, aerospace and other accessories. We mainly focus on mid-to-high-end products.CNC Turning automatically processes the processed parts according to the pre-programmed processing program.

Contact Now

CNC machined strut spacers are small blocks that are placed on top of the strut assembly in order to lift the vehicle's suspension. These spacers are typically made out of aluminum or steel.CNC machined 6061 T6 (T6 refers to the temper or hardness of the material) hub parts are components that are used in the assembly of a vehicle's wheel hub.

Contact Now

Good quality, good service, fine workmanship, quality assurance, to provide you with a better experience. Automotive CNC Machining Online, various models, exquisite workmanship, spot wholesale, after-sales guarantee. There are various product specifications and support cutting. For more details, please contact us. The product quality is strictly inspected, and all products are shipped manually.Our Automotive CNC Machining is of good quality, strictly inspected, and all shipments are manually inspected, so that the goods you receive are perfect and undamaged.

Contact Now

5-axis CNC machining helps save more time than other traditional types. Most parts manufactured in CNC workshops must be machined on five surfaces. 5-axis CNC machining helps to efficiently and quickly complete work in production. In a 5-axis machining machine, the position of the parts is relatively close to the cutting tool. The last two axes will allow the use of short tools with less vibration, which will significantly affect the quality of the surface finish.

Contact Now

We build a good reputation with quality and service, CNC Machining one-stop processing and customization services, excellent materials can be processed and customized, and have a long service life. A variety of specifications can be selected, and the material can be customized. We carefully select materials, quality assurance, durable.

Contact Now

With the popularity of four-wheel drive vehicles, the demand for off-road performance is also increasing. For off-road enthusiasts, modification is also an inevitable topic. Among numerous modifications, Strut Spacers is a highly regarded one.

Contact Now

We have advanced CNC machining equipment for CNC product parts processing, which efficiently completes various small part customization requirements. The process flow strictly follows the ISO9001 standard, ensuring that the quality of each product meets high standards and fast delivery.Precision CNC machining of complex geometric shapes and providing support for your mechanical engineers in design, validation, and engineering testing. We provide customized processing parts for multiple industries: home appliances, automobiles, electronics, machinery, medical equipment, and robots.

Contact Now

A customized machined aluminum base is a type of component that is made using CNC machining processes. It is typically used as a foundation or support for other parts or products and is often found in various industrial settings such as manufacturing, aerospace, and robotics.The aluminum material used in the machining process is typically a high-strength alloy, such as 6061-T6 aluminum.

Contact Now

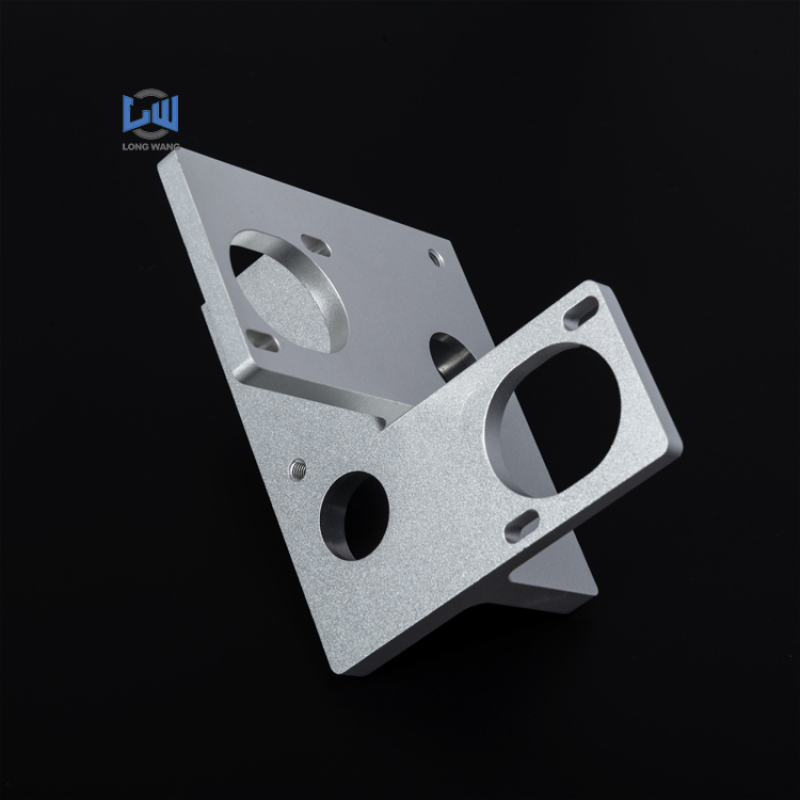

This product is made of AL6061 aluminum alloy and precision machined on a CNC machining center. The structure of the product is relatively simple, with high surface requirements. After mirror polishing and hard oxidation, it achieves extremely high appearance effects; In order to ensure product quality, Longwang's engineering team provides customers with the best precision machining solutions from design to manufacturing.In addition, it is also important to pay attention to product quality.

