We have CNC Aluminum Keyboard Cases of different materials on sale, with complete production equipment, strong overall strength, and a complete and scientific quality management system. We are a professional manufacturer of hardware spare parts and finished product assembly. We focus on providing hardware mold manufacturing, aluminum alloy die castings.If you need a different CNC Keyboard Design, we are an honest merchant with reliable quality, good quality and fast delivery. We also integrate a series of production processes such as design, manufacturing, molding and assembly.

Contact Now

Indispensable to our excellent team is a complete scientific management system. With different Sheet Metal Bending Parts for sale, we have many years of experience in processing. We have many years of experience, professional R&D and design, support for customization, and accurate delivery. Professional workflow, rapid prototyping design and machining services company.Made with our advanced Sheet Metal Bending Process. If you need special requirements for customization, our company can provide customized specifications.

Contact Now

We produce Aluminum Parts Processing Density of different specifications, the material is guaranteed, and products with special quality requirements, we also carry out full inspection. Good inspection equipment and skilled inspectors ensure the quality of our products! It can be customized on demand, manufacturers love direct sales, and the quality is stable. Our professional quality.Factory direct sales, real materials, Aluminum Parts Processing Design, complete specifications and models, can be processed and customized.

Contact Now

We provide high-quality Aluminum Cnc Machining Service, powerful manufacturers, and professional recommendations. Compressive and wear-resistant technology, cold and heat resistant. Fine workmanship, corrosion resistance. Various specifications, fine craftsmanship, pressure and wear resistance, compact structure, and long-lasting durability.

Contact Now

We have cnc machining aluminum for sale, carefully designed, reasonable collocation of various processes, working attitude of excellence, mature and stable processing technology, so as to fully guarantee the high quality and high performance of the product. We have complete certificates, please rest assured to buy. Provide customers with excellent products. We have a complete quality inspection system.A variety of aluminum machining parts of different specifications are also available for sale.

Contact Now

The product is easy to install, sturdy and reliable. High-quality materials, high-quality aluminum alloy, and die-casting technology make the product more durable. Complete specifications, various types, support customization. Anti-slip design, exquisite workmanship, surface treatment. We have a number of technical support, product quality assurance, star service, efficient logistics and transportation.We have many years of experience in CNC machining. Process concentration, automation, high flexibility, and strong capabilities are the characteristics of CNC machining.

Contact Now

There are 7075 Aluminum Machining for sale, we are a manufacturer supplying and operating with integrity. Various specifications, support customization. Our years of industry production experience is trustworthy. We pay attention to details, select materials, and considerate service. Our factory supplies, the quality is trustworthy. Our company has advanced equipment and faces customers with high-quality services.If you need Machining Aluminum Alloys, we support customization and wholesale.

Contact Now

In the production process, CNC aluminum alloy customized parts need to go through multiple processes, including design, cutting, drilling, processing, etc., and the accuracy and quality of each process are extremely important. Therefore, high-quality CNC processing manufacturers are needed to ensure product quality and accuracy.

Contact Now

We have Aluminum Cnc Online for sale, machining different parts, high quality machining process. With rich industry experience, we win the market with quality and reputation with service. Fast production cycle, technological innovation, advanced technology, source of strength factory, quality assurance, advanced numerical control equipment, perfect after-sales service.We have different Types Of Aluminum For Machining production, as long as you need, we can customize. We also support drawing production and sample customization.

Contact Now

We have a professional technical team, imported processing equipment, advanced measuring instruments, parts processing, look for us. We have CNC Aluminum Keyboard Case production. Quality is the life of our company, we strictly implement the quality management policy, the delivery period is short, and the delivery is fast.We are factory direct sales, there is no middleman to make the difference, and the larger quantity is more favorable. We have more professional technical backbones to professionally solve your various problems about CNC Keyboard Design.

Contact Now

Professional Aluminum Machining is all on our website, we support customization more, we have a large stock, and support wholesale. If you customize a large quantity, we also have a price discount. It is better to act than to be excited, act quickly, we will reply you as soon as we see your message.We have an excellent Aluminum Profile Machining Center, specializing in the production of parts, with many years of experience, fast processing speed, guaranteed material, high precision, and high-precision testing instruments to ensure that each product meets the standard.

