Aluminum Machining processing of aluminum alloy CNC parts is an automatic processing method of aluminum alloy parts using CNC machine tools. As a commonly used material with light weight, high strength and good corrosion resistance, aluminum alloy has been widely used in aerospace, automobile, electronics, machinery and other fields.We can select the appropriate aluminum alloy material according to the RC Car Parts part drawing, and then cut the material into a blank that meets the processing size of the part.

Contact Now

Custom CNC Milling Machining Parts, we are professional, support personalized customization, can cut to any size, and provide personalized services. Will adhere to the customer-oriented, quality-oriented strategy. Welcome friends from all walks of life to visit, guide and negotiate business. We focus on customization and establish stable cooperative relationships with many cooperative merchants.We have excellent equipment for processing, and can provide one-stop service from aluminum material production to processing. Applicable to a wide range of scenarios.

Contact Now

Aluminum alloy milling CNC refers to the process of using a computer numerical control (CNC) machine to mill or cut aluminum alloy material into a desired shape or form. This process involves using a rotating cutting tool to remove material from the workpiece, guided by a computer program that controls the movement of the cutting tool. Aluminum alloy milling CNC is commonly used in manufacturing settings to produce complex and precise parts for a variety of industries, including aerospace, automotive, and engineering.

Contact Now

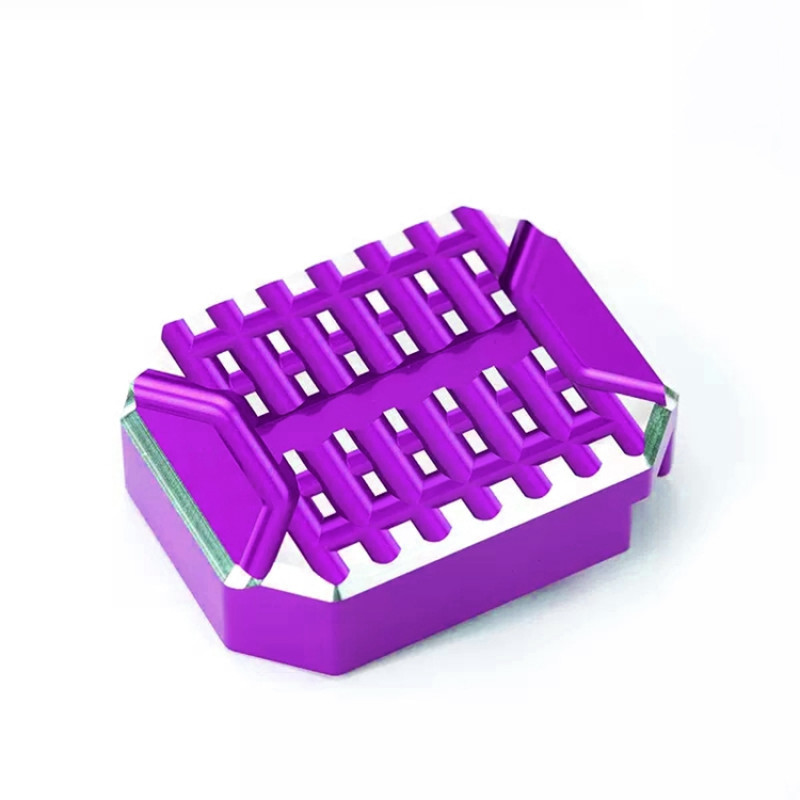

This product is made of AL6061 aluminum alloy and precision machined on a CNC machining center. The structure of the product is relatively simple, with high surface requirements. After mirror polishing and hard oxidation, it achieves extremely high appearance effects; In order to ensure product quality, Longwang's engineering team provides customers with the best precision machining solutions from design to manufacturing.In addition, it is also important to pay attention to product quality.