Contact Now

We have professional automatic lathe processing and CNC lathe processing, including Aluminum Parts Processing Buy, turning and milling composite machining production and collectors. The source manufacturer has stable supply and guaranteed quality. Arbitrary shape, complete specifications, support to map customization. We can process and customize all kinds of precision parts according to the requirements of customers.We have Aluminum Parts Processing Custom.

Contact Now

In CNC parts precision machining, the design of the part is created using computer-aided design (CAD) software. This design is then translated into a set of instructions for the CNC machine using computer-aided manufacturing (CAM) software. The instructions are sent to the machine's controller, which controls the movement of the cutting tool and the positioning of the workpiece in order to create the desired shape.CNC parts precision machining can be used to produce a wide variety of parts, from small and simple components to large and complex assemblies.

Contact Now

The work efficiency of CNC parts machining is higher. Nowadays, CNC machine tools can process multiple machining surfaces simultaneously. Compared with ordinary processing, it is precise and efficient, and CNC processed products have higher quality.CNC precision parts processing plays an irreplaceable role in the development of new products. In general, even complex parts can be produced and processed through code programming.The automation level of CNC precision parts processing is very high, saving a lot of manpower.

Contact Now

In this fiercely competitive social development trend, everything seems to be faster, and the CNC processing of large quantities of aluminum parts is also the same.

Contact Now

CNC turning processing parts is a modern mechanical processing method. Using computer numerical control technology to control lathes for cutting processing, parts with various shapes, high precision and stable quality can be processed. CNC turning parts are widely used in aviation, aerospace, automobiles, ships and other fields.In order to obtain high-quality CNC turning parts, it is necessary to select high-quality raw materials and sophisticated processing equipment.

Contact Now

Aluminum alloy processing is a very important part of modern manufacturing, and customized processing is an inevitable choice to meet specific needs. CNC aluminum alloy processing, as a high-precision, high-efficiency, and highly flexible processing method, is increasingly favored by people.If you have a need for aluminum alloy parts, customized processing is definitely the best choice!

Contact Now

Longwang is a high-tech enterprise mainly engaged in precision mechanical parts processing, non-standard parts processing, and titanium alloy processing. It provides various types of precision mechanical parts processing and fixture processing for solar energy equipment, medical equipment, electronic equipment, optoelectronic communication equipment, and office automation equipment. It has rich experience in high-precision bowl alloy parts processing, shaft parts processing, semiconductor equipment parts processing, and other aspects.

Contact Now

Aluminum alloy milling CNC refers to the process of using a computer numerical control (CNC) machine to mill or cut aluminum alloy material into a desired shape or form. This process involves using a rotating cutting tool to remove material from the workpiece, guided by a computer program that controls the movement of the cutting tool. Aluminum alloy milling CNC is commonly used in manufacturing settings to produce complex and precise parts for a variety of industries, including aerospace, automotive, and engineering.

Contact Now

The materials commonly processed by lathes are free-cutting steel and copper. The free-cutting steel is made of materials with high sulfur content S and phosphorus content P. Sulfur and manganese exist in the form of manganese sulfide in the steel.The commonly used material for modern lathe machining is aluminum alloy material, which has a significantly reduced density compared to iron and steel materials. Moreover, lathe machining is less difficult, has strong plasticity, and greatly reduces product weight. This also greatly shortens the time for lathe machining parts.

Contact Now

We specialize in CNC precision machining of functional prototypes with complex geometric shapes, providing excellent support for your design verification and engineering testing. For example, optical parts with detail orientation, and aluminum housing parts with complex structures. With 15 years of aluminum alloy CNC machining experience, we are a one-stop service manufacturer specializing in the processing of aluminum components such as audio aluminum alloy housings, aluminum alloy housings, aluminum alloy cavities, and high-quality surface treatment.

Contact Now

CNC turning mechanical shaft is a mechanical shaft produced by CNC lathe. CNC turning is a modern machining method that uses a CNC system to control tools on a lathe to process workpieces. CNC turning mechanical shafts are usually machined from metallic materials such as steel, aluminum, copper, etc.

Contact Now

The double caliper rear bracket after CNC machining is a high-precision mechanical component widely used in the fields of automobile manufacturing and modification. The rear bracket can simultaneously install two brake calipers, making the car's braking system more stable and reliable, improving driving safety.In addition to the automotive manufacturing and modification fields, the rear bracket can also be applied to other mechanical equipment and engineering fields.

Contact Now