Contact Now

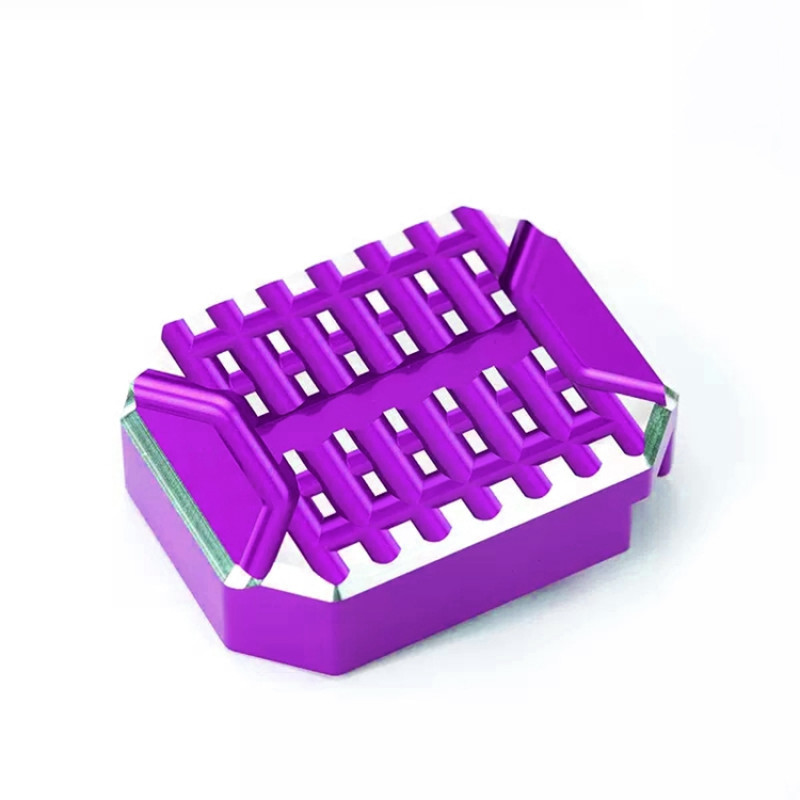

This product is made of AL6061 aluminum alloy and precision machined on a CNC machining center. The structure of the product is relatively simple, with high surface requirements. After mirror polishing and hard oxidation, it achieves extremely high appearance effects; In order to ensure product quality, Longwang's engineering team provides customers with the best precision machining solutions from design to manufacturing.In addition, it is also important to pay attention to product quality.

Contact Now

Precision CNC machining of complex geometric shapes and providing support for your mechanical engineers in design, validation, and engineering testing. We provide customized processing parts for multiple industries: home appliances, automobiles, electronics, machinery, medical equipment, and robots.

Contact Now

We are a cutting-edge team with technical advantages, cost advantages, and service advantages. The company's main business is different hardware CNC processing, as well as Aluminum Machining Near Me. We are determined to produce good products and deliver on time. In line with the spirit of perseverance, rigor, truth-seeking, and pioneering spirit, we have become a modern enterprise integrating design, production and sales.New processing technology, programming processing can process all the functions required for full-featured parts, including threaded holes and accurate flat surfaces.

Contact Now

We support a variety of optional specifications, and the processing of drawings can be reasonably customized according to the requirements of customers. We support customized processing of incoming materials and samples, and customized keyboard cnc machining aluminum. We are a word-of-mouth manufacturer, you can choose with confidence and provide customers with high-quality prices.We specialize in custom machining of CNC lathe machining parts, such as custom aluminum keyboard. Professional hepatitis A function long.

Contact Now

We provide one-stop custom processing services, originating from processing, not limited to processing, with Aluminum Machining, dedicated for many years, only to do a good job of every piece of hardware. We have complete equipment, professional machining centers, CNC Machining, and various equipment. Professional technology, the factory has a professional planning and design team to plan and produce cnc automation parts for customers, provide high-quality solutions to meet customer customization requirements.

Contact Now

We specialize in CNC precision machining of functional prototypes with complex geometric shapes, providing excellent support for your design verification and engineering testing. For example, optical parts with detail orientation, and aluminum housing parts with complex structures. With 15 years of aluminum alloy CNC machining experience, we are a one-stop service manufacturer specializing in the processing of aluminum components such as audio aluminum alloy housings, aluminum alloy housings, aluminum alloy cavities, and high-quality surface treatment.

Contact Now

A tripod lock is a component used in photography tripods that helps to secure the legs in place for stability. CNC machining can be used to manufacture tripod locks with high precision and consistency.The process of CNC machining a tripod lock begins with designing the component in CAD software. This design is then translated into a set of instructions for the CNC machine using CAM software.

Contact Now

Common Aluminum Machining has many years of processing experience and has been engaged in metal processing for many years. The price is reasonable, the delivery is fast, and the cost performance is high. Welcome to consult. We have strong technical strength, rigorous process, non-standard customization, excellent price, and perfect service system. Welcome to consult.In addition to processing and producing parts, we also support Cutting Discs For Aluminum, which supports cutting of different parts.

Contact Now

Our RC Car Parts use computer-aided design software (such as SolidWorks, AutoCAD, etc.) to design a 3D model of the parts that need to be manufactured. This process needs to take into account the size, shape, material and other factors of the part. Import the designed 3D model into CAM software (such as MasterCAM, CATIA, etc.), set tools, cutting parameters, etc., and generate CNC machining programs.According to your design drawings and CNC codes, we can choose suitable materials, such as metal, plastic or wood, and then cut them to the appropriate size and shape.

Contact Now

For CNC Machining of mechanical parts, we support the provision of product design schemes, drawings and samples, and one-stop services for surface treatment and custom processing. Our company mainly provides all kinds of hardware structural parts, mainly CNC Turning machining, stamping processing, laser marking and surface post-treatment process station service. Multiple high-precision and efficient CNC lathes and branded machining centers support Aluminum Machining, parts processing, and various processing.

Contact Now

We have CNC Aluminum Keyboard for sale, many authoritative certifications, safety and quality let you rest assured, you can get the certificates, and you can check them online. Most of our products are processed products, please consult us for details. We carefully select the material, the surface is smooth, the hardness is high and the toughness is high, and the service life is long.The CNC Aluminum Keyboard Case we produce is stable in structure, easy to install and use, saves time and effort, and has many applications.

Contact Now

Some Aluminum Machining Near Me, a lot of machining is actually near us, but we can't find what suits our needs for various reasons. Do you have such troubles? You might as well go to our website to have a look, we have many different types of parts processing. All are processed by professional CNC.Like Aluminum Cutting Near Me, some cutting of metal parts, in fact, we also sell them. Because we have advanced production equipment, you can contact us if you are interested. We have technological innovation, fast processing speed, high-quality service, and create high-quality products.

Contact Now

We have advanced machinery and equipment, professional technicians, short construction period, every step of the details are in place, and we will create high-quality products wholeheartedly. Mature processing technology can effectively guarantee the pass rate of products and the stability of delivery. Advanced equipment and skilled technology can effectively guarantee the speed of product delivery.We have CNC machining for parts machining of different materials, custom and wholesale. Support steel machining, aluminum machining.

Contact Now