Contact Now

Aluminum alloy processing is a very important part of modern manufacturing, and customized processing is an inevitable choice to meet specific needs. CNC aluminum alloy processing, as a high-precision, high-efficiency, and highly flexible processing method, is increasingly favored by people.If you have a need for aluminum alloy parts, customized processing is definitely the best choice!

Contact Now

The product is easy to install, sturdy and reliable. High-quality materials, high-quality aluminum alloy, and die-casting technology make the product more durable. Complete specifications, various types, support customization. Anti-slip design, exquisite workmanship, surface treatment. We have a number of technical support, product quality assurance, star service, efficient logistics and transportation.We have many years of experience in CNC machining. Process concentration, automation, high flexibility, and strong capabilities are the characteristics of CNC machining.

Contact Now

Are you looking for a reliable and fast aluminum alloy CNC processing service manufacturer? Dongguan Longwang Hardware Co.,Ltd. was established in 2008 and is located in Changan Town, Dongguan, with convenient transportation. It is a production-oriented enterprise mainly engaged in the processing of aluminum alloy precision parts. Specializing in the production, processing, and manufacturing of non-standard precision hardware CNC parts.

Contact Now

Aluminum machining is an important manufacturing process, and 4-axis aluminum milling is a common way of doing it. Aluminum alloy is a lightweight, high-strength metal material widely used in aviation, automobiles, electronics, construction and other fields. The processing of aluminum alloy parts is a very important part. When machining aluminum alloy parts, using a 4-axis milling machine can achieve efficient and precise machining.Compared with traditional 3-axis milling, this method can more accurately process complex shapes and structures, and can also improve production efficiency.

Contact Now

We specialize in CNC precision machining of functional prototypes with complex geometric shapes, providing excellent support for your design verification and engineering testing. For example, optical parts with detail orientation, and aluminum housing parts with complex structures. With 15 years of aluminum alloy CNC machining experience, we are a one-stop service manufacturer specializing in the processing of aluminum components such as audio aluminum alloy housings, aluminum alloy housings, aluminum alloy cavities, and high-quality surface treatment.

Contact Now

The importance of product quality and accuracy for precision parts processing manufacturers is self-evident. In the production process, it is particularly important to pay attention to the details. Small details determine success or failure. Not only should we have the spirit of craftsmanship, but we should also truly achieve precision machining and make our good products.

Contact Now

Aluminum Machining usually requires the following steps:Design and manufacture CAD drawings or 3D models of aluminum parts.Choose the appropriate aluminum alloy material and processing technology, such as milling, drilling, turning, etc.CNC Machining with CNC machine or manual machine.Surface treatment of aluminum parts such as polishing, painting or anodizing etc.Perform quality control to ensure aluminum parts meet specifications.When processing aluminum parts, you need to pay attention to the following points:Choose the appropriate aluminum alloy material.

Contact Now

We provide one-stop custom processing services, originating from processing, not limited to processing, with Aluminum Machining, dedicated for many years, only to do a good job of every piece of hardware. We have complete equipment, professional machining centers, CNC Machining, and various equipment. Professional technology, the factory has a professional planning and design team to plan and produce cnc automation parts for customers, provide high-quality solutions to meet customer customization requirements.

Contact Now

Aluminum Machining can use various CNC machining equipment, such as CNC lathes, CNC milling machines, CNC machining centers, etc. These devices can realize high-speed and high-precision CNC Machining, which greatly improves the efficiency and quality of aluminum parts processing. Aluminum CNC machining refers to the process of using CNC machine tools to process aluminum alloy materials. CNC machining has the advantages of high efficiency, high precision, and good repeatability, and is widely used in the field of aluminum parts manufacturing.

Contact Now

With the continuous advancement and innovation of science and technology, the aircraft industry has developed rapidly in recent years. Among them, UAV technology, as one of the important fields, has become the focus of people's research and attention. In the manufacturing process of drones, aluminum alloy CNC machining parts are more and more widely used.In the manufacturing process of drones, aluminum alloy CNC processing parts are widely used in aircraft shells, chassis, brackets, transmission systems, etc.

Contact Now

We have CNC Aluminum Keyboard Cases of different materials on sale, with complete production equipment, strong overall strength, and a complete and scientific quality management system. We are a professional manufacturer of hardware spare parts and finished product assembly. We focus on providing hardware mold manufacturing, aluminum alloy die castings.If you need a different CNC Keyboard Design, we are an honest merchant with reliable quality, good quality and fast delivery. We also integrate a series of production processes such as design, manufacturing, molding and assembly.

Contact Now

The application of CNC precision electronic manufacturing technology in the field of unmanned aerial vehicles is becoming increasingly widespread. In the manufacturing process of unmanned aerial vehicles, the unmanned chassis is a very important component. And CNC precision electronic manufacturing technology provides high-quality solutions for the manufacturing of unmanned chassis.CNC precision electronic manufacturing technology can perform precision machining on unmanned chassis through high-precision processing equipment such as CNC machine tools.

Contact Now

For CNC Machining of mechanical parts, we support the provision of product design schemes, drawings and samples, and one-stop services for surface treatment and custom processing. Our company mainly provides all kinds of hardware structural parts, mainly CNC Turning machining, stamping processing, laser marking and surface post-treatment process station service. Multiple high-precision and efficient CNC lathes and branded machining centers support Aluminum Machining, parts processing, and various processing.

Contact Now

Stainless steel refers to a steel alloy that is resistant to chemical corrosion media such as air, steam, water, acids, and alkalis. Stainless steel is widely popular in CNC milling services due to its excellent mechanical properties, providing a large number of precision CNC milling services for industries such as surgical equipment, electronic hardware, stainless steel parts for automobiles, aerospace equipment, and food processing machinery.

Contact Now

High strength, light weight, high assembly precision. Electromagnetic compatibility, cabinet customization. Schematic design, structural simulation. On the premise of satisfying the function, we continue to upgrade the overall lightweight and assembly time. The overall cabinet is made of lightweight aluminum alloy and other materials, making the cabinet light and beautiful while maintaining strength.Sheet Metal Fabrication can customize the creation of different parts and accessories according to your needs. Sheet Metal Enclosure and various small parts.

Contact Now

In the production process, CNC aluminum alloy customized parts need to go through multiple processes, including design, cutting, drilling, processing, etc., and the accuracy and quality of each process are extremely important. Therefore, high-quality CNC processing manufacturers are needed to ensure product quality and accuracy.

Contact Now

We provide high-quality Aluminum Cnc Machining Service, powerful manufacturers, and professional recommendations. Compressive and wear-resistant technology, cold and heat resistant. Fine workmanship, corrosion resistance. Various specifications, fine craftsmanship, pressure and wear resistance, compact structure, and long-lasting durability.

Contact Now

There are many manufacturers for batch CNC processing of aluminum alloys, but few can do as much as Longwang to assist customers and solve problems in a timely manner. Customers and manufacturers are actually on the same front line, and only through mutual assistance and cooperation can they become stronger.

Contact Now

We have professional automatic lathe processing and CNC lathe processing, including Aluminum Parts Processing Buy, turning and milling composite machining production and collectors. The source manufacturer has stable supply and guaranteed quality. Arbitrary shape, complete specifications, support to map customization. We can process and customize all kinds of precision parts according to the requirements of customers.We have Aluminum Parts Processing Custom.

Contact Now

Rapid prototyping of aluminum parts is a very promising manufacturing technology, especially for the manufacture of aluminum alloy parts with high precision, small batches and complex shapes. We have Aluminum Machining, which is also a good choice. We have specialized in processing for many years, and there are some challenges in the rapid prototyping of aluminum parts. For example, the cost of aluminum alloy powder is relatively high, and the requirements for equipment are relatively high.

Contact Now